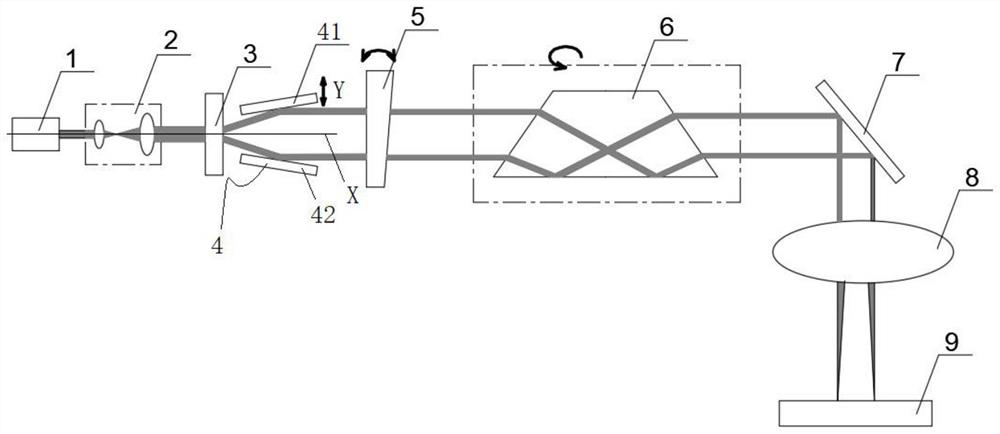

Carbon fiber composite material hole machining system and method based on laser double-beam rotary cutting

A hole processing method and composite material technology, applied in metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve the problems of complex structure, high precision requirements for installation and positioning, and unfavorable large-scale promotion, so as to improve the smoothness , The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] An ultraviolet nanosecond laser with a laser beam wavelength of 355 nm is selected, the laser beam spot size is about 30 μm, and the thickness of the carbon fiber composite material 9 is 3 mm.

[0062] Set the laser repetition frequency to 45kHz and the scanning speed to 1000mm / s;

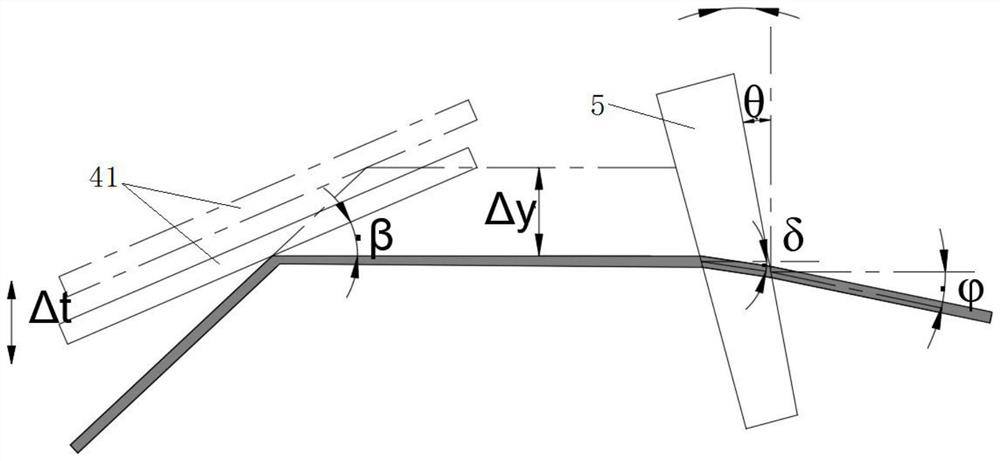

[0063] Adjust the position of the aperture adjustment unit 4 and the deflection angle of the angle adjuster 5 according to the focal length of the focusing lens 8 and the diameter of the hole, so that the laser beam can be perpendicular to the carbon fiber composite material 9;

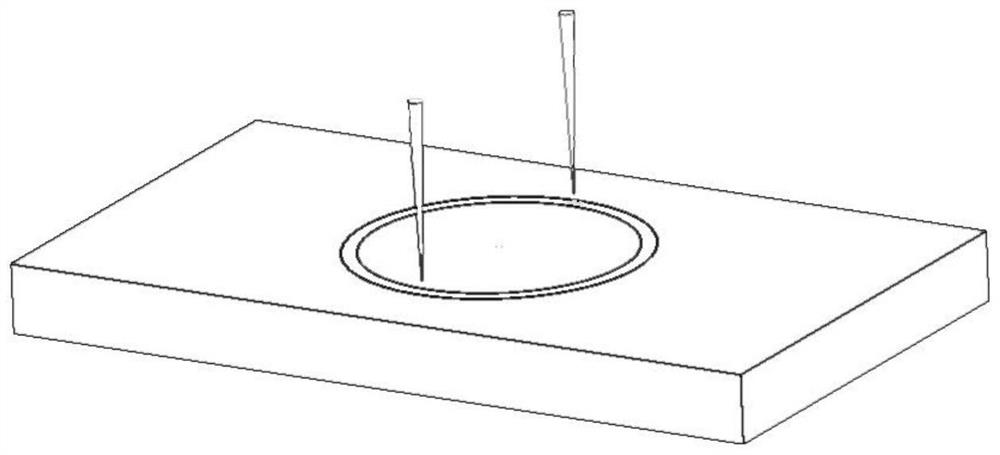

[0064] Turn on the laser 1, focus the laser beam on the surface of the carbon fiber composite material 9, and scan, and every 50 scans, the focusing lens 8 is moved down by 0.3mm to complete the layered cutting, until a non-tapered through hole (such as a diameter of 10mm) is formed. Figure 4 shown).

Embodiment 2

[0066] Adjust the position of the aperture adjustment unit 4 and the deflection angle of the angle adjuster 5 according to the hole taper requirements, wherein the counterclockwise rotation of the angle adjuster 5 can obtain a through hole with a positive taper (the diameter of the entrance of the hole is greater than the diameter of the exit) (ie Figure 5 shown), otherwise a hole with a negative taper is obtained, and other steps are the same as in Example 1, and will not be repeated here.

[0067] To sum up, the present invention has a simple structure design, does not require complex equipment and high control precision requirements, and can greatly improve the processing efficiency. Drilling has obvious advantages. Specifically, it can process through holes with zero taper or any taper on carbon fiber materials by adjusting the position of the aperture adjustment unit and the angle adjuster, and it is beneficial to improve the smoothness of the hole wall.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com