Sewage treatment method and treatment system

A technology of sewage treatment system and sewage treatment method, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, centrifugal separation water/sewage treatment, etc. Water volume and effluent quality, limited application scenarios, etc., to achieve the effect of reducing sludge production, enhancing coagulation effect, and increasing application scenarios

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

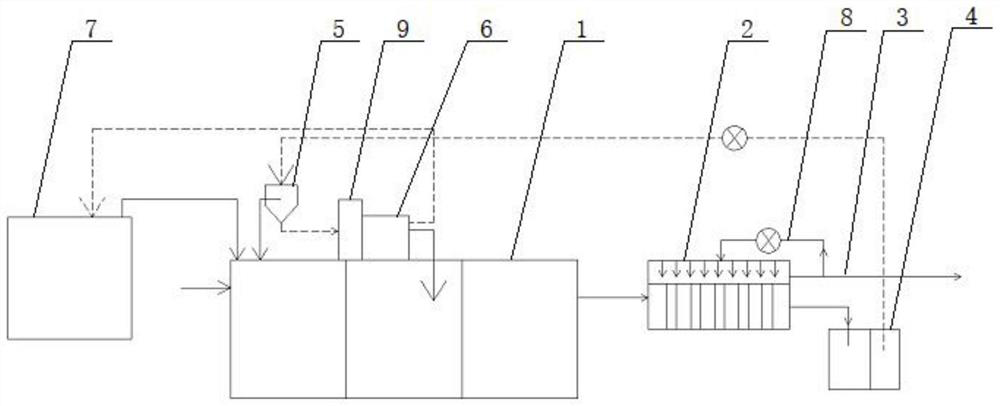

[0039]In this embodiment, the water body to be treated is a typical river channel, and the influent parameters mainly include total phosphorus (TP) and suspended solids (SS). The designed influent water quality is 5000 cubic meters per day, and the designed influent water quality is TP≤4mg / L, SS≤200mg / L; the designed effluent water quality index is required to meet the Class A standard of TP≤0.5mg / L, SS≤10mg / L . The sewage treatment system is used for treatment. The specific processing method is as follows:

[0040] After the raw water (sewage to be treated) enters the coagulation reaction tank 1, add magnetic powder, coagulant, flocculant and other chemicals into the coagulation reaction tank 1, so that the pollutants in the raw water form flocs with magnetic powder as the core , and flow into the solid-liquid separation device 2 with the overflow port of the coagulation reaction tank 1 (the solid-liquid separation device 2 selects a magnetic microfilter containing a magnet...

Embodiment 2

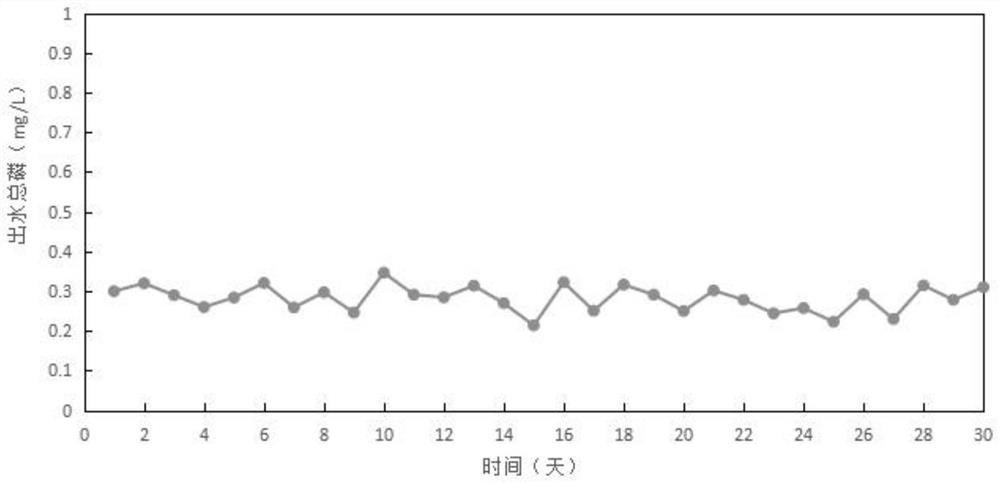

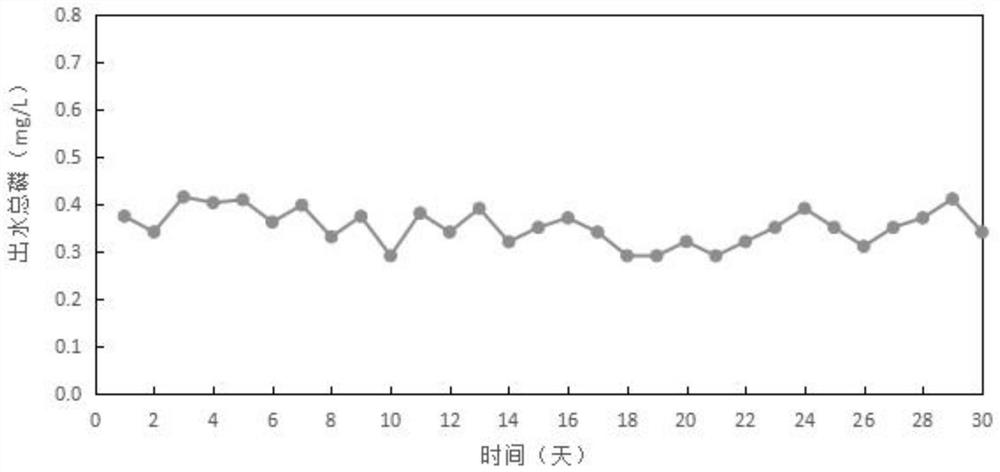

[0047] This embodiment is the same as embodiment 1 in terms of water quality and quantity and the use of a treatment system. For this treatment system, long-term monitoring of the concentration of suspended solids in the effluent of the system is carried out, and the monitoring results are as follows: Figure 4 shown:

Embodiment 3

[0052] This example is the same as Example 1 in terms of water quality and water quantity and the use of the treatment system. Since the construction method of each structure is changed, the overall height difference of the system is only about 4 meters, so there is no need for elevated or buried treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com