Aircraft component frame beam gap design method, device and equipment and storage medium

A technology of aircraft components and design methods, applied in computer-aided design, design optimization/simulation, calculation, etc., can solve problems such as low efficiency of design methods, achieve the effects of omitting repetitive work, meeting product quality requirements, and improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

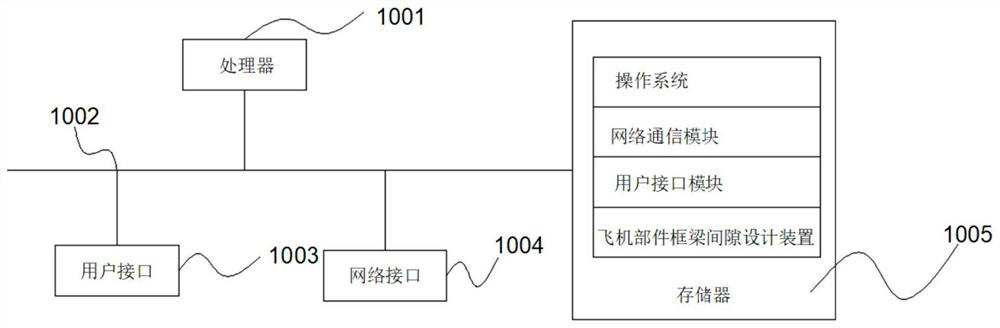

[0052] This embodiment, as a basic embodiment of the present invention, refers to figure 1 , figure 1 This is a schematic structural diagram of an electronic device of the hardware operating environment involved in the solution of the embodiment of the present application.

