Silicon carbide crystal ingot growth device and method

A growth device and silicon carbide technology, which is applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of uneven doping of semi-insulating silicon carbide crystal ingots, and improve quality, quality, and uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

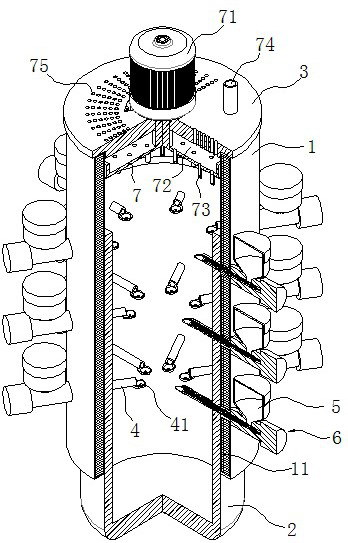

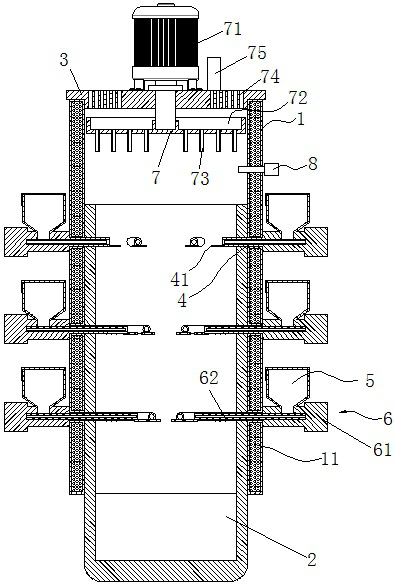

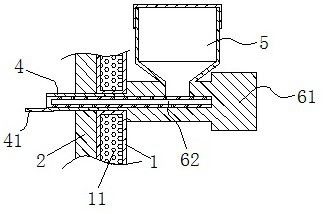

Image

Examples

Embodiment 2

[0043] refer to Figure 1-2 And 5, as another preferred embodiment of the present invention, the difference from Embodiment 1 is that a plurality of cooling pipes 73 are evenly distributed at the bottom of the silicon carbide ingot growth plate 7, and the cooling pipes 73 are communicated with the cooling grooves 72, The cooling pipe 73 can increase the cooling area of the silicon carbide crystal ingot growth plate 7 , so that the doped silicon carbide gas is easier to recrystallize and grow into a semi-insulating silicon carbide crystal ingot.

[0044] In order to further illustrate, the present invention also provides a method for growing a silicon carbide ingot, which is used in a silicon carbide ingot growing device to grow a silicon carbide ingot by means of synchronous sublimation and three-dimensional distribution mixing between the silicon carbide and the dopant. , the specific steps include:

[0045] Step 1. According to the doping ratio of the silicon carbide ingo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com