Sorting and recycling system and process for coal-free gasified fine coal

A recovery system and fine-grained coal technology, applied in the direction of mechanical material recovery, recycling technology, flotation, etc., can solve the problems of high energy consumption and poor separation effect of coal slime, achieve low energy consumption, and improve the economic benefits of the whole plant , The effect of ensuring the quality of clean coal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

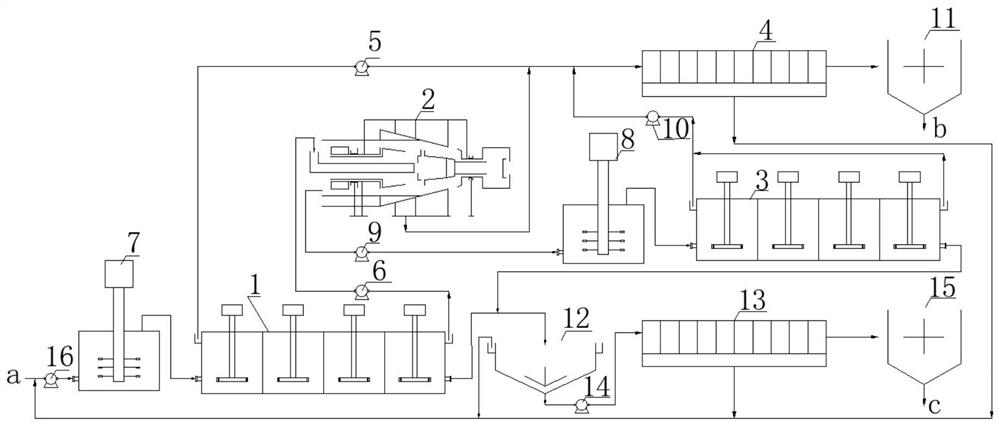

[0041] A specific embodiment of the present invention, such as figure 1As shown in the figure, a separation and recovery system for fine-grained coal without sliming (hereinafter referred to as "separation and recovery system") is disclosed, including a first flotation machine 1, a sedimentation filter centrifuge 2, and a second flotation machine 3 and the first ultra-high pressure filter 4, the first flotation machine 1 is a four-slot flotation machine, and the flotation clean coal in the last two slots of the first flotation machine 1 passes through the sedimentation filter centrifuge 2 for ash reduction and dehydration. The flotation clean coal formed and the flotation clean coal in the last two tanks of the first flotation machine 1 pass through the sedimentation filter centrifuge 2 for ash reduction and dehydration, and the centrifugal liquid formed by the flotation clean coal obtained by the second flotation machine 3 The flotation clean coals in the first two tanks of t...

Embodiment 2

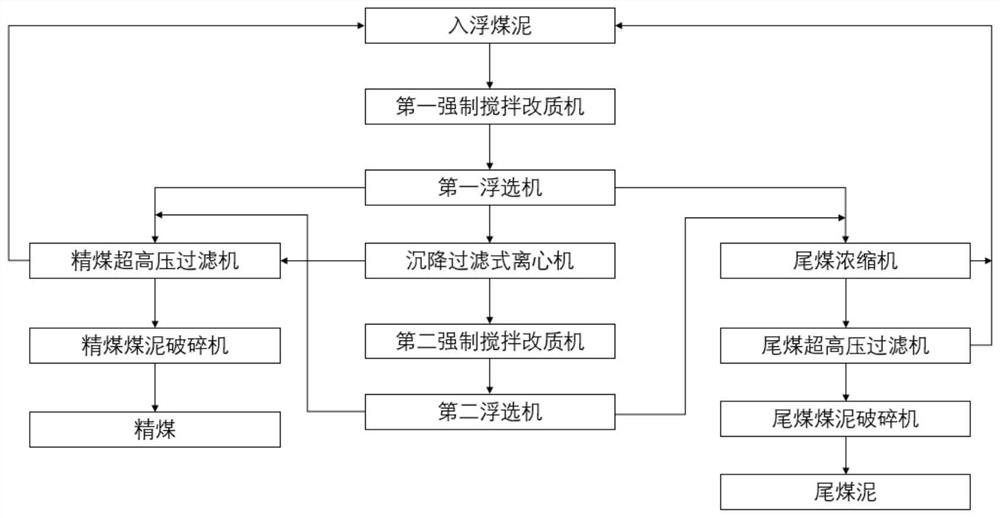

[0086] Another specific embodiment of the present invention, such as image 3 As shown, a sorting and recycling process for non-slimed fine-grained coal is disclosed, using the non-slimed fine-grained coal sorting and recycling system of Example 1, and the steps include:

