Super-resolution photoetching method based on two-color two-step absorption effect

A super-resolution and high-effect technology, which is applied in the direction of microlithography exposure equipment, photolithography exposure equipment, etc., can solve the problems of increasing system cost, expensive devices, and hindering popularization and application, so as to reduce the laser active area, increase the writing speed, The effect of reducing the line width of the engraved feature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below through examples and accompanying drawings, but the protection scope of the present invention should not be limited by this.

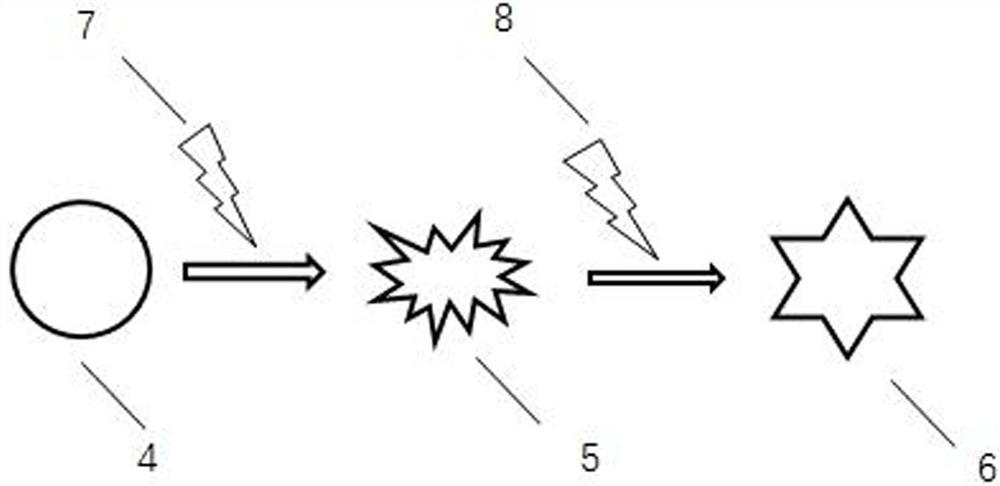

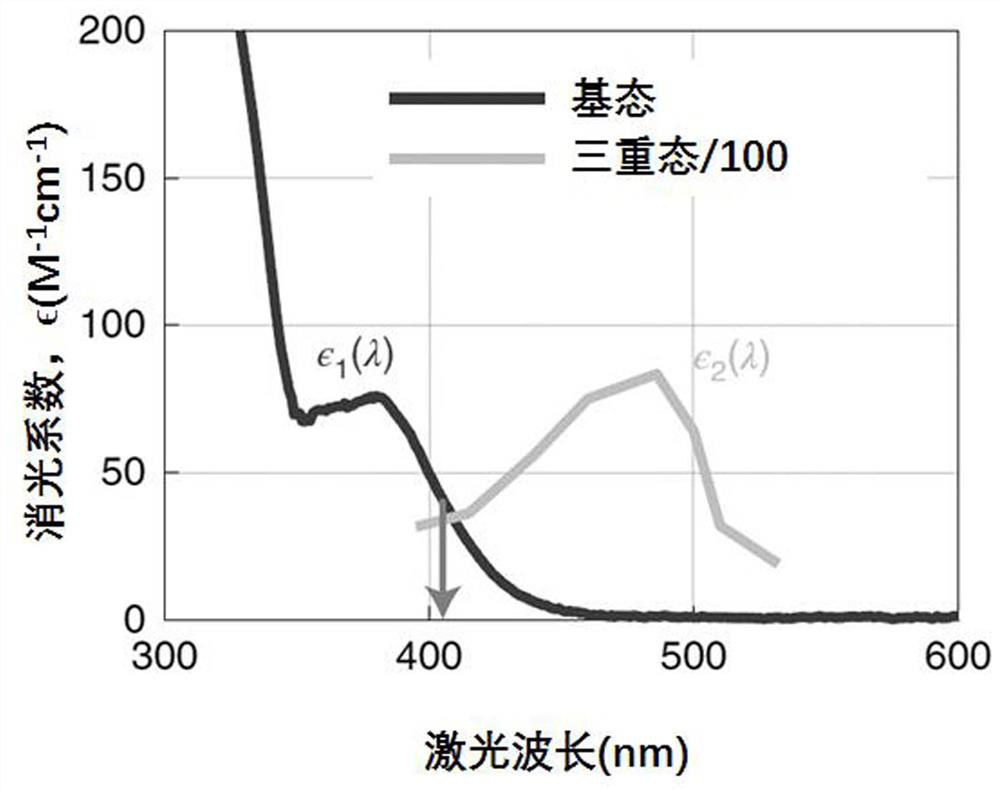

[0024] A super-resolution lithography method based on two-color two-step absorption effect, such as figure 1 shown, including the following steps:

