Fiber-reinforced self-curing silicone rubber and preparation method thereof

A fiber-reinforced, self-curing technology, applied in the field of non-metallic functional materials, can solve the problems of poor tensile strength and tear strength of self-curing silicone rubber, and achieve good flame retardancy, strong acid and alkali resistance, and improved mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] A second aspect of the embodiments of the present application provides a method for preparing fiber-reinforced self-curing silicone rubber, comprising the following steps:

[0047] S01. Provide each component according to fiber-reinforced self-curing silicone rubber;

[0048] S02. carry out a first mixing process with liquid silicone rubber, fibers, fillers and colorants to obtain a first mixed material;

[0049] S03. The crosslinking agent, the coupling agent, the aging agent, the catalyst and the first mixed material are subjected to a second mixing treatment, and extrusion molding is performed to obtain a fiber-reinforced self-curing silicone rubber.

[0050] The second aspect of the present application provides a method for preparing fiber-reinforced self-curing silicone rubber, the preparation method is divided into two steps, the liquid silicone rubber, fibers, fillers and colorants are respectively subjected to a first mixing treatment to obtain a first mixed mat...

Embodiment 1

[0059] Fiber-reinforced self-curing silicone rubber and preparation method thereof

[0060] Fiber-reinforced self-curing silicone rubber

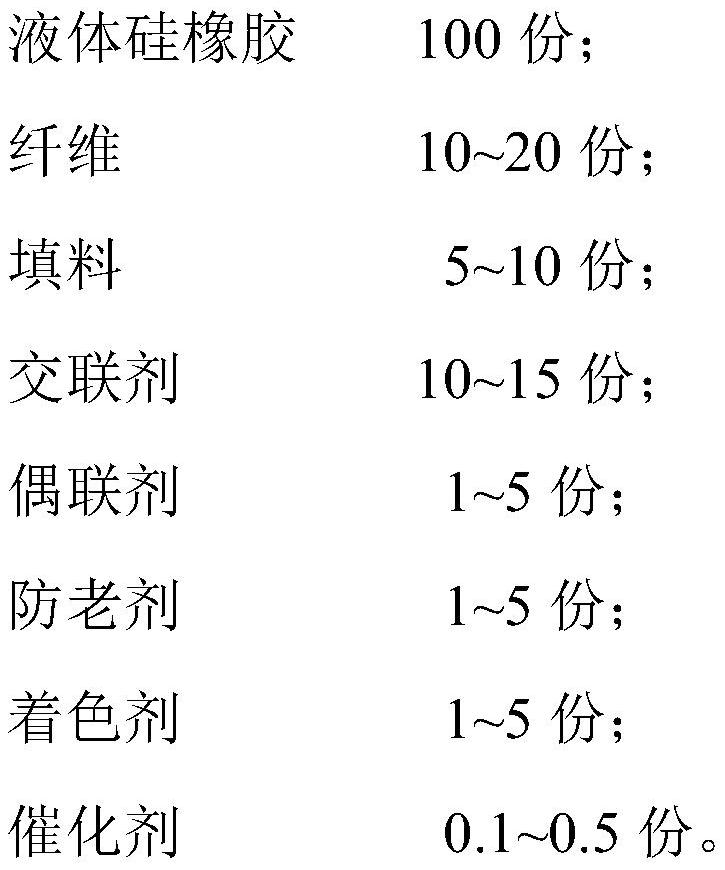

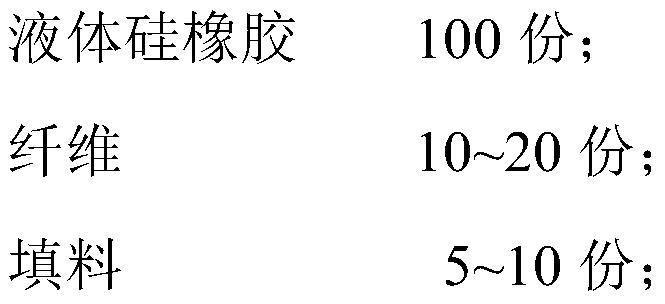

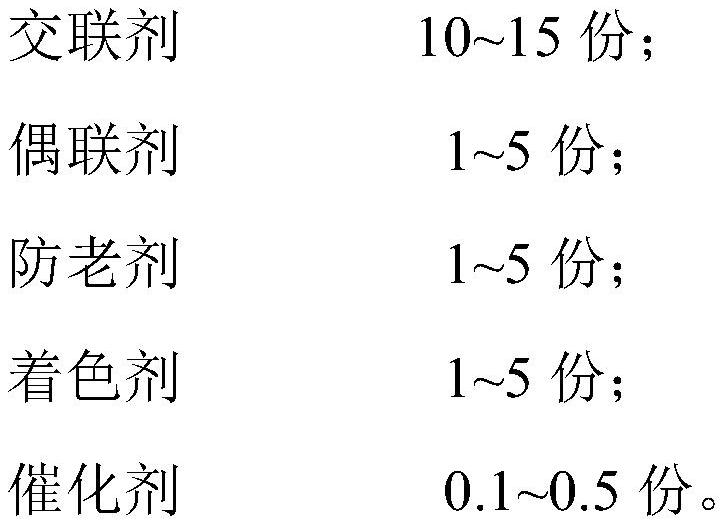

[0061] It includes the following components in the following parts by weight:

[0062]

[0063] Among them, the liquid silicone rubber is selected from α,ω-dihydroxy polydimethylsiloxane with a viscosity of 80000mPa·s; the fiber is selected from basalt fiber, the filler is selected from hydrophobic fumed silica, and the cross-linking agent is selected from methyl Tributyl ketoximinosilane, coupling agent selected from γ-aminopropyltriethoxysilane, antioxidant selected from N-phenyl-2-naphthylamine, colorant selected from pigment carbon black, catalyst selected from dilaurin Dibutyltin acid.

[0064] Preparation method of fiber-reinforced self-curing silicone rubber

[0065] The fiber-reinforced self-curing silicone rubber provided according to Example 1 provides each component;

[0066] Put liquid silicone rubber, fibers, fillers ...

Embodiment 2

[0070] The production method of the fiber-reinforced self-curing silicone rubber in Example 2 is exactly the same as that in Example 1, except that the amount of basalt fiber in Example 2 is 15 parts, and the proportions of other components are exactly the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com