Processes for preparing grafted copolymers

A graft copolymer, graft polymer technology, used in DVII's and lubricating oil compositions, to prepare a graft polymer for use as a dispersant viscosity index improver; In the field of branched polymers, it can solve the problems such as the limitation of extrusion method and the inability to obtain grafted products, and achieve the effect of reducing the tendency of polymerization and coupling side reactions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0178] equipment and materials

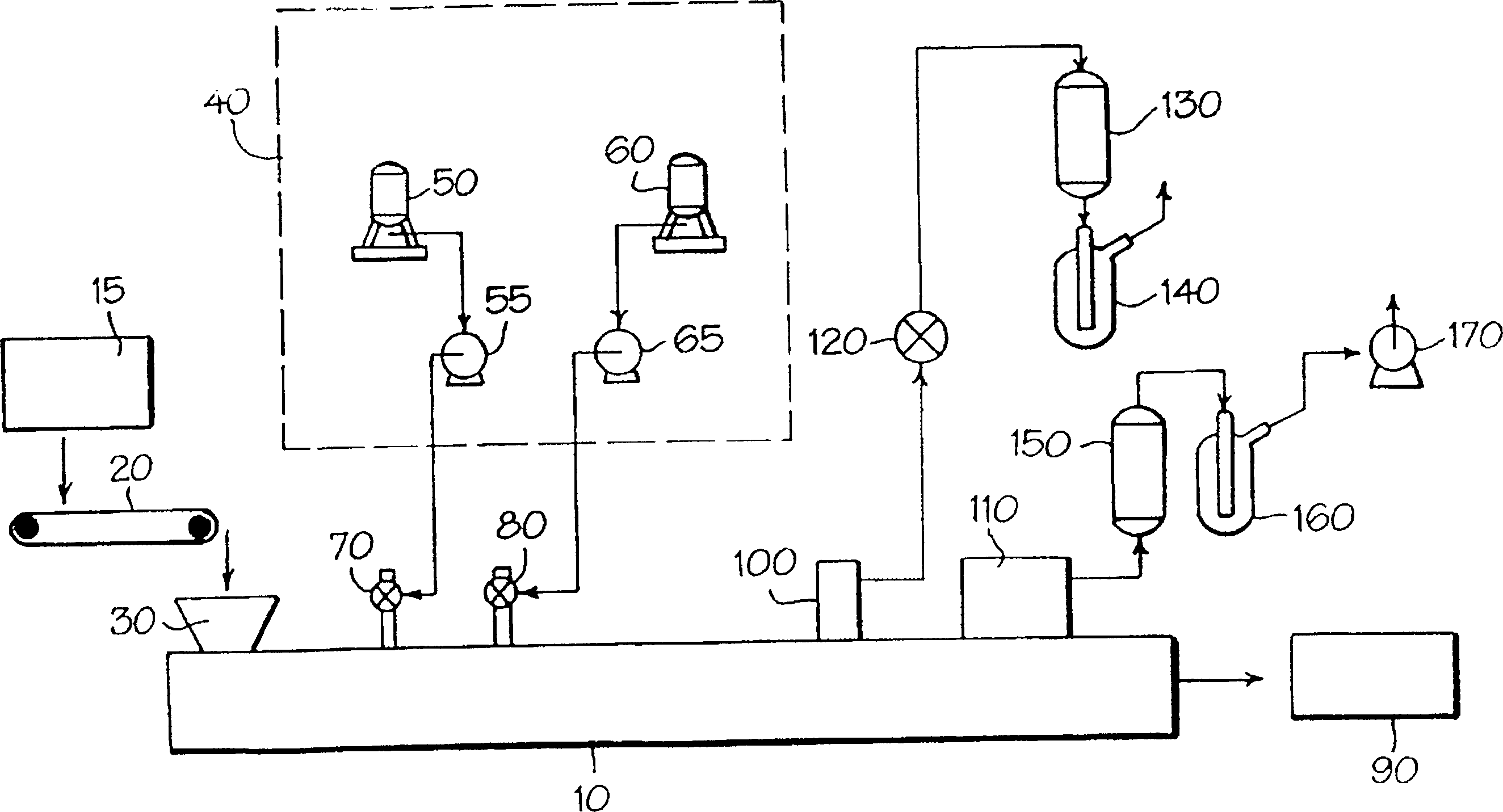

[0179] A schematic diagram of the overall flow is shown in the figure.

[0180] A. Reactor Extruder

[0181] A HT-2000-F11-M-21-523-E2" twin-screw extruder from Welding Engineers' Company was used. The extruder used up to 4 inlets for liquid additives in the axial direction. A 1.5 inch (3.8 cm) thick separation plate for instrumentation was provided, and five inlets were provided in barrel 3 and 4 more inlets in barrel 4. For the twin screw section The ratio of the overall length of the extruder to its diameter ("L / D") is said to be 57: 1. The extruder also has a 3:1 L / D single screw discharge section.

[0182] B. Extruder heating

[0183] The extruder was initially heated with two-zone hot oil. The first zone includes the second to fifth barrels, and the second zone is used to heat the sixth to ninth barrels. The feed barrel is cooled with process water, and the die head is electrically heated.

[0184] C. Feeding equipment

[0185] The...

example 3

[0229] Polyolefin CO-034

[0230] Polyolefin Feed Rate (lbs / hr) 35 (16kg / hr)

[0231] Monomer (% w / w: solvent) VIMA (50%: aqueous solution)

[0232] Monomer feed rate (lbs / hr, actual monomer) 0.38 (0.17kg / hr)

[0233] Initiator (% w / w: solvent) DTBP (20% naphtha solution)

[0234] Initiator feed rate (lbs / hr, actual initiator) 0.1 (0.045kg / hr)

[0235] Screw Speed (RPM) 90

[0236] Temperature distribution (℃) 185, 218, 206, 192, 201

[0237] Monomer on graft polymer (%) 1.46

[0238] ADT 8

example 4

[0240] Polyolefin CO-034

[0241] Polyolefin Feed Rate (lbs / hr) 35 (16kg / hr)

[0242] Monomer (% w / w: solvent) VIMA (25% aqueous solution)

[0243] Monomer feed rate (lbs / hr, actual monomer) 0.73 (0.33 kg / hr)

[0244] Initiator (% w / w: solvent) DTBP (20% P160N solution)

[0245] Initiator feed rate (lbs / hr, actual initiator) 0.2 (0.09kg / hr)

[0246] Screw Speed (RPM) 90

[0247] Temperature distribution (℃) 185, 220, 201, 187, 202

[0248] Monomer on the graft polymer (%) 1.63

[0249] ADT 16 / 8

PUM

| Property | Measurement | Unit |

|---|---|---|

| dispersity | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com