Manufacturing method of sabot system of ground simulation test for aircraft strength test

A technology of ground simulation and aircraft strength, applied in the field of aircraft testing, can solve problems such as difficulty in controlling the friction between the bullet and the magazine, the influence of the separation of the bullet and the magazine, and the installation of the bullet to the bottom of the magazine, etc., to achieve light weight and moderate tightness , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

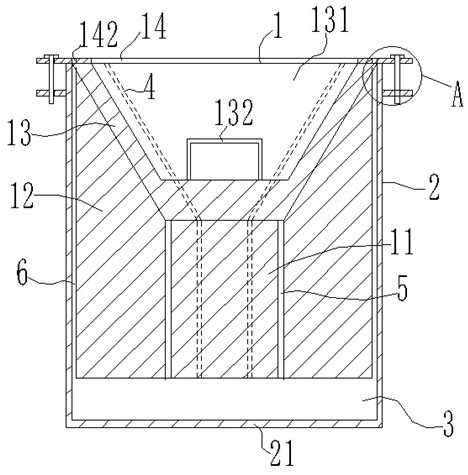

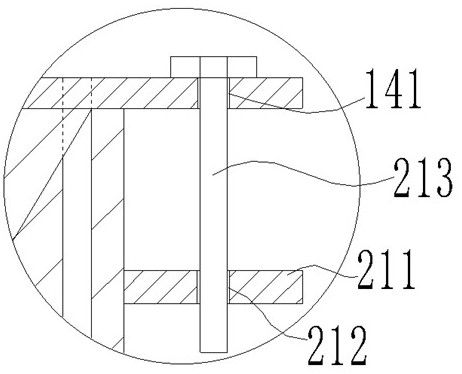

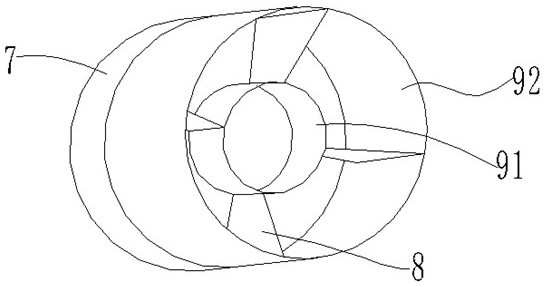

[0033] like Figure 4 As shown in the figure, a method for making a bomb carrier system for ground simulation test for aircraft strength test includes the following steps:

[0034] S1. Design the elastic mold:

[0035] According to the inner diameter of the air gun and the weight of the bird bomb, the ejector support structure is designed, and the ejection mold design drawing is drawn according to the ejection support structure. Combined with the ejection mold design drawing, 3D software is used to model each part of the ejection mold in 3D, and the parts of the ejector mold are obtained. 3D drawing and general assembly drawing of the elastic mold;

[0036] S2. Manufacture of elastic mold:

[0037] Carry out CAM tool path program design on the three-dimensional diagram of each part obtained in step S1 and import it into the CNC manufacturing process to manufacture each part, and then assemble according to the general assembly drawing of the spring support mold to obtain the ...

Embodiment 2

[0046] The difference from Example 1 is that:

[0047] In step S3, the stirring temperature is 50° C., the stirring speed is 120 r / min, and the stirring time is 5 min;

[0048] In step S4, the elastic support mold is put into the heat preservation device, and the heat preservation temperature is 30 ° C. After the upper mold 1 and the lower mold 2 are kept in the heat preservation device for 48 minutes, the upper mold 1 and the lower mold 2 are separated. The temperature in the insulation device is 30℃ for 30h;

[0049]The release agent is composed of the following components by weight: 1.9 parts of sorbitan monooleate SPAN-80, 2.5 parts of n-butanol, 3.0 parts of polystyrene PS, 2.0 parts of ethyl acetate, 0.8 parts of additives, 6.0 parts of ionized water;

[0050] The additive is composed of the following components by weight: 0.2 part of oxidizing agent, 0.3 part of reducing agent, 0.3 part of chain transfer agent;

[0051] The elastic support mold material is composed o...

Embodiment 3

[0053] The difference from Example 1 is that:

[0054] In step S3, the stirring temperature is 45° C., the stirring speed is 100 r / min, and the stirring time is 5 min;

[0055] In step S4, the elastic support mold is put into the heat preservation device, and the heat preservation temperature is 24 ° C. After the upper mold 1 and the lower mold 2 are kept in the heat preservation device for 50 minutes, the upper mold 1 and the lower mold 2 are separated. The placing temperature in the heat preservation device is 20℃ for 26h;

[0056] The release agent is composed of the following components by weight: 1.7 parts of sorbitan monooleate SPAN-80, 2.3 parts of n-butanol, 2.5 parts of polystyrene PS, 1.8 parts of ethyl acetate, 0.5 parts of additives, 5.8 parts of ionized water;

[0057] The additive is composed of the following components by weight: 0.15 part of oxidizing agent, 0.15 part of reducing agent, 0.2 part of chain transfer agent;

[0058] The elastic support mold mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com