Programmable liquid drop moving system based on hydrophobic magnetoelastic film and driving method thereof

A mobile system and hydrophobic technology, applied in chemical instruments and methods, laboratory containers, laboratory utensils, etc., can solve the problem of liquid droplet physical and chemical properties interfering with experimental results, liquid droplets doped with magnetic materials, and physical and chemical properties affecting experiments Results and other issues, to achieve the effect of wide application value, high tolerance, good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

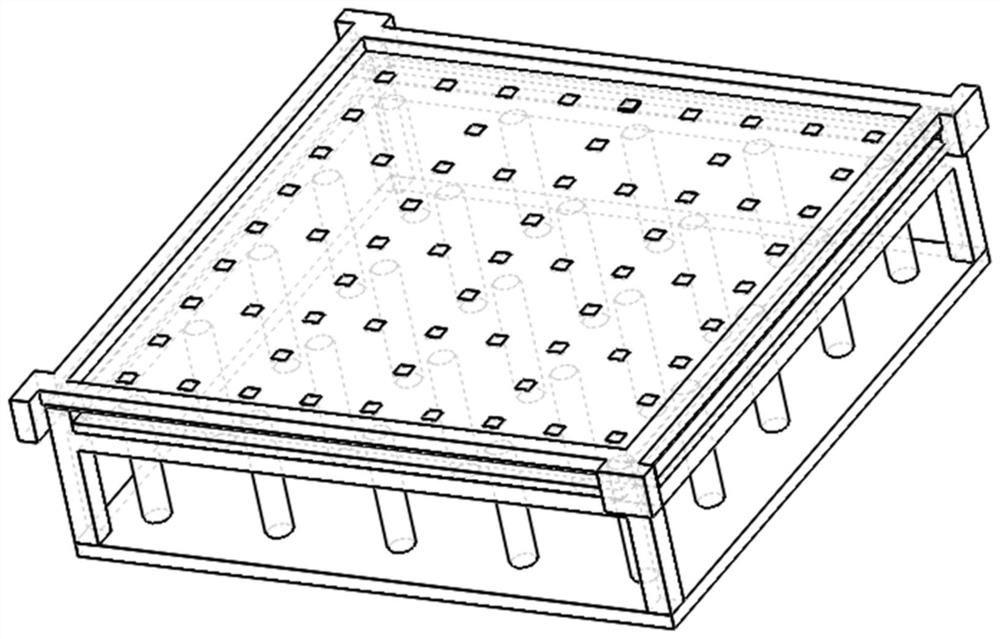

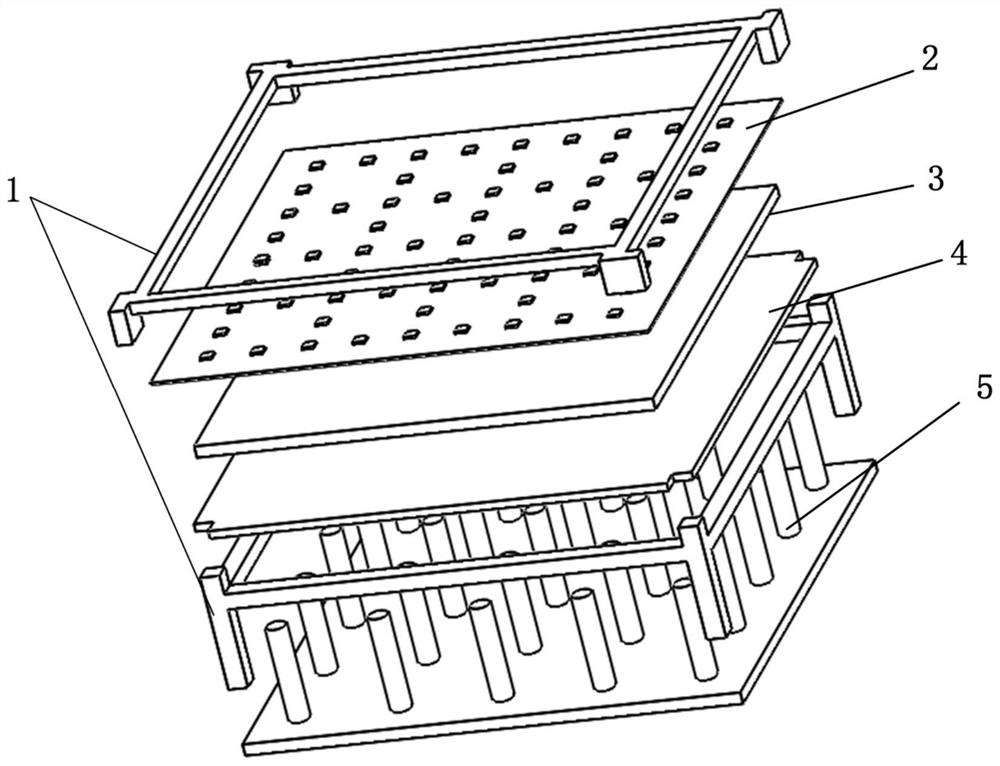

[0047] like figure 1 and figure 2 As shown, the programmable droplet movement system based on the hydrophobic magneto-elastic film includes a coil group array 5, a PMMA support plate 4, a silicone rubber layer 3 and a hydrophobic magneto-elastic film arranged from bottom to top on the fixed support 1 2, and a current control system connected to the coil set array 5; specifically,

[0048] like figure 2 As shown, the fixed bracket 1 is composed of a bottom plate, a lower bracket and an upper bracket arranged in sequence from bottom to top;

[0049] Specifically, the bottom plate is a horizontally arranged plate body;

[0050] The lower bracket is composed of a first rectangular frame and four outriggers, the four outriggers are vertically arranged and fixed at the four corners of the first rectangular frame, and the upper part of the four outriggers is partially located above the first rectangular frame; The size of the first rectangular frame is smaller than the size of ...

