Lithium metal battery negative electrode and preparation method thereof

A lithium metal battery and negative electrode technology, which is applied in the field of lithium metal battery negative electrode and its preparation, can solve the problems of hindering the practical application of lithium metal battery, uneven lithium deposition, capacity loss, etc., and achieves reduction of nucleation overpotential and affinity The effect of lifting, polarization improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

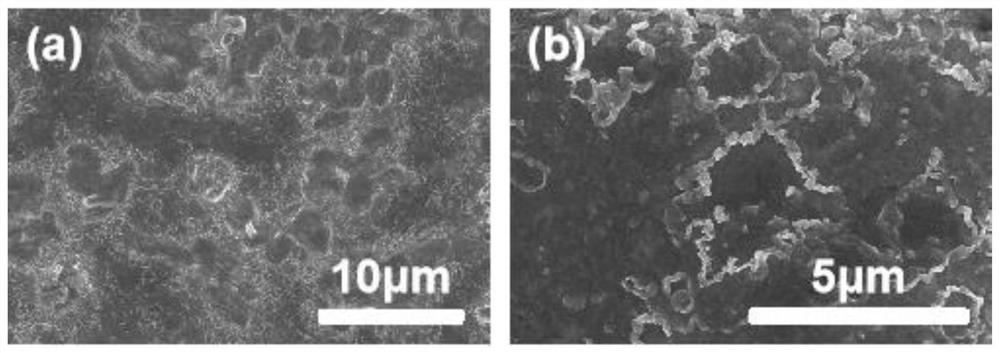

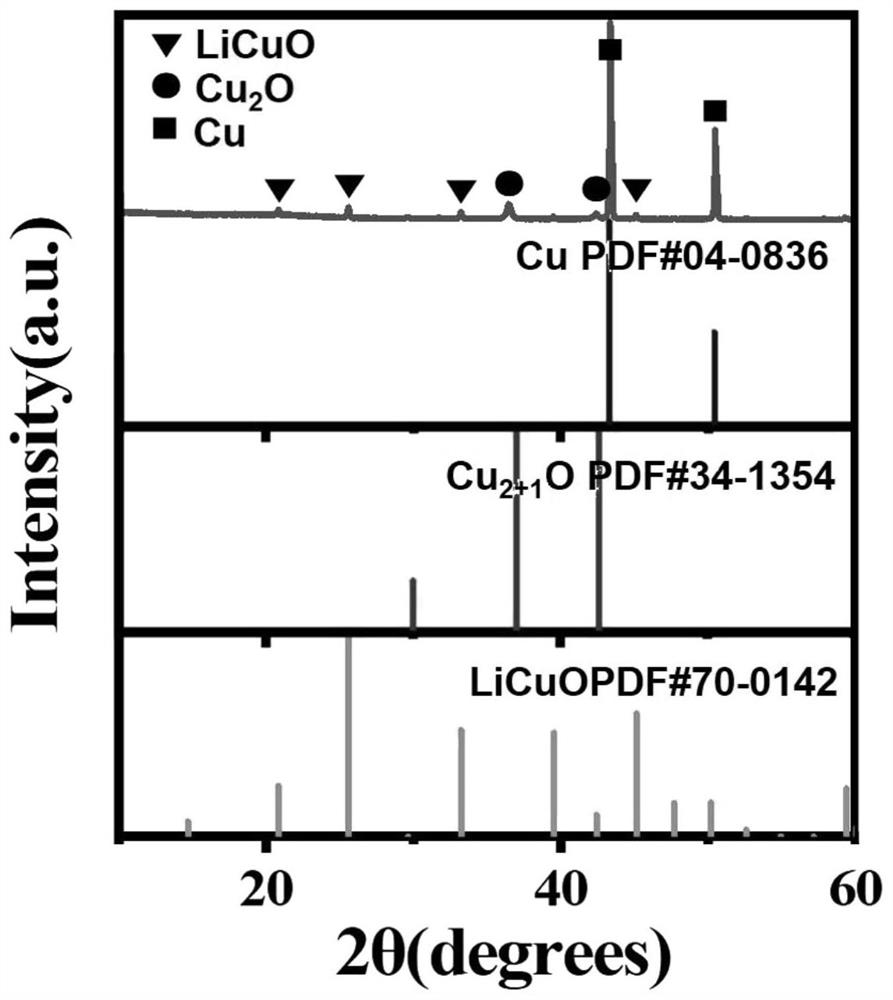

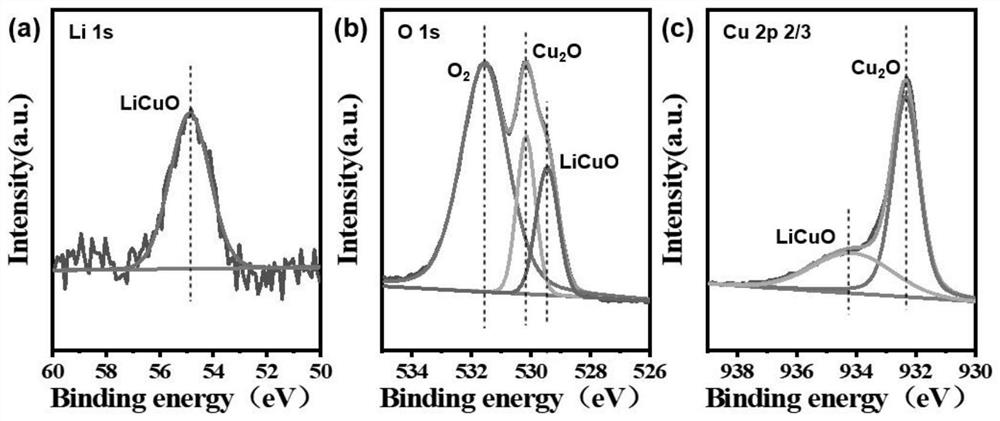

[0025] The preparation steps of a lithium metal battery negative electrode are as follows:

[0026] (1) Measure a certain amount of concentrated hydrochloric acid into distilled water and dilute to 1mol / L;

[0027] (2) Place the copper foil in diluted hydrochloric acid for cleaning to remove impurities and grease on the surface of the copper foil, and then repeatedly wash it with secondary water 3 times, then with anhydrous ethanol 3 times, and blow it with a hair dryer after cleaning. Dry;

[0028] (3) The copper foil obtained in step (2) is directly placed in a muffle furnace for heating treatment, and the temperature is raised to 250°C at a heating rate of 2°C / min, and the holding time is 2h;

[0029] (4) Weigh 20 mg of lithium oxide as the lithium source and place it in the porcelain boat;

[0030] (5) Cut the oxidized copper foil to 3 cm*6 cm and place it on the porcelain boat and fix it;

[0031] (6) Put the porcelain boat in step (5) in a high-temperature reaction fu...

Embodiment 2

[0033] A lithium metal battery negative electrode, wherein the negative electrode is a layer of LiCuO lithiophilic layer decorated on the surface of a copper foil current collector.

