Detection method and system for steel surface coating

A surface coating and detection system technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of inability to quickly determine the position and size of steel surface coatings, distinguish coatings, and inaccurate detection results, etc., to achieve rapid determination , effective representation, and high signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

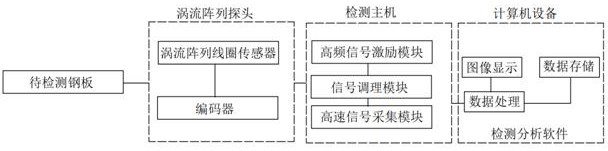

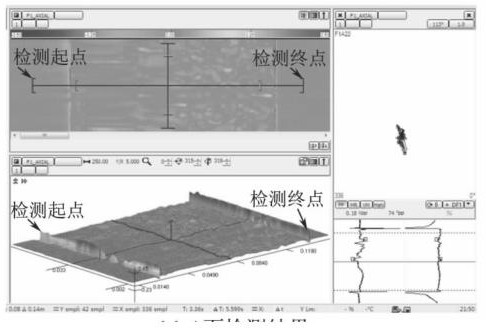

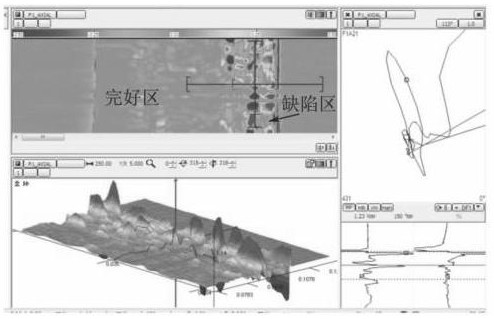

[0022] see figure 1 , In the embodiment of the present invention, a method and system for detecting a steel surface coating, including an eddy current array probe, a detection host and computer equipment, the eddy current array probe is composed of an eddy current array coil sensor and an encoder. The host includes a high-frequency signal excitation module, a signal conditioning module and a high-speed signal acquisition module, and the computer equipment is completed by the detection and analysis software to collect data for data processing, data storage and image display. The eddy current array probe is arranged in an array pattern by eddy current array coil sensors arranged at vertical intervals in sequence.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com