[0025] (1) Coat the photoresist containing benzil photoinitiator on the glass substrate or silicon substrate, and place it at the focal plane of the objective lens of the photolithography system;

[0026] (2) Turn on the first absorption beam and adjust its optical power density , incident into the photoresist;

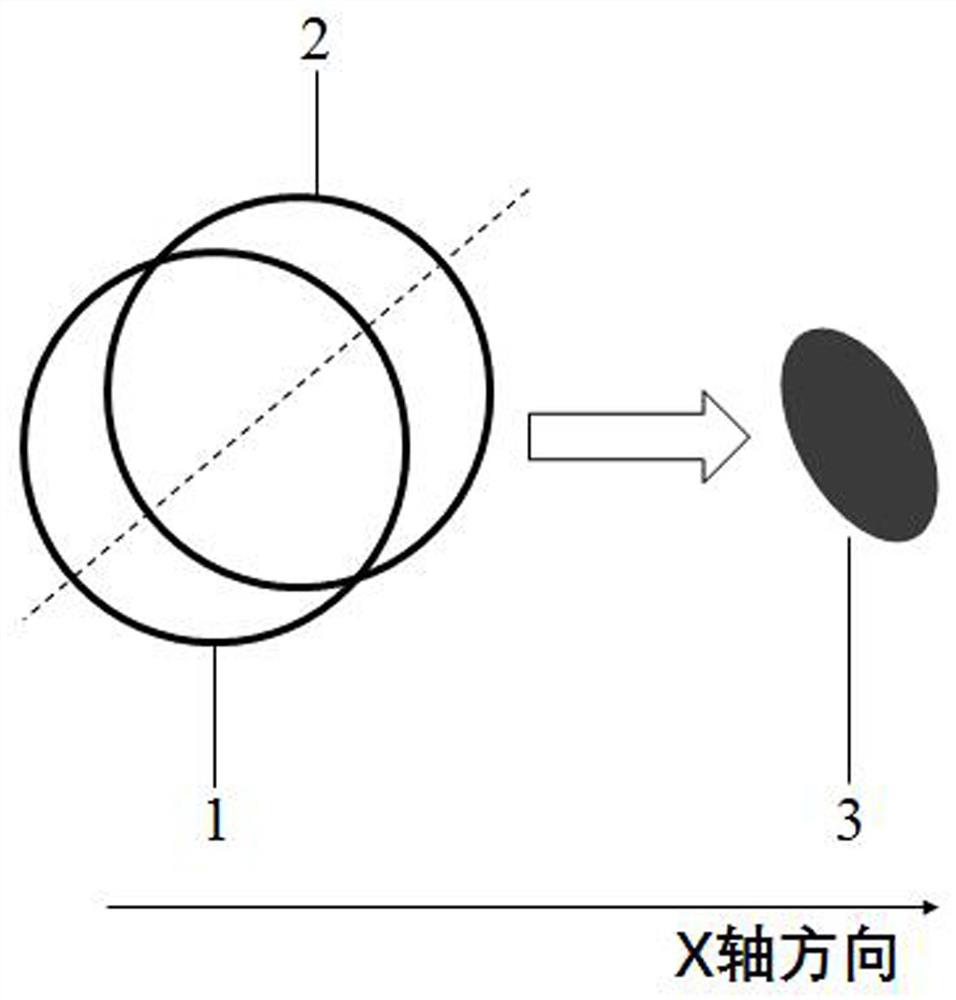

[0027] (3) Turn on the second absorption beam and adjust its optical power density , incident into the photoresist, and adjust the focusing center of the second absorption beam to coincide with the focusing center of the first absorption beam;

[0028] (4) Move the focus center of the first absorption beam and the second absorption...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com