Detection system applied to aerospace fluid active drag reduction experiment

A detection system and aerospace technology, applied in the aerospace field, can solve the problems of low detection efficiency, low detection accuracy, poor feedback, etc., and achieve the effects of accurate and reliable detection data, more detection data, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

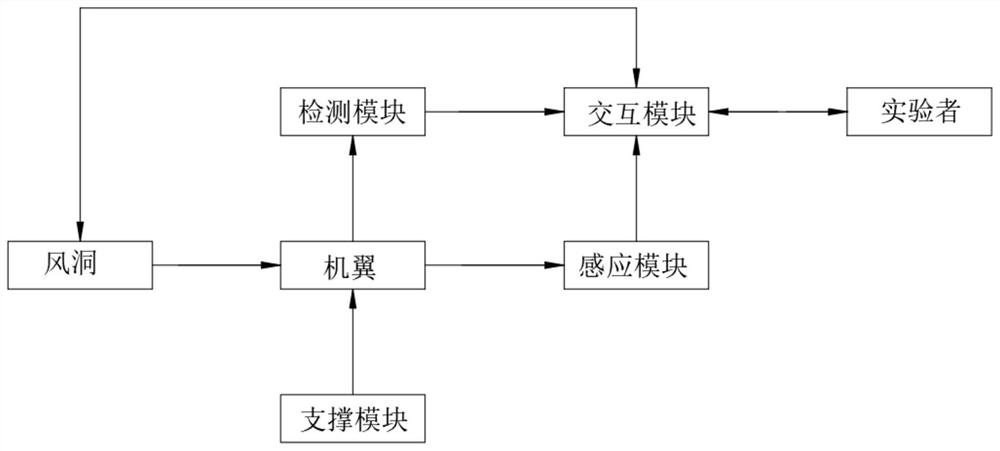

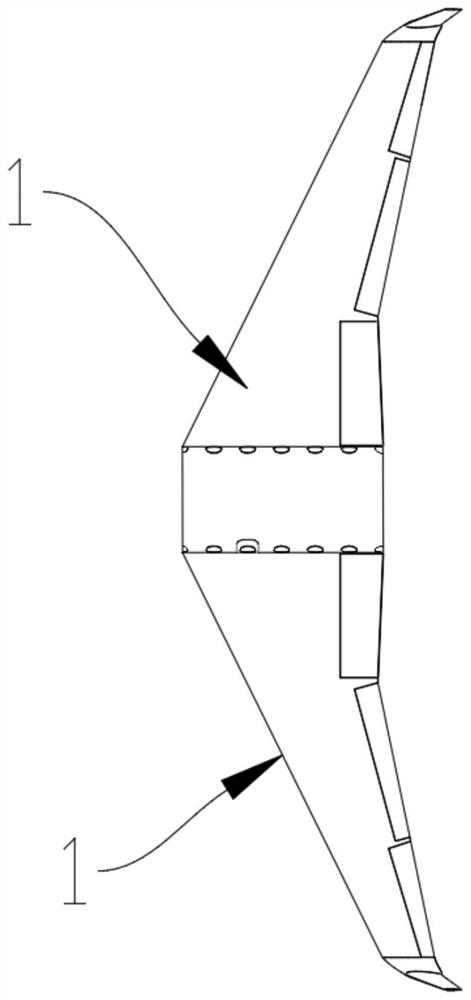

[0053] according to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 As shown, this embodiment provides a detection system applied to an active drag reduction experiment of aerospace fluids, including a wind tunnel, a wing, a detection module, and an induction module,

[0054] The detection module is used to detect the fluid on both sides of the wing to detect fluid velocity data on both sides of the wing;

[0055] The sensing module is used for sensing the deformation of the airfoil to analyze the drag reduction capability of the airfoil;

[0056] The detection module and the sensing module are arranged on the wing to detect the amplitude and fluid data of the wing;

[0057] The detection module includes a detection unit and a sampling unit, the detection unit is used to detect the fluid velocity on both sides of the airfoil; the sampling unit is used to detect the transformation amplitude of the airfoil;

[0058] The detection system fur...

Embodiment 2

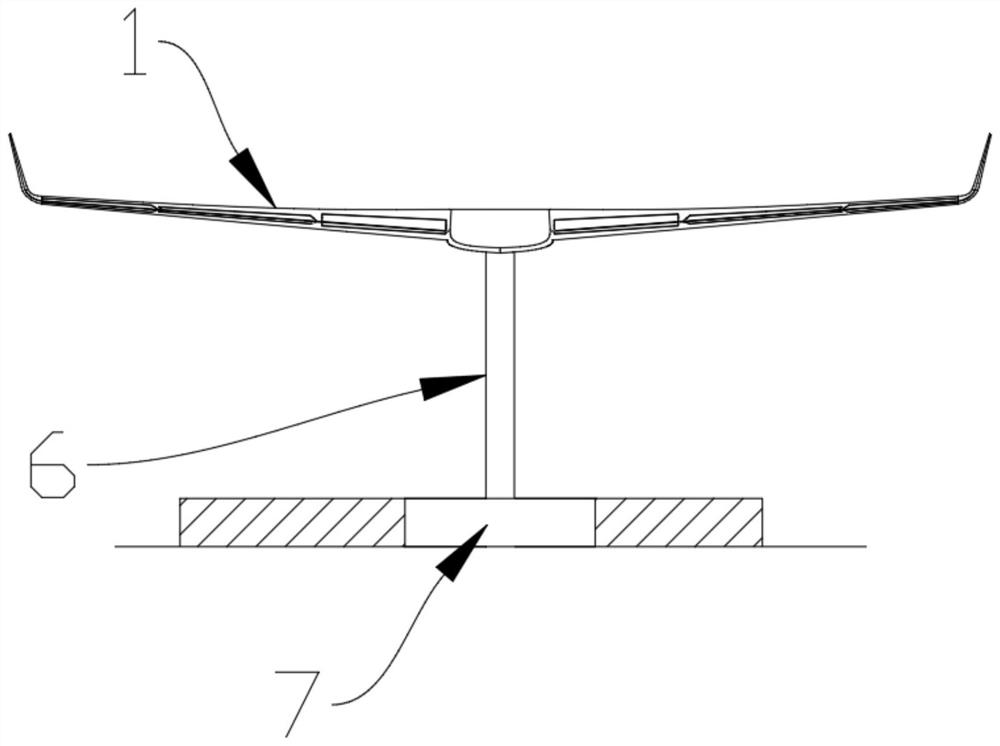

[0113] This embodiment should be understood as including at least all the features of any one of the foregoing embodiments, and further improved on the basis thereof, according to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 As shown, the support detection unit also includes a strain gauge sensor, a microprocessor and a feedback device, and the feedback device is used to feed back the processing result of the microprocessor to the interaction module; the microprocessors respectively control connection with the strain gauge sensor and feedback device;

[0114] The strain sensor is arranged on the rod body of the support rod, wherein the lateral strain force and the longitudinal strain of the support rod are detected;

[0115] The microprocessor obtains the rising strain k of the wing lift force to the support rod in one cycle, and the strain index G(k) generated by the support rod is calculated according to the following formula:

[0116...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com