Oyster shell/coffee residue cat litter and preparation method thereof

A technology of oyster shells and coffee grounds, applied in animal houses, applications, animal husbandry, etc., can solve the problems of complex raw materials, high preparation costs, and high production costs of cat litter, achieve low recycling and processing costs, and improve utilization rates , Increase the effect of national taxation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

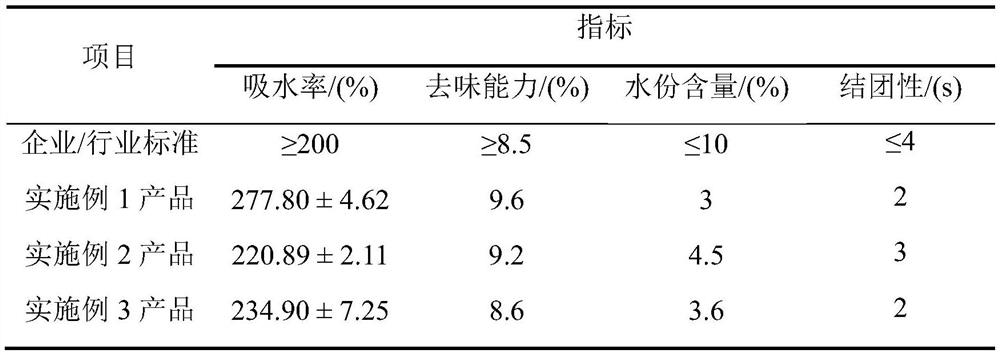

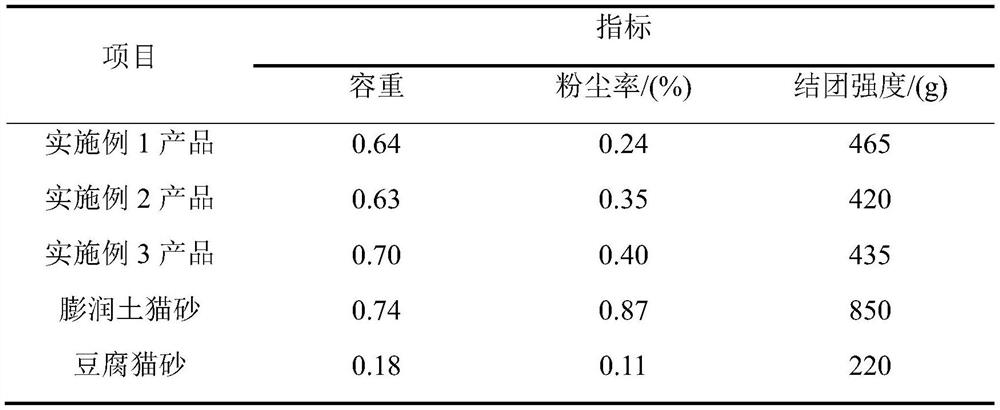

Embodiment 1

[0016] (1) Selection and processing of raw materials: select oyster shells with no fleshy, no entanglement of debris and no lesions on the surface. Rinse with tap water and dry naturally in the open air. The dried oyster shells are first crushed into pieces smaller than 2cm with a crushing tool, and then further crushed and ground into powder with a crushing mill. The crushing power is 37KW, the crushing time is 5min-10min, and the larger particles are removed by passing through an 80-mesh sieve. and impurities. Subsequently, the moisture content of the oyster shell powder was determined according to the national standard (GB5009.3 2016), and the moisture content of the oyster shell powder was controlled to be less than 3% by drying in a dryer, and it was temporarily stored in a dry environment for future use. Select non-mildewed coffee grounds, dry them in a dryer at 50°C, measure the water content of the coffee grounds powder according to the national standard (GB5009.32016...

Embodiment 2

[0020] (1) Selection and processing of raw materials: select oyster shells with no fleshy, no entanglement of debris and no lesions on the surface. Rinse with tap water and dry naturally in the open air. The dried oyster shells are first crushed into pieces smaller than 2cm with a crushing tool, and then further crushed and ground into powder with a crushing mill. The crushing power is 37KW, the crushing time is 5min-10min, and the larger particles are removed by passing through an 80-mesh sieve. and impurities. Subsequently, the moisture content of the oyster shell powder was determined according to the national standard (GB5009.3 2016), and the moisture content of the oyster shell powder was controlled to be less than 3% by drying in a dryer, and it was temporarily stored in a dry environment for future use. Select non-mildewed coffee grounds, dry them in a dryer at 50°C, measure the water content of the coffee grounds powder according to the national standard (GB5009.32016...

Embodiment 3

[0024] (1) Selection and processing of raw materials: select oyster shells with no fleshy, no entanglement of debris and no lesions on the surface. Rinse with tap water and dry naturally in the open air. The dried oyster shells are first crushed into pieces smaller than 2cm with a crushing tool, and then further crushed and ground into powder with a crushing mill. The crushing power is 37KW, the crushing time is 5min-10min, and the larger particles are removed by passing through an 80-mesh sieve. and impurities. Subsequently, the moisture content of the oyster shell powder was determined according to the national standard (GB5009.3 2016), and the moisture content of the oyster shell powder was controlled to be less than 3% by drying in a dryer, and it was temporarily stored in a dry environment for future use. Select non-mildewed coffee grounds, dry them in a dryer at 50°C, measure the water content of the coffee grounds powder according to the national standard (GB5009.32016...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com