Preparation method of polycarboxylic acid admixture for machine-made sand high-strength concrete

A technology of high-strength concrete and polycarboxylic acid, which is applied in the field of concrete for building materials, can solve the problems of high water demand, large loss of fluidity, and rough surface morphology of concrete, and achieve excellent slump retention, dispersion and retention, enhanced anchorage, The effect of strong initial dispersion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

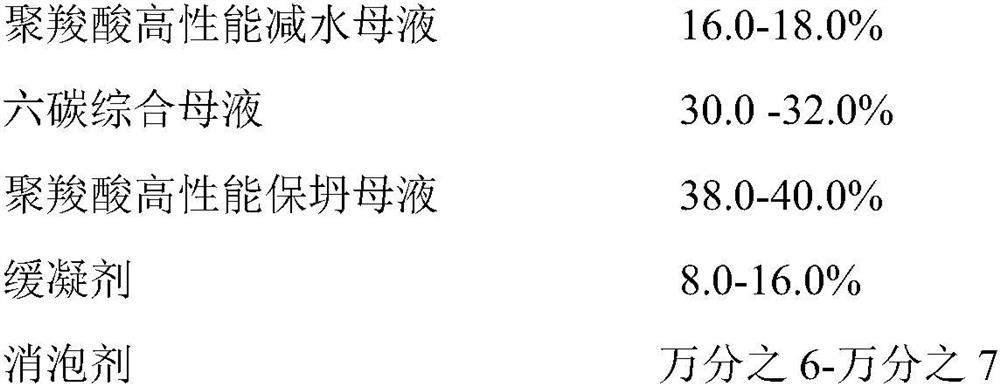

Method used

Image

Examples

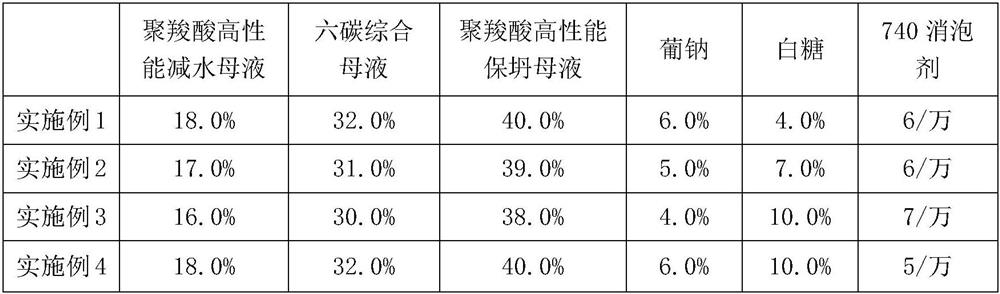

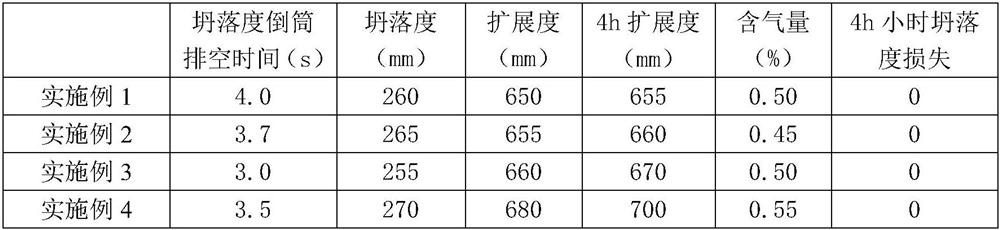

Embodiment 1

[0039](1) Preparation of PC-1: inject deionized water with a temperature of 25-35 ° C in the chemical kettle, add isopentenyl polyoxyethylene ether macromonomer, start the mixer to stir and dissolve; After the isopentenyl polyoxyethylene ether macromonomer is completely dissolved, the polyethylene glycol monomethyl ether esterified macromonomer is pumped into the reaction kettle to ensure that the temperature in the reaction kettle is controlled at 20-32 °C when starting to drip. During the synthesis of mother liquor, the temperature of the reaction kettle should be controlled at 50-58 °C; add hydrogen peroxide to the reaction kettle, firstly add solution A at a constant speed for two minutes, and then add solution B at a constant speed to ensure that solution A is added within 3 hours, and solution B is added dropwise at a constant speed. The solution was added in 2.5 hours. During the dropwise addition of solutions A and B, the temperature of the material was controlled at 40...

Embodiment 2

[0043] (1) Preparation of PC-1: inject deionized water with a temperature of 25-35 ° C in the chemical kettle, add isopentenyl polyoxyethylene ether macromonomer, start the mixer to stir and dissolve; After the isopentenyl polyoxyethylene ether macromonomer is completely dissolved, the polyethylene glycol monomethyl ether esterified macromonomer is pumped into the reaction kettle to ensure that the temperature in the reaction kettle is controlled at 20-32 °C when starting to drip. During the synthesis of mother liquor, the temperature of the reaction kettle should be controlled at 50-58 °C; add hydrogen peroxide to the reaction kettle, firstly add solution A at a constant speed for two minutes, and then add solution B at a constant speed to ensure that solution A is added within 3 hours, and solution B is added dropwise at a constant speed. The solution was added in 2.5 hours. During the dropwise addition of solutions A and B, the temperature of the material was controlled at 4...

Embodiment 3

[0047] (1) Preparation of PC-1: inject deionized water with a temperature of 25-35 ° C in the chemical kettle, add isopentenyl polyoxyethylene ether macromonomer, start the mixer to stir and dissolve; After the isopentenyl polyoxyethylene ether macromonomer is completely dissolved, the polyethylene glycol monomethyl ether esterified macromonomer is pumped into the reaction kettle to ensure that the temperature in the reaction kettle is controlled at 20-32 °C when starting to drip. During the synthesis of mother liquor, the temperature of the reaction kettle should be controlled at 50-58 °C; add hydrogen peroxide to the reaction kettle, firstly add solution A at a constant speed for two minutes, and then add solution B at a constant speed to ensure that solution A is added within 3 hours, and solution B is added dropwise at a constant speed. The solution was added in 2.5 hours. During the dropwise addition of solutions A and B, the temperature of the material was controlled at 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com