Automatic excrement drying machine

A drying machine, automatic technology, applied in the direction of drying machine, drying, non-progressive drying machine, etc., can solve the problems of uneven nutritional content, poor drying effect, burning damage, etc., and achieve environmental protection and drying High efficiency and the effect of expanding the drying area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

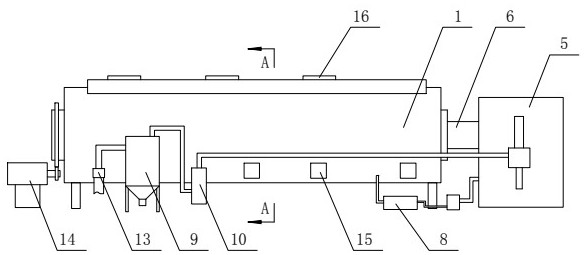

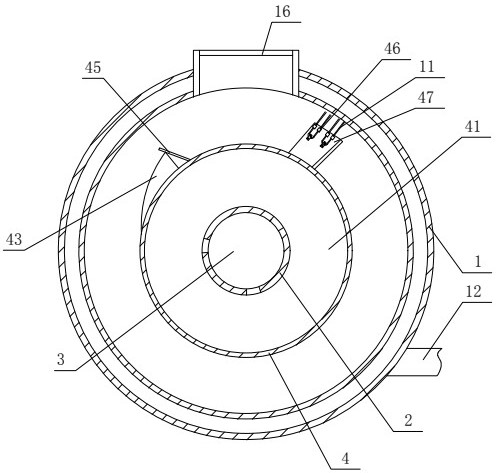

[0024] Referring to the drawings, the present invention provides an embodiment of an automatic excrement dryer. For the convenience of description, the figure 1 The left and right positions in this embodiment define the front and rear positions of this embodiment, and its direction is not a specific limitation to the present invention, and the following connection and installation can be understood as direct connection or indirect connection, and indirect connection means that it can pass through the middle. A component performs the connection or installation between two components.

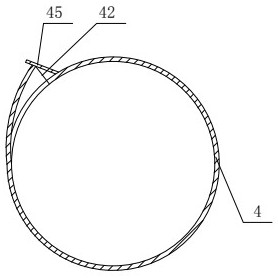

[0025] refer to Figure 1 to Figure 5 As shown in the figure, an automatic excrement dryer provided in this embodiment includes a drying cylinder 1, a hot air supply device connected to the front of the drying cylinder 1, and the front of the drying cylinder 1 is provided with a feed The outlet and the rear are provided with a discharge port and an air outlet. The cylinder wall of the drying cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com