High-performance ultrathin asphalt wearing layer and paving method thereof

A wear layer, high-performance technology, applied to cohesive pavement paved on site, roads, buildings, etc., to reduce the difficulty of preparation and construction, good bonding effect, and short surface drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

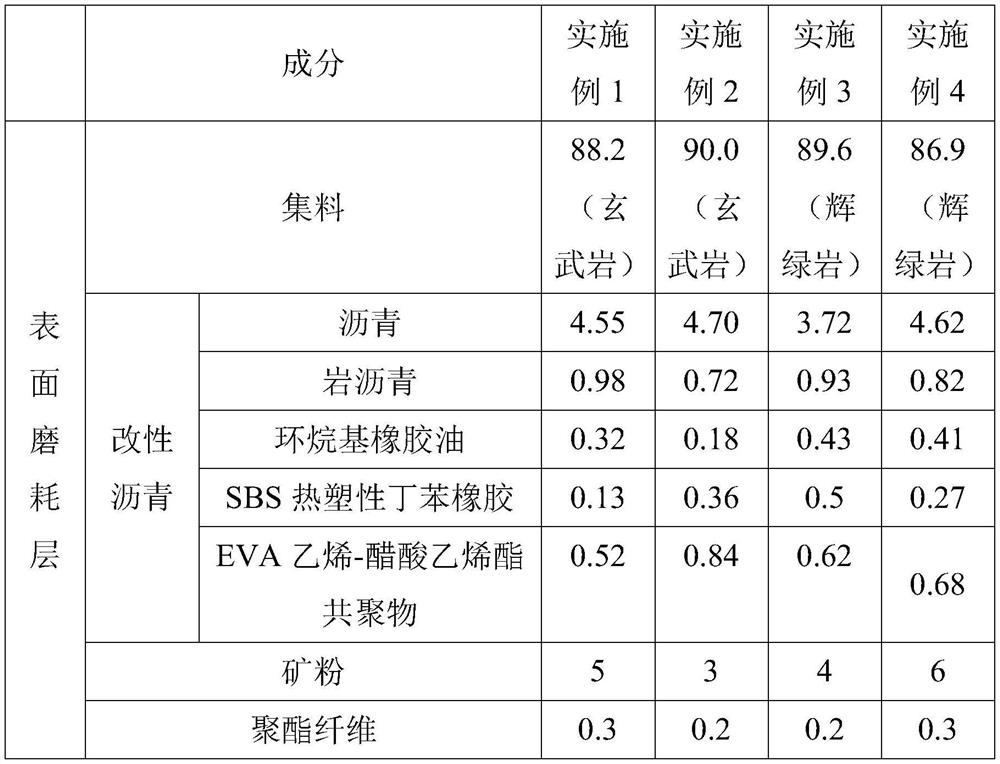

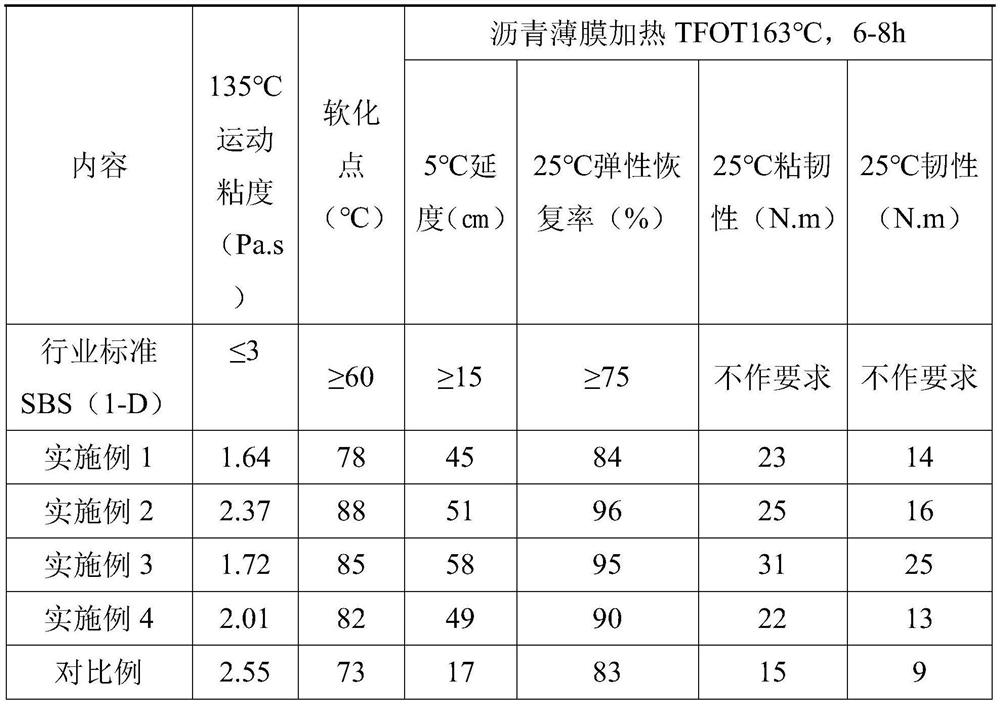

Embodiment 1-4

[0053] The ultra-thin asphalt wear layers provided in Examples 1-4 of the present invention all include a waterproof adhesive layer arranged on the original road surface and a surface abrasion layer arranged above the waterproof adhesive layer;

[0054] The sources of raw materials used in Examples 1-4 of the present invention are as follows:

[0055] Aggregate (diabase): purchased from Zecheng Mineral Products Processing Plant in Lingshou County, with a particle size of 1.5-7mm;

[0056] Aggregate (basalt): purchased from Fujian Nanan Xinhongsen Stone Co., Ltd., the particle size is 2-8mm;

[0057] Mineral powder: purchased from Lingshou County Jiangfeng Mineral Products Processing Plant, the particle size is less than 0.074mm;

[0058] Polyester fiber: purchased from Changzhou Tianyi Co., Ltd., about 6mm in length;

[0059] Asphalt: purchased from Shandong Lianhai Petrochemical Co., Ltd.;

[0060] Rock asphalt: purchased from Anhui Zhongyin Co., Ltd.;

[0061] Naphthenic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| stability | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com