Method for reducing surface alkali content of lithium battery positive electrode material

A technology of surface alkali content and positive electrode material, applied in battery electrodes, secondary batteries, electrode manufacturing, etc., can solve problems such as failure to meet the use requirements of power batteries, decrease in rate and cycle performance of positive electrode materials, and increase in cost, and achieve improvement. Crystal structure, avoidance of element loss, effect of improving crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

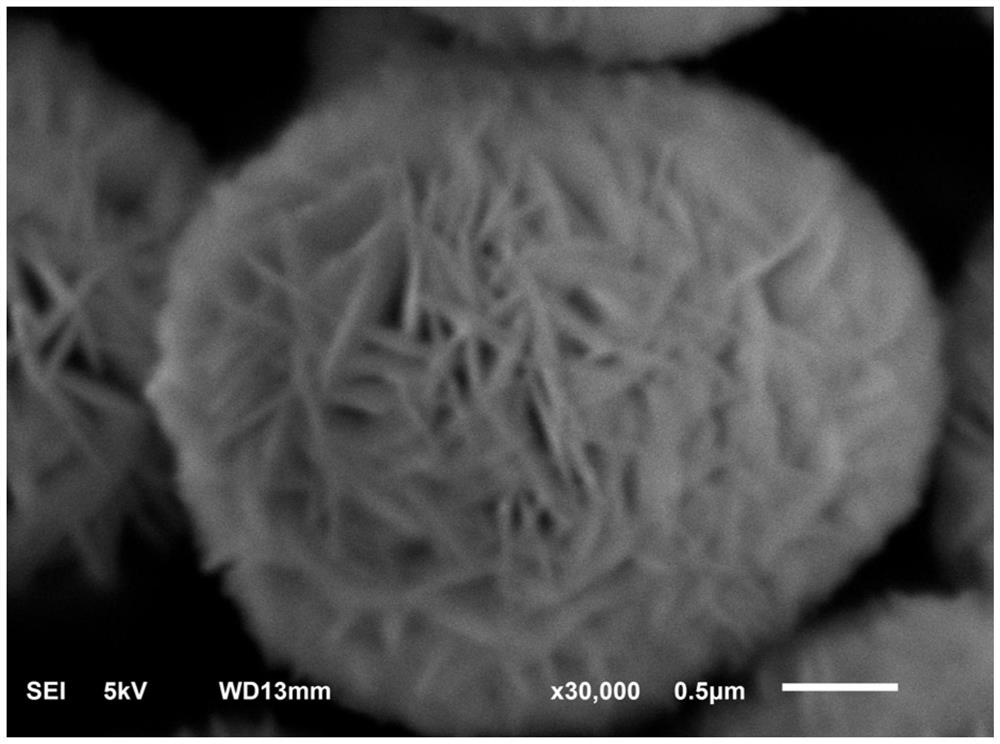

[0036] Embodiment 1: a method for reducing the alkali content on the surface of the positive electrode material of a lithium battery, including the following steps in sequence:

[0037] Step 1. In the preparation of Ni, the precursor of the positive electrode material for lithium ion batteries 0.7 Co 0.1 Mn 0.2 (OH) 2 After the co-precipitation reaction is completed, the pH is adjusted to 12.50 with sodium hydroxide, aged for 60 min, and then the lithium battery cathode material precursor Ni is removed with a filter press. 0.7 Co 0.1 Mn0.2 (OH) 2 in the mother liquor;

[0038] Step 2, remove the lithium battery cathode material precursor Ni from the mother liquor in the medium pressure filter in step 1 0.7 Co 0.1 Mn 0.2 (OH) 2 Carry out 2~4 times of circulating water washing, the washing temperature is 75 ℃, and then the water content is pressed to 15%. The quality of pure water used in each washing is 6 times that of the lithium battery cathode material precursor, an...

Embodiment 2

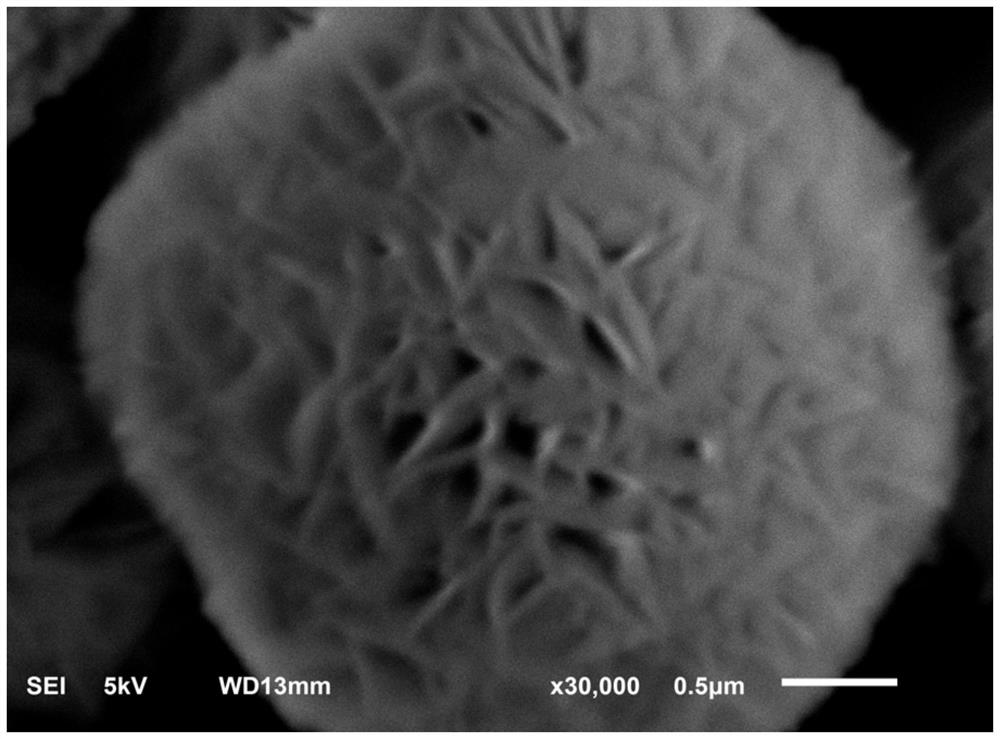

[0045] Embodiment 2: a method for reducing the alkali content on the surface of the positive electrode material of a lithium battery, including the following steps in sequence:

[0046] Step 1. In the preparation of Ni, the precursor of the positive electrode material for lithium ion batteries 0.85 Co 0.05 Mn 0.10 (OH) 2 After the co-precipitation reaction is completed, the pH is adjusted to 12.50 with sodium hydroxide, aged for 60 min, and then the lithium battery cathode material precursor Ni is removed with a filter press. 0.85 Co 0.05 Mn 0.10 (OH) 2 in the mother liquor;

[0047] Step 2, remove the lithium battery cathode material precursor Ni from the mother liquor in the medium pressure filter in step 1 0.85 Co 0.05 Mn 0.10 (OH) 2 Carry out 2~4 times of circulating water washing, the washing temperature is 75 ℃, and then the water content is pressed to 15%. The quality of pure water used in each washing is 6 times that of the lithium battery cathode material pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com