Resourceful processing treatment method for mangoes

A treatment method and resource-based technology, applied in the field of mango resource-based processing, can solve problems affecting processing capacity, low efficiency, and long enzymatic hydrolysis time, and achieve the benefits of enzymatic hydrolysis, fast enzymatic hydrolysis, and improved enzyme activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A mango resource processing method, comprising the following steps:

[0028] S1: After ripening, crushing and beating the mango raw materials, separate to obtain a mixture of mango juice pulp, peel and pit; then separate the peel and pit mixture to obtain mango peel; finely filter to separate the crude fiber in the mango juice pulp, and then the mango juice pulp Homogenize, reserve;

[0029] S2: Mix mango peel, crude fiber and water at a ratio of material to liquid of 1:1, crush them into pulp, add 0.001% pectinase by weight of the pulp, and xylanase at 0.03% by weight of the pulp, and pass through the volume concentration The ethylene of 0.8‰ was enzymatically hydrolyzed under ultrasonic conditions, the ultrasonic power was 250W, the ultrasonic time was 2s for 1s, the enzymolysis time was 15min, the temperature was 45℃, and the pH value was 4.0; the peel pulp after enzymolysis was at 95℃ The enzyme is inactivated, and the aroma is flashed in a vacuum to obtain a mango...

Embodiment 2

[0032] A mango resource processing method, comprising the following steps:

[0033] S1: After ripening, crushing and beating the mango raw materials, separate to obtain a mixture of mango juice pulp, peel and pit; then separate the peel and pit mixture to obtain mango peel; finely filter to separate the crude fiber in the mango juice pulp, and then the mango juice pulp Homogenize, reserve;

[0034] S2: Mix mango peel, crude fiber and water at a ratio of material to liquid of 1:2, crush into pulp, add pectinase with a weight of 0.002% of the slurry, and xylanase with a weight of 0.02% of the slurry, and pass through the volume concentration The ethylene of 0.9‰ was enzymatically hydrolyzed under ultrasonic conditions, the ultrasonic power was 300W, each ultrasonic wave was 2s for 1s, the enzymolysis time was 18min, the temperature was 55℃, and the pH value was 4.5; the peel pulp after enzymolysis was at 98℃ The enzyme is inactivated, and the aroma is flashed in a vacuum to obt...

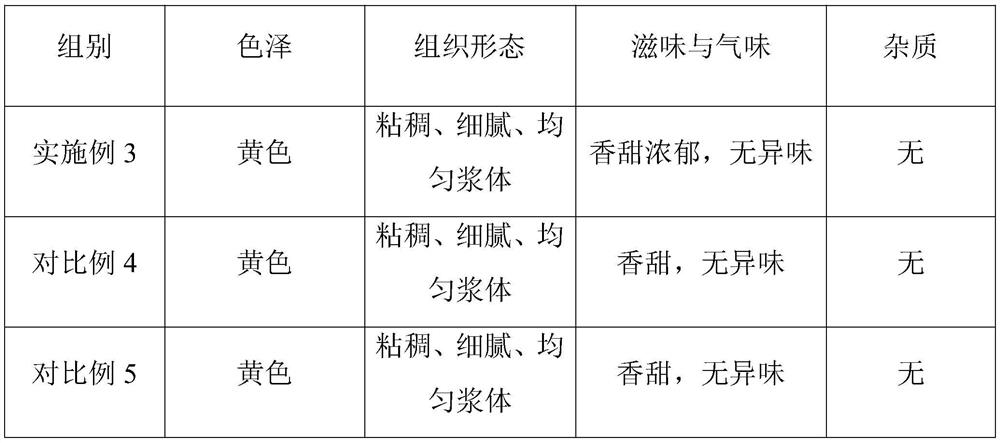

Embodiment 3

[0038] A mango resource processing method, comprising the following steps:

[0039] S1: After the mango raw materials are ripened, crushed and beaten, the mixture of mango juice pulp, peel and core is obtained by separation; then the mixture of peel and core is separated to obtain mango skin; the crude fiber in the mango juice pulp is separated by fine filtration, and then the mango juice pulp is obtained. Homogenize, reserve;

[0040] S2: Mix mango peel, crude fiber and water at a ratio of material to liquid of 1:2, crush into pulp, add pectinase with a weight of 0.004% of the slurry, and xylanase with a weight of 0.014% of the slurry, and pass through the volume concentration For ethylene of 0.9‰, enzymolysis was carried out under ultrasonic conditions, the ultrasonic power was 350W, the sonication was stopped for 1s every 2s, the enzymolysis time was 20min, the temperature was 50℃, and the pH value was 4.5; the peel pulp after enzymolysis was at 95℃ The enzyme is inactivat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com