Water-based fluorine-modified polyester can-making coating and preparation method thereof

A technology of water-based polyester resin and water-based fluorine, applied in polyester coatings, coatings, etc., can solve the problems of affecting the normal use and service life of metal tanks, reducing the sealing performance of coatings, low hardness and flexibility, and achieving low temperature Excellent elasticity, improved coating performance, and improved acid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

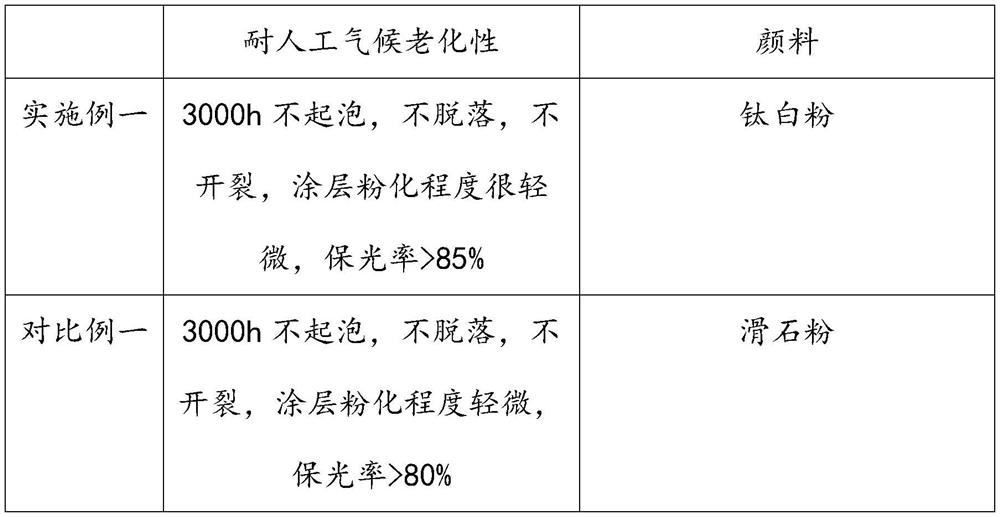

Embodiment 1

[0020] The invention provides a water-based fluorine-modified polyester can coating, which comprises the following raw materials in parts by weight: 20 parts of modified fluorocarbon emulsion, 10 parts of water-based polyester resin, 10 parts of deionized water, 0.2 parts of dispersant, and defoamer 0.2 part, 20 parts of pigments and fillers, 1 part of thickener, 1 part of film-forming aid and 0.2 part of wetting agent.

[0021] The modified fluorocarbon emulsion is prepared by the following method: adding the ultraviolet cross-linked elastic emulsion to the fluorocarbon emulsion, mixing and stirring evenly, and standing for 30 minutes to obtain the modified fluorocarbon emulsion;

[0022] The present invention also proposes a water-based fluorine-modified polyester can coating and a preparation method thereof, comprising the following steps:

[0023] S1, weigh by weight 20 parts of modified fluorocarbon emulsion, 10 parts of water-based polyester resin, 10 parts of deionized ...

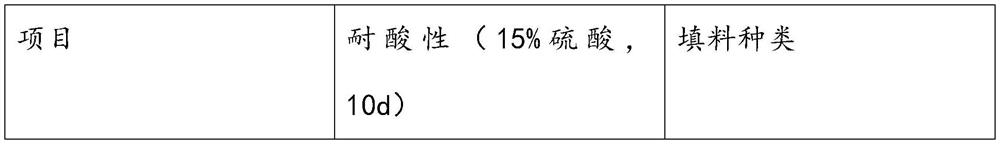

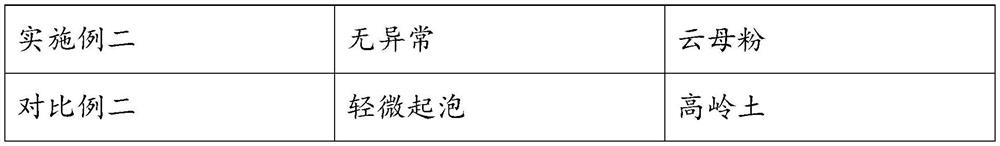

Embodiment 2

[0027] The invention provides a water-based fluorine-modified polyester can coating, which comprises the following raw materials in parts by weight: 20 parts of modified fluorocarbon emulsion, 10 parts of water-based polyester resin, 10 parts of deionized water, 0.2 parts of dispersant, and defoamer 0.2 part, 20 parts of pigments and fillers, 1 part of thickener, 1 part of film-forming aid and 0.2 part of wetting agent.

[0028] The modified fluorocarbon emulsion is prepared by the following method: adding the ultraviolet cross-linked elastic emulsion to the fluorocarbon emulsion, mixing and stirring evenly, and standing for 30 minutes to obtain the modified fluorocarbon emulsion;

[0029] The present invention also proposes a water-based fluorine-modified polyester can coating and a preparation method thereof, comprising the following steps:

[0030] S1, weigh by weight 20 parts of modified fluorocarbon emulsion, 10 parts of water-based polyester resin, 10 parts of deionized ...

Embodiment 3

[0034] The invention provides a water-based fluorine-modified polyester can coating, which comprises the following raw materials in parts by weight: 20 parts of modified fluorocarbon emulsion, 10 parts of water-based polyester resin, 10 parts of deionized water, 0.2 parts of dispersant, and defoamer 0.2 part, 20 parts of pigments and fillers, 1 part of thickener, 1 part of film-forming aid and 0.2 part of wetting agent.

[0035] The modified fluorocarbon emulsion is prepared by the following method: adding the ultraviolet cross-linked elastic emulsion to the fluorocarbon emulsion, mixing and stirring evenly, and standing for 30 minutes to obtain the modified fluorocarbon emulsion, and the fluorocarbon emulsion and ultraviolet cross-linking The mass of the lotion is 1:2.

[0036]The present invention also proposes a water-based fluorine-modified polyester can coating and a preparation method thereof, comprising the following steps:

[0037] S1, weigh by weight 20 parts of modi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com