Optical precision measurement developer spraying device

A spraying device, optical precision technology, applied in spraying devices, manufacturing tools, manipulators, etc., can solve the problems of poor consistency of coating thickness, low spraying efficiency, poor consistency of powder layer thickness on the surface of parts, etc., to ensure consistency and automation The effect of spraying and improving the measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

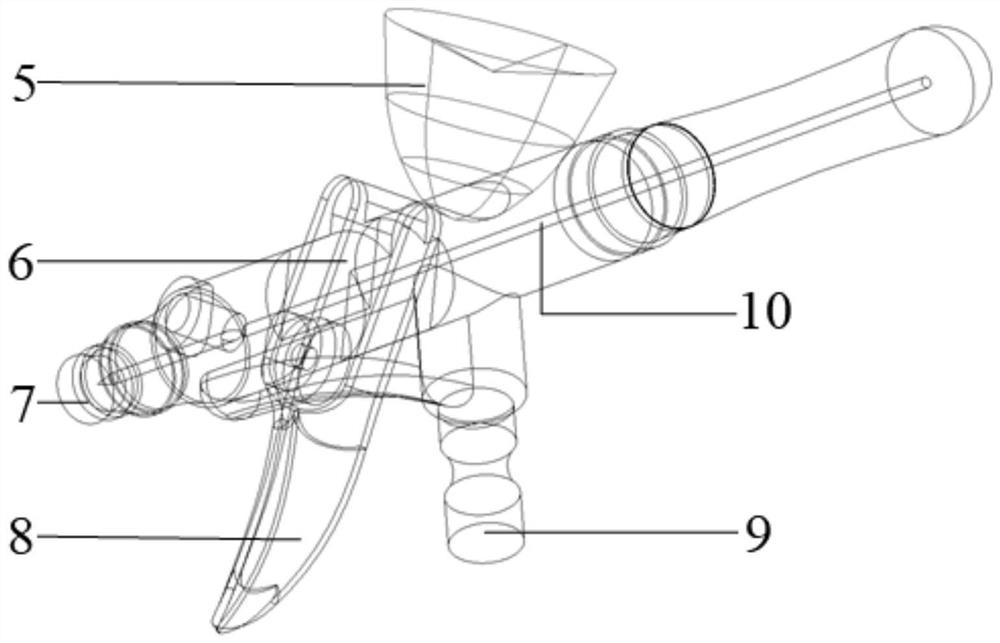

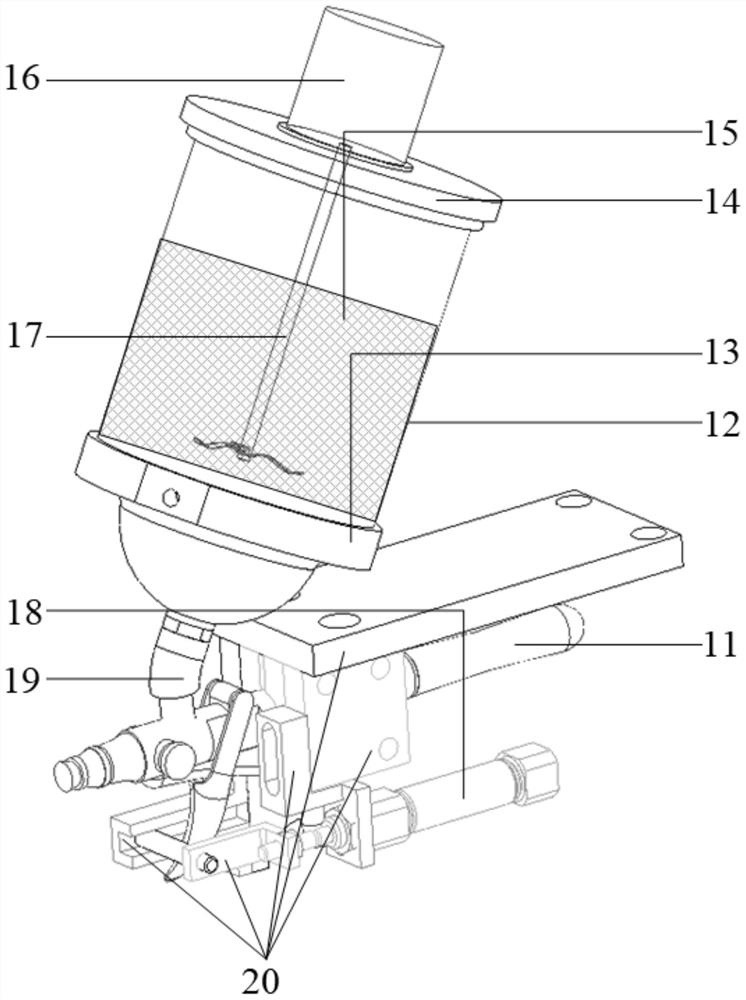

[0043] This embodiment provides an optical precision measurement imaging agent spraying device, which can realize long-term, uniform, fast and automatic spraying of optical imaging agent, which is used for the pretreatment of optical precision measurement of highly reflective parts, which is beneficial to improve the high reflection rate. Measurement accuracy of point cloud coordinates for optical 3D measurement of parts.