[0034] A preparation step for a negative electrode of a lithium metal battery is as follows:

[0035] (1) Measure a certain amount of concentrated hydrochloric acid into distilled water and dilute to 1mol / L;

[0036] (2) Place the copper foil in diluted hydrochloric acid for cleaning to remove impurities and grease on the surface of the copper foil, and then repeatedly wash it with secondary water 3 times, then with anhydrous ethanol 3 times, and blow it with a hair dryer after cleaning. Dry;

[0037] (3) The copper foil obtained in step (2) is directly placed in a muffle furnace for heating treatment, and the temperature is raised to 200°C at a heating rate of 2°C / min, and the holding time is 3h;

[0038] (4) Weigh 50 mg of lithium hydroxide as the lithium source and place it in the porcelain ...

Embodiment 3

[0042] A lithium metal battery negative electrode, wherein the negative electrode is a layer of LiCuO lithiophilic layer decorated on the surface of a copper foil current collector.

[0043] A preparation step for a negative electrode of a lithium metal battery is as follows:

[0044] (1) Measure a certain amount of concentrated hydrochloric acid into distilled water and dilute to 1mol / L;

[0045] (2) Place the copper foil in diluted hydrochloric acid for cleaning to remove impurities and grease on the surface of the copper foil, and then repeatedly wash it with secondary water 3 times, then with anhydrous ethanol 3 times, and blow it with a hair dryer after cleaning. Dry;

[0046] (3) The copper foil obtained in step (2) is directly placed in a muffle furnace for heating treatment, and the temperature is raised to 300°C at a heating rate of 2°C / min, and the holding time is 1h;

[0047] (4) Weigh 100 mg of lithium carbonate as the lithium source and place it in the porcelain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com