Method for preparing polyamide by anionic polymerization and polyamide prepared thereby

An anionic polymerization and polyamide technology, which is applied in the field of ultra-high molecular weight polyamide and preparation of ultra-high molecular weight polyamide, can solve the problems of prolonging the polymerization time, increasing polyamide, gelation, etc., and achieve the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] In one aspect, the present invention provides a method for preparing a polyamide by anionic polymerization of lactams in the presence of a polymerization catalyst, an activator and a molecular weight regulator with a weight average molecular weight of 100,000 g / mol to 200,000 g / mol The method of mol polyamide, wherein the content of the activator is 0.002 to 20 parts by weight and the content of the molecular weight regulator is 0.01 to 10 parts by weight based on 100 parts by weight of the lactam.

[0035] monomer

[0036] The polyamide according to one embodiment of the present invention is prepared by anionic polymerization of lactams. Therefore, lactams are used as monomers for the preparation of polyamides. Specifically, the number of carbon atoms in the ring of the lactam is 4 to 12, and the lactam may be selected from the group consisting of laurolactam, caprolactam, piperidinone, pyrrolidone, enantholactam ( At least one of enantolactam and capryllactam, but...

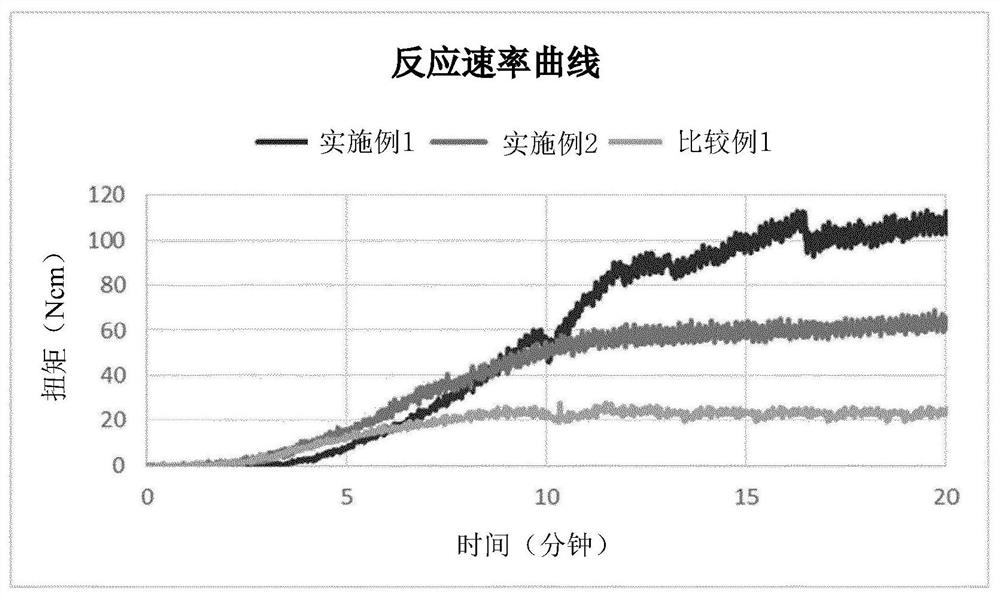

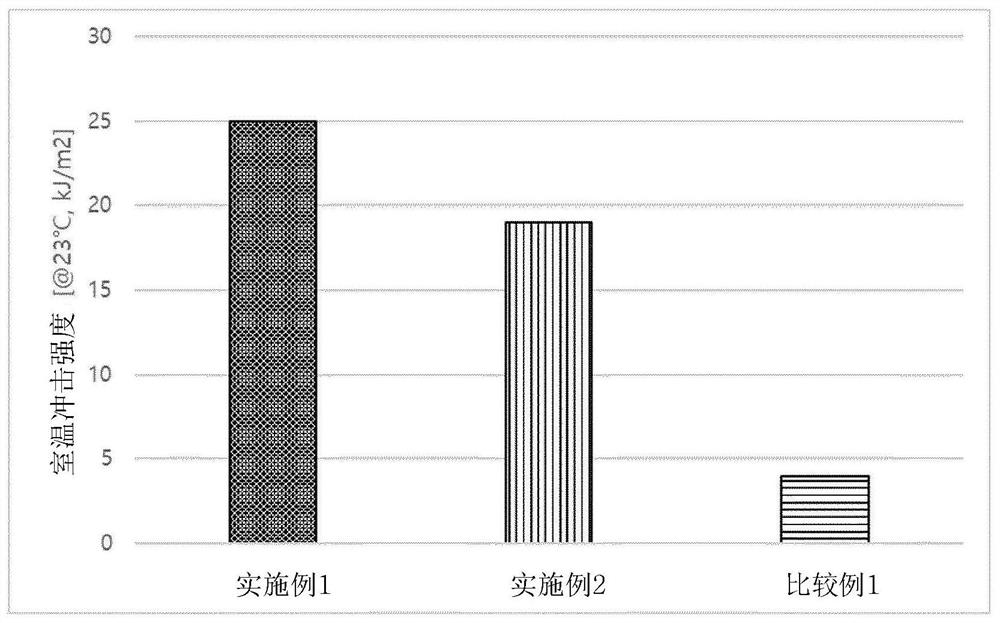

Embodiment 1

[0069] The flask was kept at 70°C under vacuum to remove moisture from the flask. After the vacuum applied to the flask was released, 50 g of laurolactam (LL), 0.03 g of sodium hydride (NaH), 0.30 g of vinylbisstearamide (EBS) were added to the flask, and the temperature was raised under vacuum. to 165°C. The reaction temperature was set to 240°C, and the hydrogen gas generated when the above-mentioned raw materials were melted was removed while injecting nitrogen gas. 0.04 g of toluene diisocyanate (TDI) was added, and the reaction was carried out for 20 minutes. After 20 minutes, 50 ml of an aqueous formic acid solution (formic acid:distilled water=1:1, v / v) was added to the flask to terminate the reaction to obtain 48 g of polymerized polyamide.

Embodiment 2

[0071] 50 g of polyamide was prepared in the same manner as in Example 1, except that the amount of TDI added was 0.17 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com