High-transparency hydrophobic self-cleaning MOFs coating and preparation method thereof

A high-transparency, self-cleaning technology, applied in the coating field, can solve the problems of easy-to-wear lubricants, low hysteresis angle, poor mechanical stability, etc., and achieve low refractive index, high light transmittance and good self-cleaning effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Immerse the glass substrate in a n-hexane solution containing 1% 3-aminopropyltriethoxysilane, soak it at 25°C for 2 hours, take out the glass substrate and rinse it with n-hexane, and dry it in a drying oven at 100°C for 1 hour;

[0025] (2) The glass substrate loaded with 3-aminopropyltriethoxysilane was immersed in a 100 mL N,N-dimethylformamide solution hydrothermal reaction kettle containing 5.95 g of tetrafluoroterephthalic acid for a closed reaction at 120 °C for 4 h, Then, it was immersed in 100 mL of N,N-dimethylformamide solution containing 5.83 g of zirconium chloride and reacted at 120° C. for 20 min, ending one cycle. The same procedure was cycled twice, and 2-layer MOFs coatings were prepared on glass substrates.

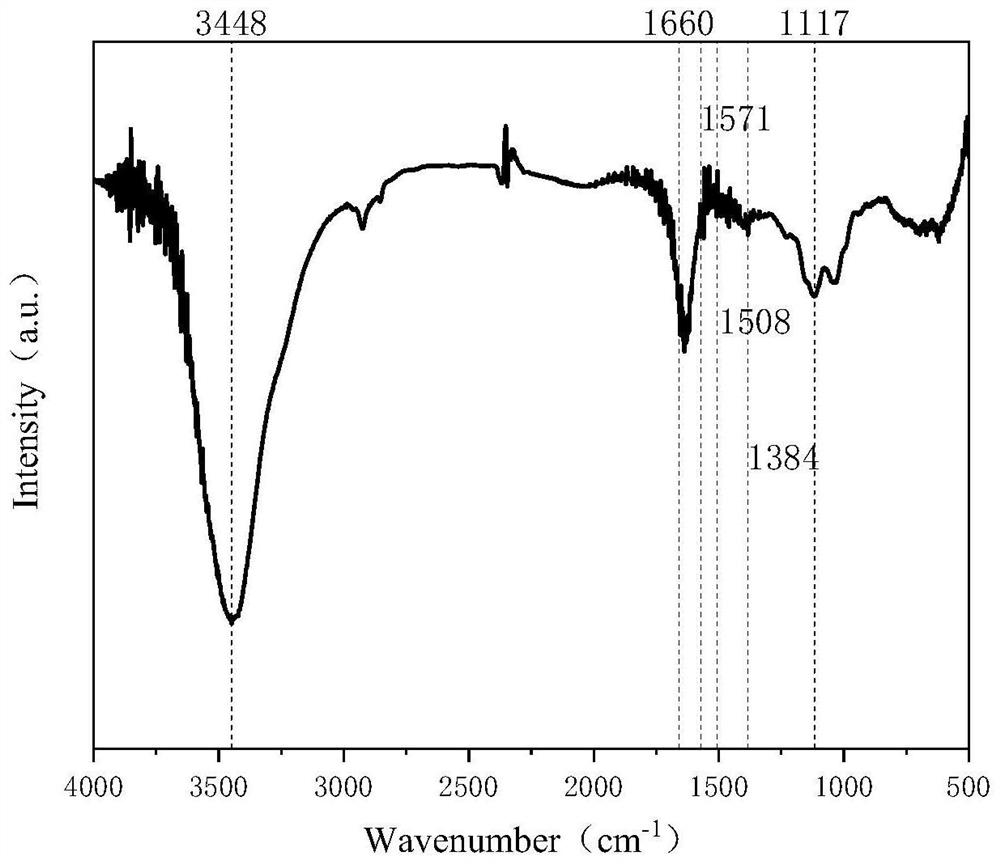

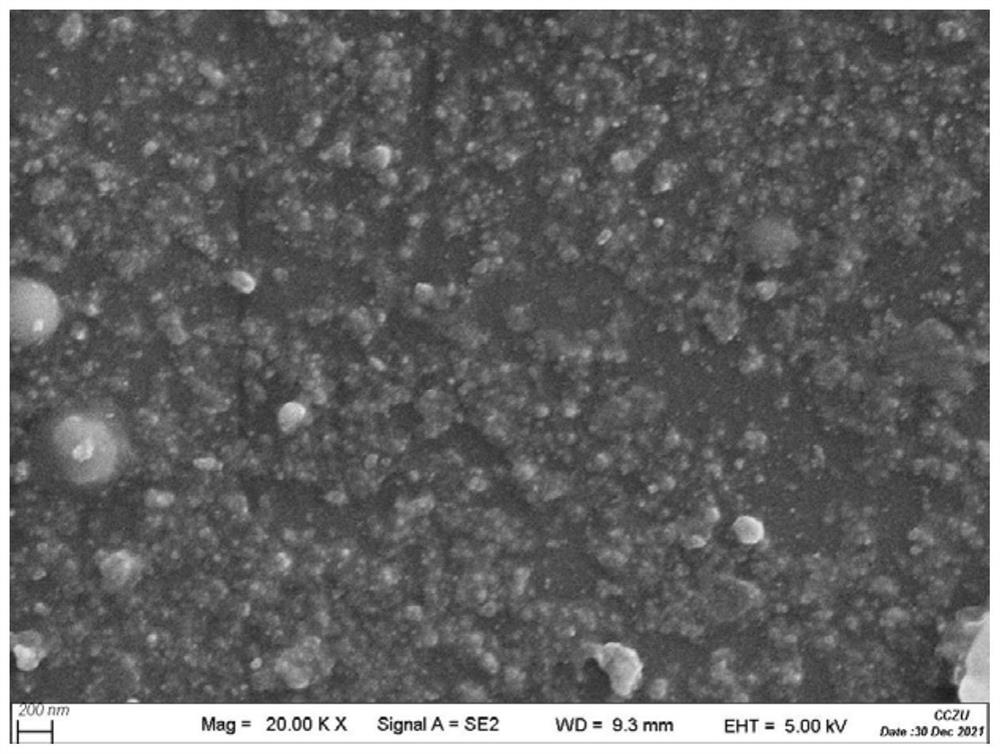

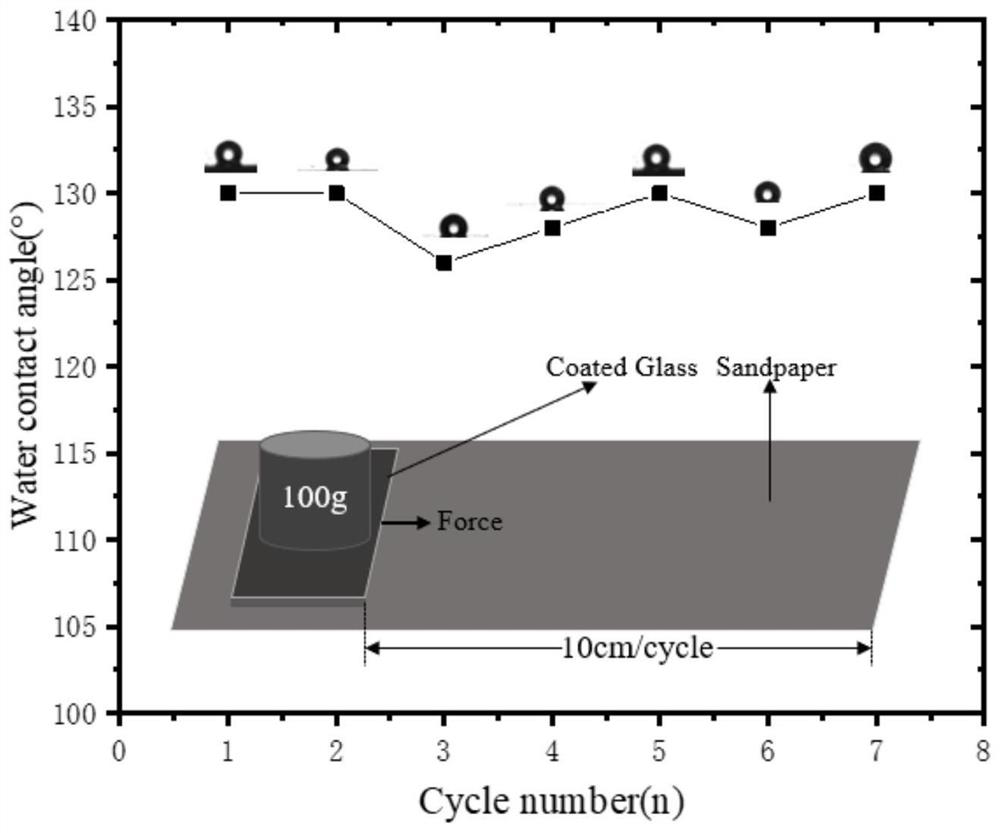

[0026] (3) The glass substrate with two layers of MOFs coating was immersed in chloroform for 48h, and vacuum-dried at 100°C for 12h to obtain a transparent hydrophobic self-cleaning MOFs coating. The measured average transmittance in the v...

Embodiment 2

[0028] The preparation of 3-aminopropyltriethoxysilane on the glass substrate is the same as that in Example 1.