[0044] like image 3 and Figure 4 As shown, the developer spraying device includes: an atomizing mechanism, a transparent liquid storage tank and an automatic stirrer I17; wherein, the transparent liquid storage tank is used to store the liquid paint 15, and its internal volume is not less than 50ml, which can meet the needs of large-sized parts The long-term spraying is composed of the tank body 12, the upper cover 14 and the lower cover 13, and the lower cover 13 and the upper cover 14 are respectively screwed on the two ends of the tank body 12, and th...

Embodiment 2

[0055] On the basis of Example 1, because in engineering applications, large-scale parts or parts such as the shape of the whole vehicle are sprayed in batches, the liquid storage tank with a volume of 500ml still cannot meet the requirements of long-term spraying operations; if the volume of the liquid storage tank is increased again , cannot meet the requirements of operational flexibility and structural stability; therefore, the present embodiment adds a large-capacity paint storage tank 25, and communicates it with the transparent liquid storage tank in the developer spraying device through the paint conduit 24;

[0056] like Figure 5 As shown, in theory, the paint large-capacity liquid storage tank 25 can be designed to meet any volume of actual needs, taking the developer spraying device 23 based on the automatic spray gun as an example, the volume of the paint large-capacity liquid storage tank 25 is not less than 2L; The paint large-capacity liquid storage tank 25 is ...

Embodiment 3

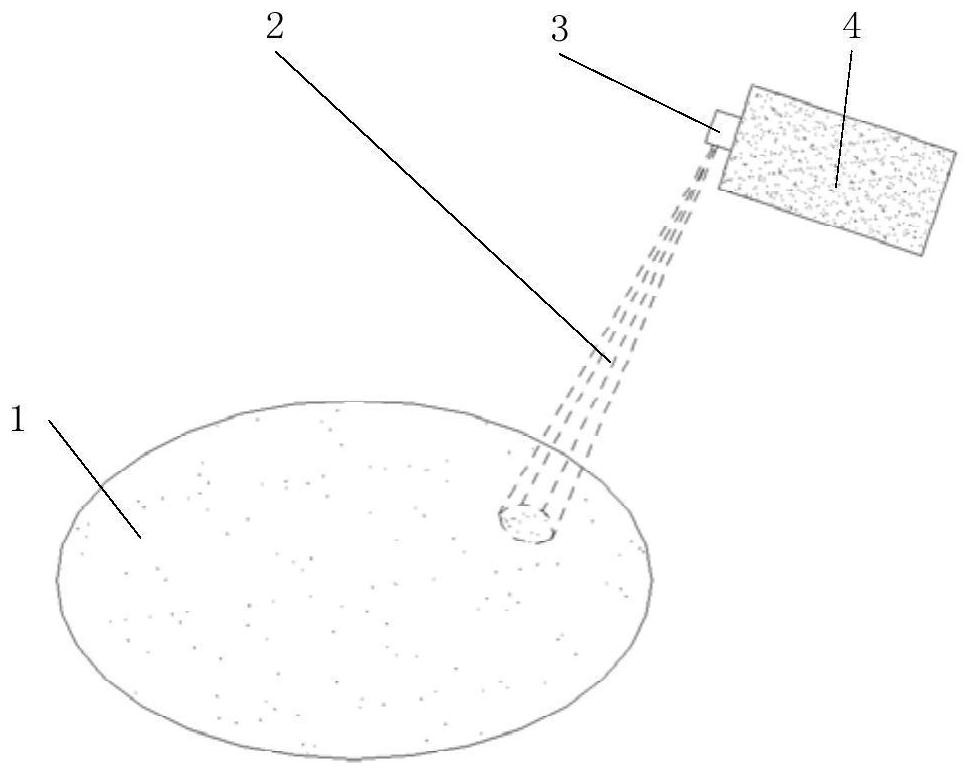

[0061] On the basis of Example 1 and Example 2, in order to greatly improve the spraying efficiency and reduce the labor intensity of operators, the developer spraying device is integrated into the end of the robot 34 through the robot connecting flange 31, combined with the external turntable and linear guide rails. Equal displacement mechanism constitutes an automatic spraying system. The automatic spraying system is placed in the spraying (room) room, and the gas filter device is added to realize the automatic spraying of parts in the production workshop; on this basis, through reasonable planning of the robot 34 spraying paths, you can control the relative position and attitude of the nozzle of the atomization mechanism (airbrush 11 or automatic spray gun 21) and the object to be measured 1, and use the closed-loop feedback control system of spraying parameters such as pressure and flow to realize large-size parts or batches. Precision spraying of parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com