Corrosion inhibitor suitable for acidification at 200 DEG C as well as preparation method and application of corrosion inhibitor

A technology of corrosion inhibitor and synergist for acidification, which is applied in the direction of chemical instruments and methods, scale removal and water softening, drilling compositions, etc. It can solve the problems that cannot meet the deep layer and achieve the effect of reducing the risk of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment provides a corrosion inhibitor for acidification, and the corrosion inhibitor for acidification includes component A and component B.

[0037] Wherein, component A is prepared by the following method:

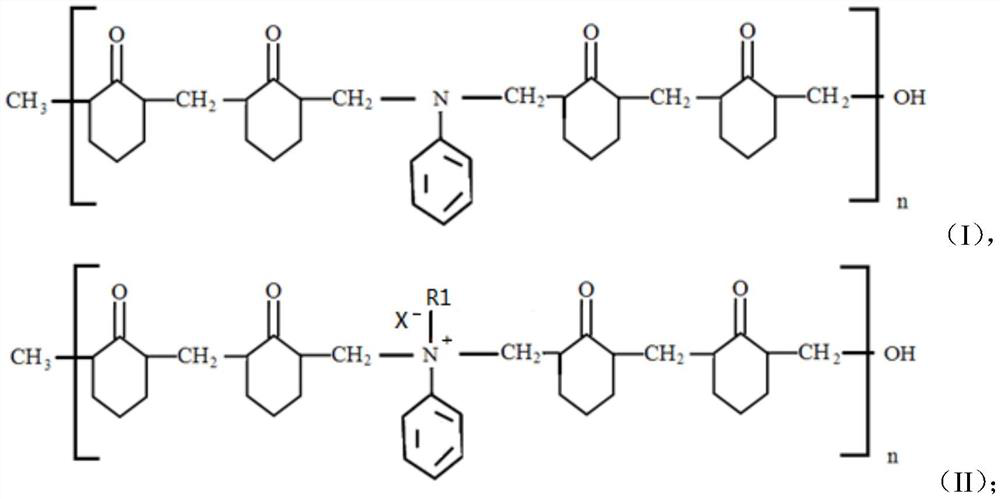

[0038] Add 30 parts of aldosterone amine condensate to the reaction kettle, and heat the aldosterone amine condensate to 40-50°C, then add 5 parts of chlorinated-1-benzyl quinoline salt and 10 parts of propyne in turn under stirring The alcohol propoxy compound, 17 parts of formic acid, 19 parts of formamide, 9 parts of ethylene glycol, and 10 parts of O-20 are mixed uniformly to obtain the component A of this embodiment, which is recorded as formula 1.

[0039] Component B in this embodiment is potassium pyroantimonate, and the mass ratio of component A to component B is 5.0:1.5.

Embodiment 2

[0041] This embodiment provides a corrosion inhibitor for acidification, and the corrosion inhibitor for acidification includes component A and component B.

[0042] Add 35 parts of aldosterone amine condensate to the reaction kettle, and heat the aldosterone amine condensate to 40-50 ° C, then add 10 parts of propargyl alcohol propoxy compound, 17 parts of formic acid, 19 parts of Formamide, 9 parts of ethylene glycol, and 10 parts of O-20 were mixed uniformly to obtain component A of this embodiment, which is designated as formula 2.

[0043] Component B in this embodiment is potassium pyroantimonate, and the mass ratio of component A to component B is 5.0:1.5.

Embodiment 3

[0045] This embodiment provides a corrosion inhibitor for acidification, and the corrosion inhibitor for acidification includes component A and component B.

[0046] Wherein, component A is prepared by the following method:

[0047] Add 30 parts of aldosterone amine condensate to the reaction kettle, and heat the aldosterone amine condensate to 40-50 ° C, then add 5 parts of chlorinated-1-benzyl quinoline salt and 10 parts of propyne in turn under stirring The alcohol ethoxy compound, 17 parts of acetic acid, 19 parts of N,N-dimethylformamide, 9 parts of ethanol, and 10 parts of O-20 were mixed uniformly to obtain the component A of this example, which is designated as formula 3.

[0048] Component B in this embodiment is sodium molybdate, and the mass ratio of component A to component B is 5.0:1.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com