Fermented walnut milk and preparation method thereof

A walnut milk and walnut technology, applied in the field of fermented walnut milk and its preparation, can solve the problems of walnut milk system instability, walnut protein denaturation, and easy stratification, so as to prevent fat from being easily oxidized, prevent protein acid precipitation, The effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

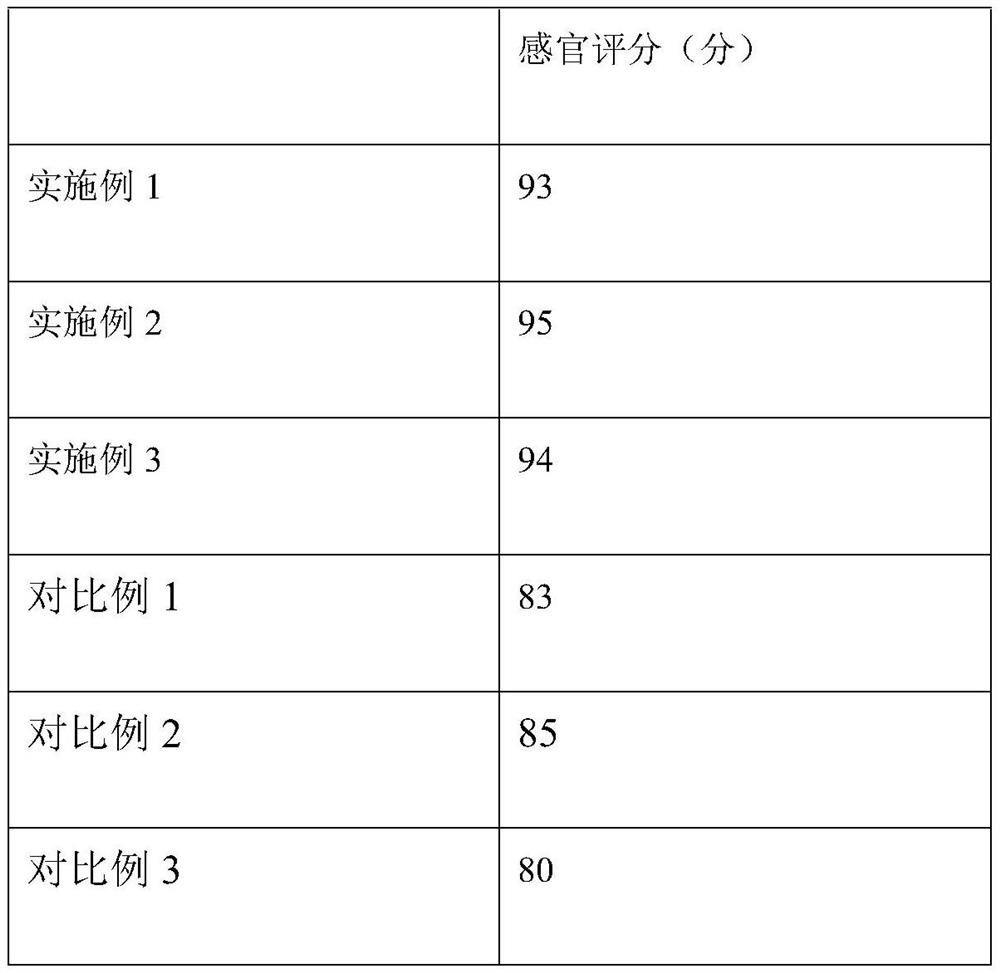

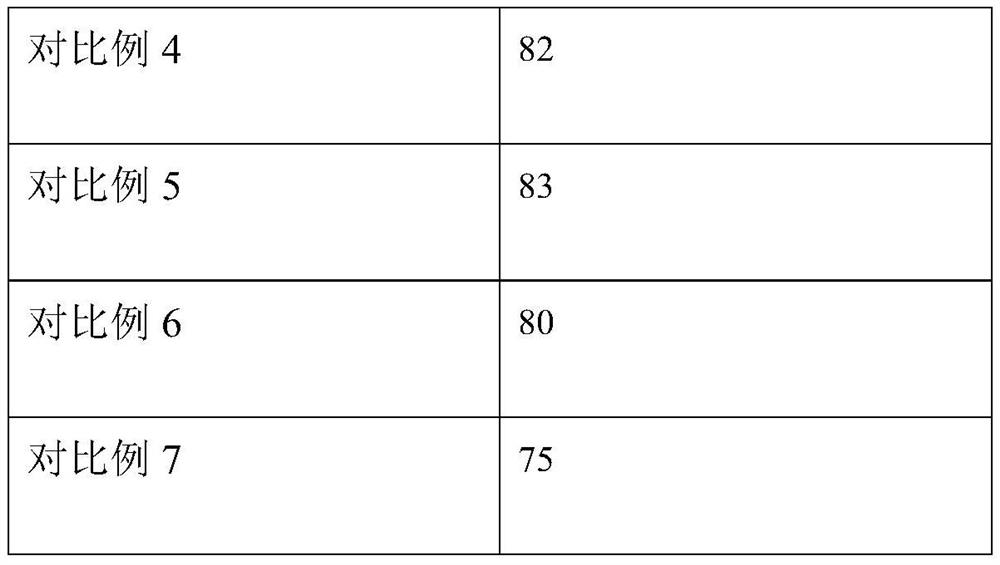

Embodiment 1

[0053] The present embodiment provides a preparation method of fermented walnut milk, the following steps:

[0054] 1) the walnut kernel of 70kg and the mass concentration of 280kg are mixed with an aqueous sodium hydroxide solution of 1.2%, stirred at 95 ° C for 6min, then the aqueous sodium hydroxide solution is discharged, and the skin is washed with pure water to obtain the peeled walnut kernel; The peeled walnut kernels were mixed with 175kg of demineralized water, and then at 78°C, the three-stage colloid mill was serially refined and then refined by Yosso mill to obtain walnut slurry. The particle size of the obtained walnut slurry was measured by Mastersizer 3000 laser particle size. The analyzer determined D V90 is 120 μm.

[0055] 2) 0.2kg of D-sodium erythorbate and 0.3kg of gellan gum and 60kg of water were mixed at 65°C with stirring and shearing at 1400r / min rotating speed for 12min to obtain the first composite stabilizer solution; 20kg of white sugar and 20kg ...

Embodiment 2

[0059] The present embodiment provides a preparation method of fermented walnut milk, the following steps:

[0060] 1) the walnut kernel of 75kg and the mass concentration of 300kg are mixed with an aqueous sodium hydroxide solution of 1.3%, stirred at 97 ° C for 5min, then the aqueous sodium hydroxide solution was discharged, and the skin was washed with pure water to obtain the peeled walnut kernel; The peeled walnut kernels were mixed with 225kg of demineralized water, and then at 78°C, the three-stage colloid mill was serially refined and then refined by Yosso mill to obtain walnut slurry. The particle size of the obtained walnut slurry was measured by Mastersizer 3000 laser particle size. The analyzer determined D V90 is 95 μm.

[0061] 2) 0.3kg of D-sodium erythorbate and 0.3kg of gellan gum and 60kg of water were mixed at 63°C with stirring and shearing at 1500r / min rotating speed for 10min to obtain the first composite stabilizer solution; 15kg of white sugar and 25kg...

Embodiment 3

[0065] The present embodiment provides a preparation method of fermented walnut milk, the following steps:

[0066] 1) the walnut kernel of 80kg and the mass concentration of 320kg are mixed with an aqueous sodium hydroxide solution of 1.1%, stirred at 97 ° C for 6min, then the aqueous sodium hydroxide solution is discharged, and the skin is washed with pure water to obtain the peeled walnut kernel; The peeled walnut kernels were mixed with 200kg of demineralized water, and then refined at 74°C with three-stage colloid mills in series and then refined by Yosso mill to obtain walnut slurry. The particle size of the obtained walnut slurry was measured by Mastersizer 3000 laser particle size The analyzer determined D V90 is 100 μm.

[0067] 2) Mix the D-sodium erythorbate of 0.25kg and the gellan gum of 0.35kg with 130kg of water at 67° C. at 1400r / min rotating speed, stirring and shearing for 13min to obtain the first composite stabilizer solution; mix 25kg of white sugar and 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com