Embodiment 2

[0060] A preparation method of the hydrophobic magnetoelastic thin film of the programmable magnetic field control droplet moving system described in Embodiment 1, the specific steps are:

[0061] Step 1. Mold making:

[0062] According to the size of the hydrophobic magneto-elastic film 2 of Example 1, the three-dimensional model of the mold used for the production of the hydrophobic magneto-elastic film was designed using a computer, and high-precision 3D printing was used to obtain the magnetic block production mold as shown in Figure 4 and as shown in Figure 4. Figure 5 The shown hydrophobic magnetoelastic film fabrication mold; specifically,

[0063] As shown in Figure 4, the magnetic block manufacturing mold is a square module, and four square grooves in the shape of a square are evenly distributed on the square surface. The groove width of each positive direction groove is 3mm and the groove depth is 0.5mm. mm;

[0064] like Figure 5 As shown, the hydrophobic magne...

Embodiment 3

[0075] The programmable magnetic field control droplet movement system can control the horizontal and vertical movement of the droplets on the platform, the oblique continuous and uniform movement, and the multi-droplet mixing function;

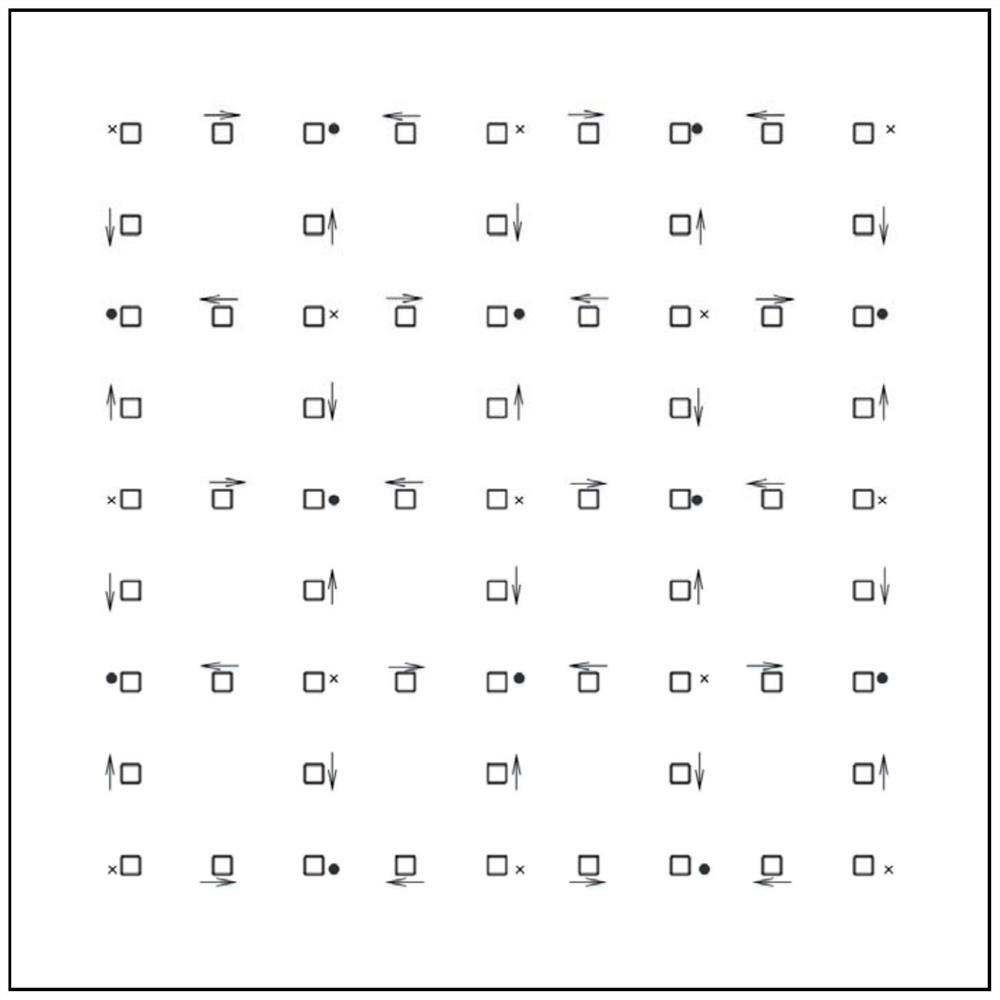

[0076] Specifically, as Image 6 As shown in the figure, the 25 cylindrical coils in the coil group array 5 are numbered and named according to the number of rows and columns where the cylindrical coils are located; and then the current of the corresponding cylindrical coils is specifically controlled to realize the droplet directional movement;

[0077] 1. A method of utilizing a programmable magnetic field to control a droplet movement system to drive a droplet to carry out lateral or longitudinal movement on a platform, the concrete steps of which are:

[0078] Take the droplet moving laterally from the position of coil (1,1) to coil (1,2) from left to right as an example; specifically,

[0079] The coil at the starting point on the left...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com