[0029] (1) The glass substrate attached to 3-aminopropyltriethoxysilane was immersed in 100 mL of N,N-dimethylformamide solution containing 5.95 g of tetrafluoroterephthalic acid in a hydrothermal reaction kettle at 120°C for 4 hours of airtight reaction. Then, it was immersed in 100 mL of N,N-dimethylformamide solution containing 5.83 g of zirconium chloride and reacted at 120° C. for 20 min, ending one cycle. The same procedure was cycled 5 times to prepare 5-layer MOFs coatings on glass substrates.

[0030] (2) The glass substrate with 5 layers of MOFs coating was immersed in chloroform for 48h and vacuum dried at 100°C for 12h to obtain a transparent hydrophobic self-cleaning MOFs coating. The measured average transmittance in the visible light range is as high as 92.26%, the water contact angle is 130°, and the hysteresis angle is 10°.

[0031] It can be obt...

Embodiment 3

[0036] The preparation of 3-aminopropyltriethoxysilane on the glass substrate is the same as that in Example 1.

[0037] (1) The glass substrate attached to 3-aminopropyltriethoxysilane was immersed in a 100 mL N,N-dimethylformamide solution containing 5.95 g of tetrafluoroterephthalic acid in a hydrothermal reaction kettle at 120°C for a closed reaction for 4 hours. Then, it was immersed in 100 mL of N,N-dimethylformamide solution containing 5.83 g of zirconium chloride and reacted at 120° C. for 20 min, ending one cycle. The same procedure was cycled 6 times to prepare 6-layer MOFs coatings on glass substrates.

[0038] (2) The glass substrate with 6 layers of MOFs coating was immersed in chloroform for 48h and vacuum dried at 100°C for 12h to obtain a transparent hydrophobic self-cleaning MOFs coating. The measured average transmittance in the visible light range is as high as 91.26%, the water contact angle is 130°, and the hysteresis angle is 10°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com