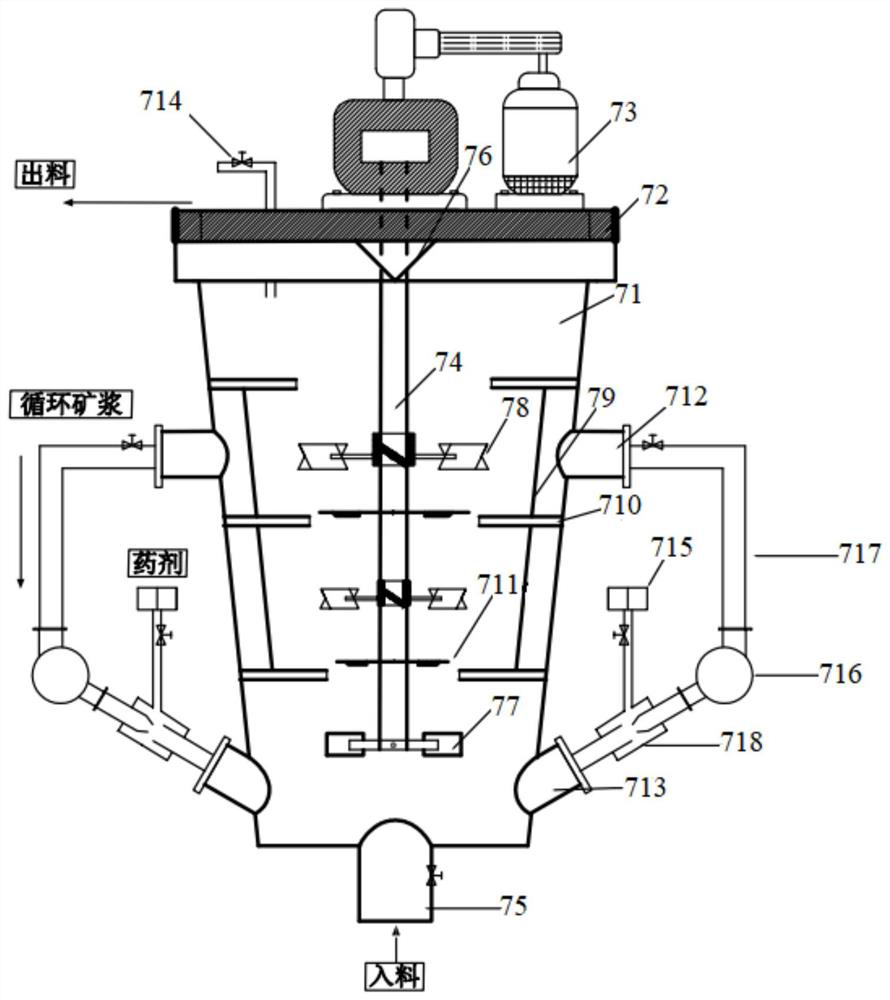

[0087] The floating coal slurry is fed into the first forced stirring and reformer 7 from the bottom by the sixth material pump 16, and the slurry concentration is set at 500g / L. Add a certain amount (500g / t) of collectors (kerosene, diesel oil, etc.) and a certain amount (200g / t) of foaming agents (sec-octanol, MIBC, etc.) according to the characteristics of the floating slime. The pulp is fully conditioned and modified, overflows from the upper discharge end of the first forced stirring and reformer 7, and enters the first flotation machine 1 continuously, uniformly and stably for sorting.

[0088] After the flotation foam clean coal in the first two tanks of the first flotation machine 1 is defoamed, it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com