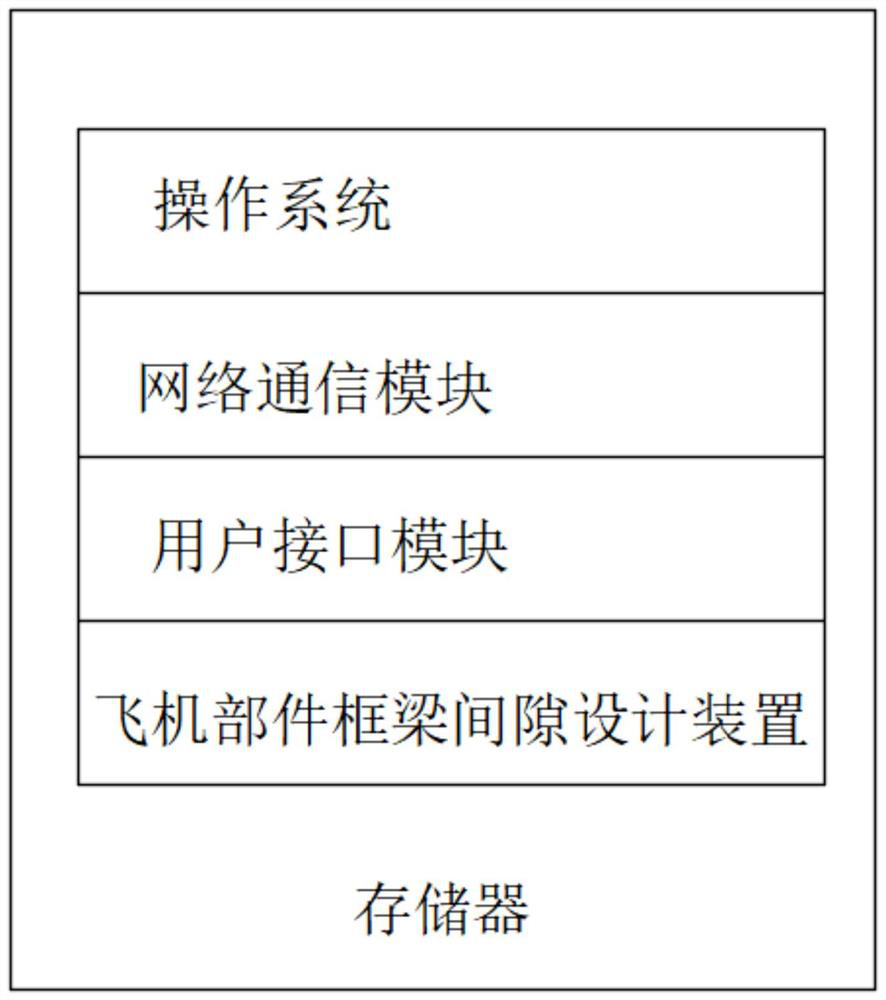

[0053] like figure 1 As shown, the production equipment may include: a processor 1001 , such as a central processing unit (Central Processing Unit, CPU), a communication bus 1002 , a user interface 1003 , a network interface 1004 , and a memory 1005 . Among them, the communication bus 1002 is used to realize the connection and communication between these components. The user interface 1003 may include a display screen (Display), an input unit such as a keyboard (Keyboard), and the optional user interface 1003 may also include a standard wired interface and a wireless interface. Optionally, the network interface 1004 may include a standard wired interface and a wireless interface (eg, a wireless fidelity...

Embodiment approach 2

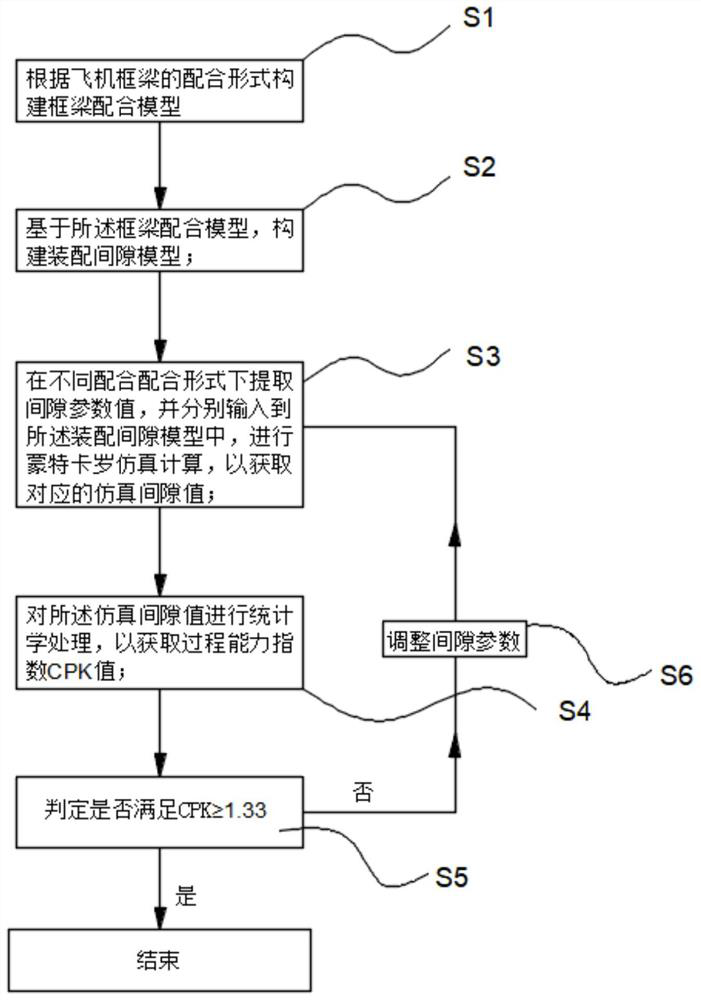

[0101] This embodiment, as a basic embodiment of the present invention, discloses a method for designing a frame beam gap of an aircraft component. In this embodiment, a front and a rear frame are connected by a positioning beam for cooperation. In the above matching relationship, The end faces on both sides of the beam and the frame web are positioned through the positioning holes, and a gap is formed between the beam end and the frame web. In this embodiment, the structural assembly gap compensation threshold is 0.2mm, that is, USL=0.2, LSL=0;

[0102] S1. Build a frame-beam fitting model according to the fitting form of the aircraft frame-beam;

[0103] Draw the structure diagram of the frame and beam according to the actual structure of the frame beam, and draw the assembly diagram of the frame and the beam according to the actual assembly relationship. The assembly diagram is the frame-beam matching model. , the frame-beam fitting model is as follows Figure 5 shown;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com