Preheat treatment method for 17CrNiMo6 material

A technology for preparing heat treatment and heat treatment equipment, which is applied in the field of heat treatment of metal materials, can solve the problems of large floor space, difficulty, and high cost of isothermal normalizing production lines, and achieve the effects of reducing floor space, reducing technical difficulty, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

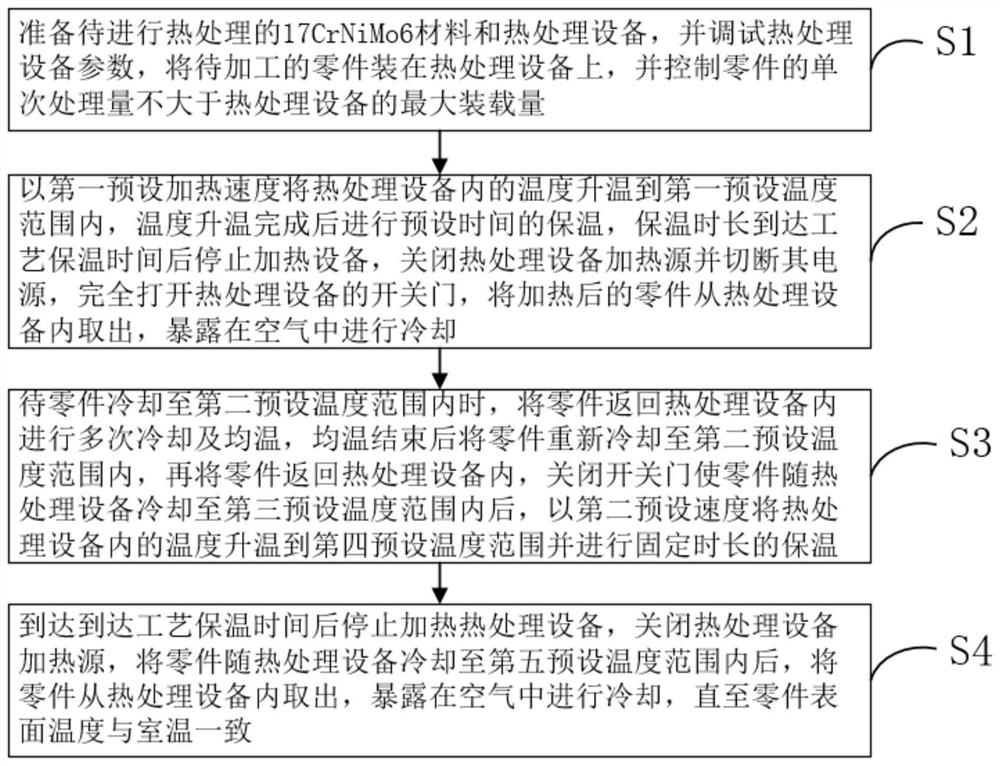

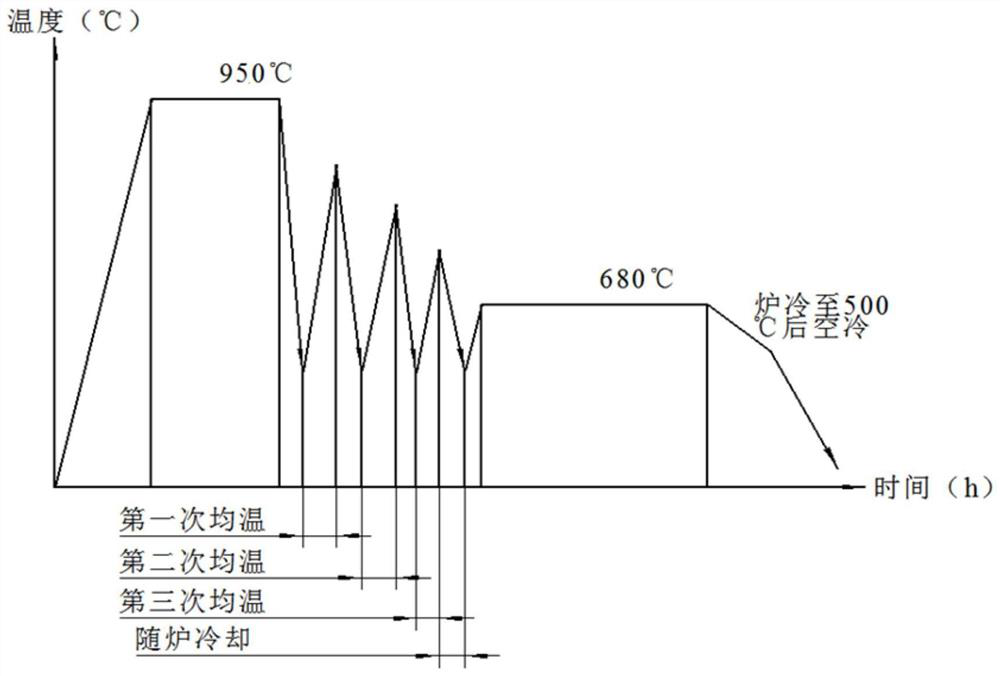

[0033] The example is basically as attached figure 1 Shown: a 17CrNiMo6 material preparatory heat treatment method, comprising the following steps:

[0034] Step S1, prepare the 17CrNiMo6 material to be heat treated and the heat treatment equipment, adjust the parameters of the heat treatment equipment, install the parts to be processed on the heat treatment equipment, and control the single processing capacity of the parts to be no greater than the maximum loading capacity of the heat treatment equipment;

[0035] Step S2, the temperature in the heat treatment equipment is raised to within the first preset temperature range at the first preset heating speed, after the temperature rise is completed, the heat preservation for a preset time is performed, and the heating equipment is stopped after the heat preservation time reaches the process heat preservation time, and the heat treatment is turned off. Equipment heating source, fully open the switch door of the heat treatment e...

Embodiment 2

[0055] This embodiment is basically the same as the first embodiment, the difference is that a circulating fan, specifically a blower, is fixedly installed inside the trolley furnace.

[0056] The specific implementation process of this embodiment is basically the same as that of the first embodiment, and the difference is:

[0057] The second step is to open the natural gas valve of the trolley furnace, and raise the temperature in the trolley furnace to 950 ℃ at 180 ℃ / h. The temperature in the trolley furnace of the valve console is kept at 950 °C for 45 minutes. During the heating and heat preservation period, the power of the blower is turned on synchronously, so that the blower can stir the heat in the trolley furnace.

[0058] The third step, after the holding time reaches 45min, close the natural gas valve to stop heating the trolley furnace, turn off the power supply of the blower, fully open the furnace door of the trolley furnace, and completely open the heated parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com