Essential antistatic thermoplastic polyurethane elastomer and preparation method thereof

A thermoplastic polyurethane and antistatic technology, applied in the field of polyurethane elastomers, can solve the problems affecting the strength and hardness of materials, the decline of antistatic properties, and the complex processing technology, and achieve excellent low-temperature elasticity, long-lasting antistatic properties, and simple processing technology. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

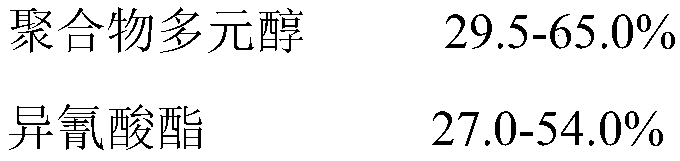

[0034] An intrinsically antistatic thermoplastic polyurethane elastomer made from the following raw materials in the following weight percents:

[0035]

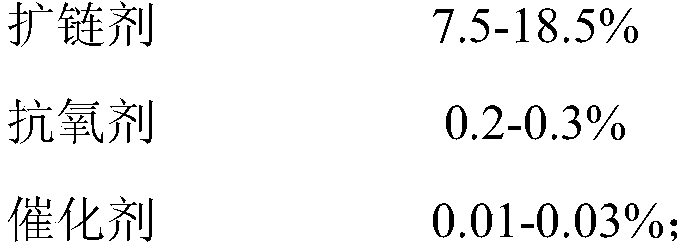

[0036]

[0037] Its preparation method is as follows:

[0038] (1) Polytetrahydrofuran block polyamide 6 copolyethylene glycol (M=1000), antioxidant 1010 and organotin are added in reactor A by weight percentage, nitrogen protection, keep reactor A temperature is 105 ℃, and in Stir well in the reaction kettle A evenly. Add MDI into reactor B by weight percentage, protect the reactor with nitrogen, and keep the temperature of the reactor at 60°C. Add 1,4-butanediol into reactor C according to the weight percentage, protect the reactor with nitrogen, and keep the temperature of the reactor at 55°C.

[0039] (2) After the temperature of each reactor is stabilized, through the perfusion system with precise metering, the raw material components in the reactors A, B and C are accurately metered by the metering pump accordi...

Embodiment 2

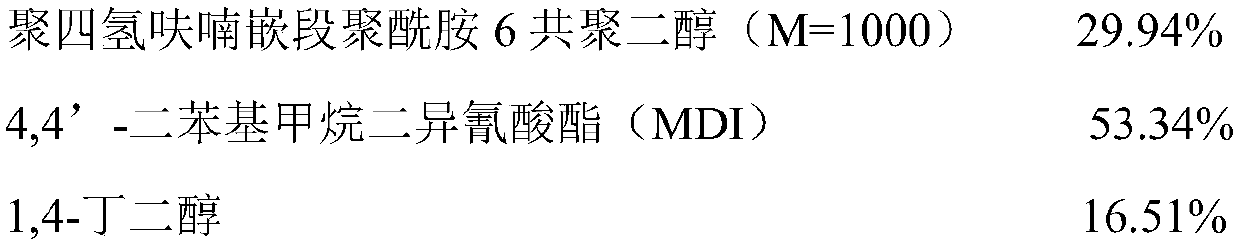

[0041]An intrinsically antistatic thermoplastic polyurethane elastomer made from the following raw materials in the following weight percents:

[0042]

[0043] The specific preparation process is the same as that of Example 1, the difference is that the temperature of the reactor A is 95°C, the temperature of the reactor B is 55°C, and the temperature of the reactor C is 50°C; the A component and 1 / 2 of the B group Add in the first zone of the screw for pre-polymerization and blending. Then add component C and 1 / 2 of component B in the fifth zone of the screw; the temperature of the twin-screw extruder is 210° C., and the screw speed is 190 rpm.

Embodiment 3

[0045] An intrinsically antistatic thermoplastic polyurethane elastomer made from the following raw materials in the following weight percents:

[0046]

[0047] The specific preparation process is the same as in Example 1, the difference is that: the temperature of the reactor A is 100°C, the temperature of the reactor B is 40°C, and the temperature of the reactor C is 60°C; the A component and 1 / 2 of the B group Add in the first zone of the screw for pre-polymerization and blending. Then add component C and 1 / 2 component B in the fifth zone of the screw; the temperature of the twin-screw extruder is 205°C, and the screw speed is 200rmp.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com