Preparation method of spherical aluminum oxide and prepared spherical aluminum oxide

A spherical alumina, alumina technology, applied in chemical instruments and methods, aluminum compounds, inorganic chemistry, etc., can solve the problems of electronic products with low voltage withstand performance, circuit board breakdown, etc., to reduce the dielectric constant, increase Liquidity, good for heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

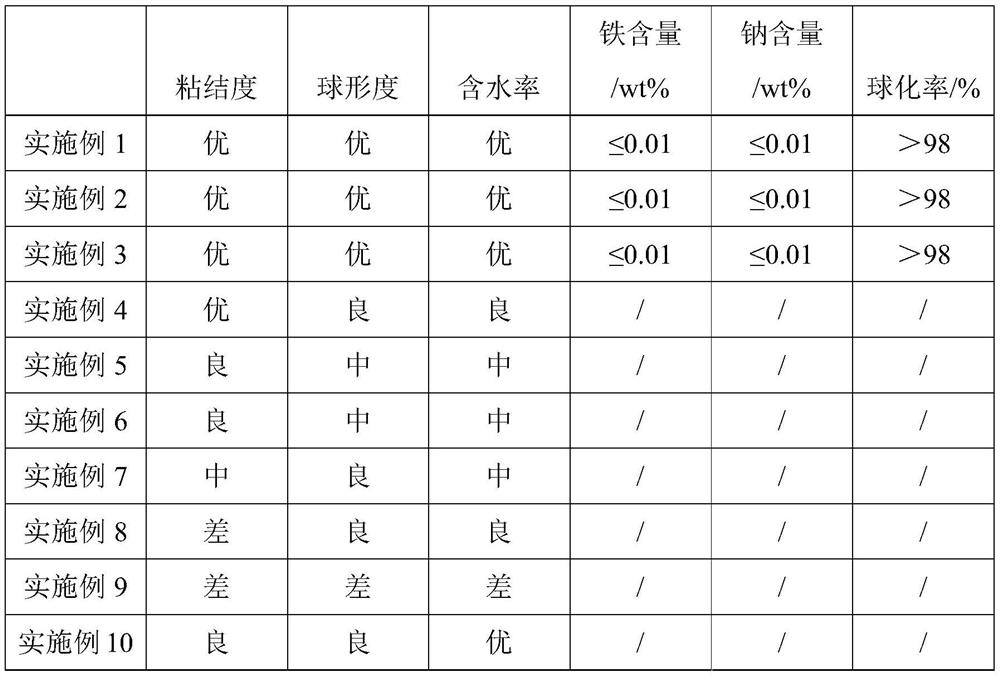

Examples

preparation example Construction

[0025] In order to improve the spheroidization rate and purity of spherical alumina, a first aspect of the present invention provides a method for preparing spherical alumina, comprising one demagnetization and flame spraying, and one demagnetization includes the following steps:

[0026] (1) adding aluminum oxide to ammonium salt and grinding, obtaining the aluminum oxide with particle diameter of 0.5-30 μm;

[0027] (2) Alumina and water are added to the stirring tank with the magnetic bar, stirred for 30 to 50 min, and the stirring temperature is 85 to 95 ° C, then filtered, washed with detergent, and dried to obtain a demagnetization alumina;

[0028] The flame spraying includes the following steps: spraying the primary demagnetized alumina through flame spraying, and the temperature of the flame spraying is 2300-2800° C. to obtain spherical alumina.

[0029] As a preferred embodiment, the ratio of alumina to water in the first demagnetization process is (0.4-0.6 g): 1 mL....

Embodiment approach

[0047] As a preferred embodiment, the preparation method of the spherical alumina also includes secondary demagnetization, which includes the following steps:

[0048] (1) adding the spherical alumina and water obtained by flame spraying into the stirring tank with the magnetic bar, and stirring for 30~50min;

[0049] (2) Filtration and drying to obtain secondary demagnetized spherical alumina.

[0050] As a preferred embodiment, the ratio of spherical alumina to water in the secondary demagnetization process is (0.1-0.3 g): 1 mL.

[0051] As a preferred embodiment, in the secondary demagnetization, the drying time is 3-6 hours, and the temperature is 150-200°C.

[0052] During the flame spraying process, the residual iron may be adsorbed on the surface of the spherical alumina, and the sodium inside the alumina may also be precipitated. Therefore, after the flame spraying, the iron and sodium can be further removed by the secondary demagnetization, so that the The iron and so...

Embodiment 1

[0057] A preparation method of spherical alumina, comprising primary demagnetization and secondary demagnetization, comprising the following steps:

[0058] (1) Alumina is added to the ammonium salt and ground to obtain a ground alumina with a particle size of 20 μm, the ammonium salt is ammonium bicarbonate and ammonium chloride, and the weight ratio is 1:0.75, and the ammonium salt accounts for the alumina 1wt%. ;

[0059] (2) adding grinding alumina and water to the stirring tank of laying the magnetic bar, the ratio of the grinding alumina and water is 0.5g: 1mL, stirring for 40min, the temperature of stirring is 90 ℃, then filter, add kerosene for washing, Dry, the drying temperature is 375 ℃, and the drying time is 2.5h to obtain a demagnetized alumina;

[0060] (3) once demagnetized alumina is sprayed by flame, and the temperature of flame spray is 2500 ℃ to obtain spherical alumina;

[0061] (4) adding spherical alumina and water to the stirring tank with the magnet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com