Magnetorheological elastomer bulging device and method for non-flared pipeline connection

A magnetorheological elastomer and magnetorheological elasticity technology, applied in the field of magnetorheological elastomer bulging devices, can solve problems such as easy settlement, easy leakage, and poor overall stability, and achieve controllable performance and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

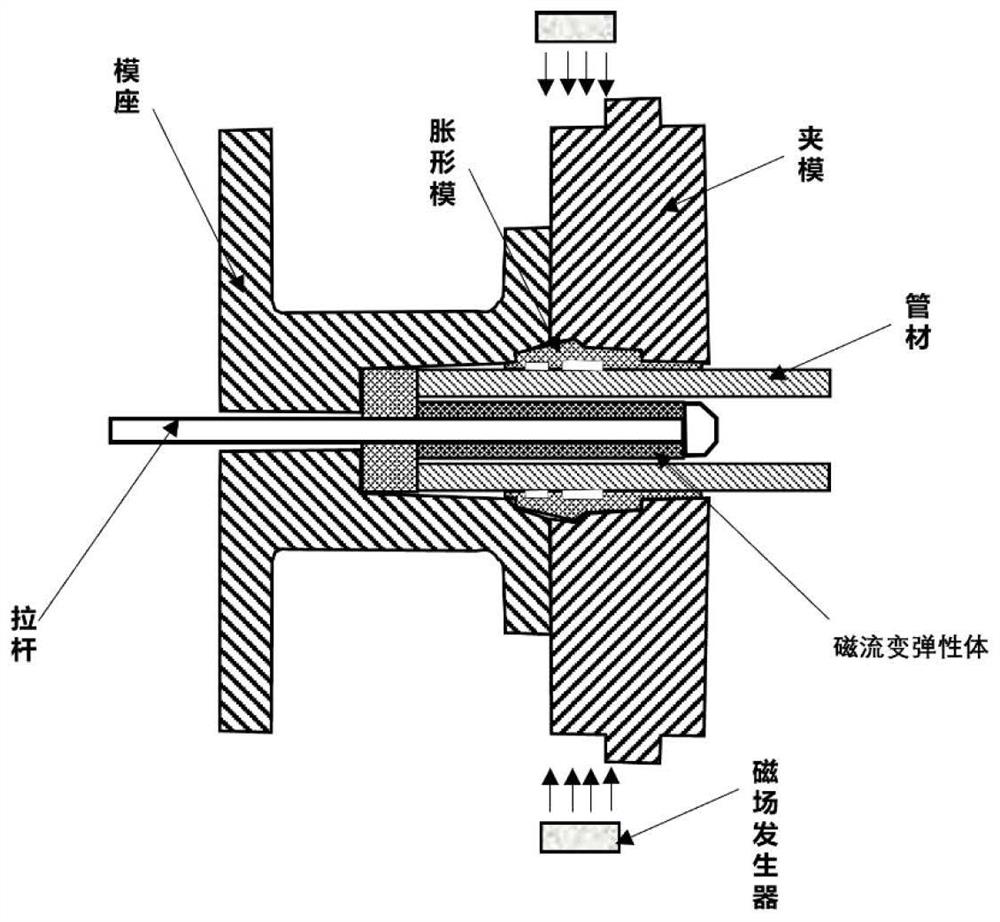

[0037] see Figure 5-Figure 7 , In the embodiment of the present invention, a magnetorheological elastomer bulging device without flaring pipeline connection includes a base 11 and a transmission component arranged at its upper end for transmitting the metal pipe 26 to be expanded. The transmission component It includes two parallel transmission rollers 13, a transmission belt 21 for transmission is wound between the two transmission rollers 13, and an anti-skid layer 20 is distributed on the surface of the transmission belt 21. The fixed shaft end of the transmission roller 13 passes through the support. The legs are connected and fixed to the base 11 , and the fixed shaft end of one of the transmission rollers 13 is connected to the transmission motor 12 for driving the rotation of the transmission roller 13 . The surface of the transmission belt 21 is distributed with a number of buffer fixing grooves 19 arranged at equal intervals. The buffer fixing groove 19 is used to pl...

Embodiment 2

[0043] see Figure 1-Figure 4 , a magnetorheological elastomer bulging method for pipe connection without flare is as follows:

[0044] The first step is to use GH4169 nickel-based superalloy as the metal pipe, and select GH4169 nickel-based superalloy with a wall thickness of 0.8mm and a pipe diameter of Φ16mm for use;

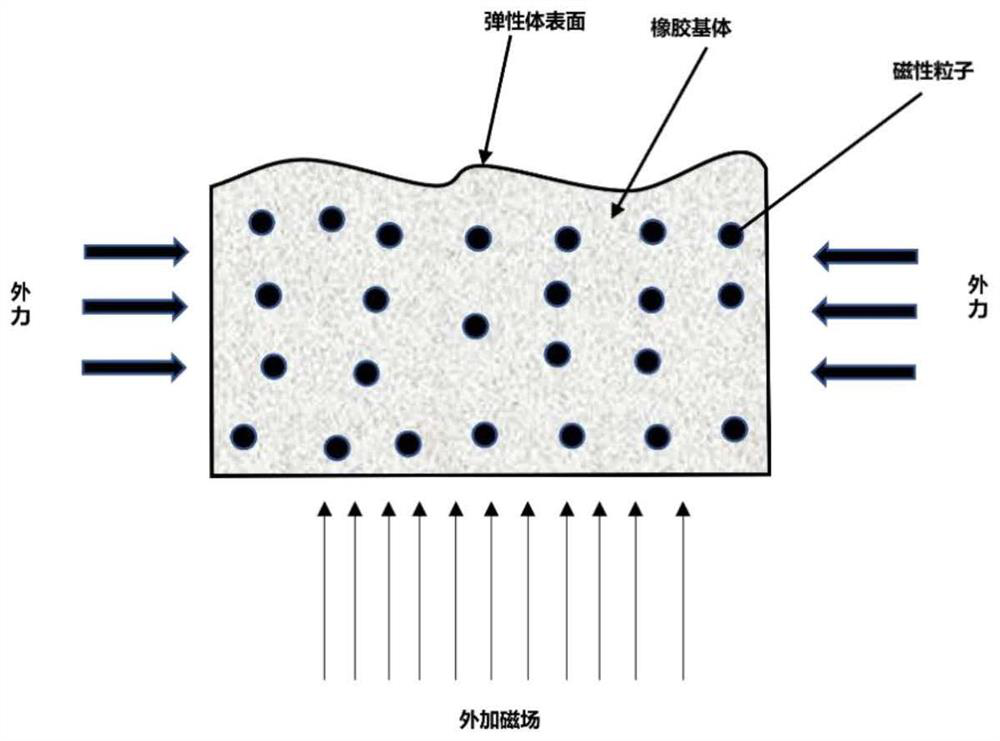

[0045] In the second step, silicon and catalyst were added in a mass ratio of 100:10 and stirred uniformly. After that, add 25% dimethyl silicone oil by mass fraction. After stirring evenly, add carbonyl iron powder with a mass fraction of 50% and stir well. After the above steps are completed, the liquid MR mixture is poured into the mold, placed in a heat transfer section preheated to 70° C. for curing, and a magnetorheological elastic rubber sleeve is made in the form of a hollow cylinder.

[0046] In the third step, AISI 316 stainless steel is used as the bulging die, that is, as the pipe sleeve. Use 1-6 metallographic sandpaper to polish the surface ...

Embodiment 3

[0050] see Figure 1-Figure 4 , a magnetorheological elastomer bulging method for pipe connection without flare of the present invention is as follows:

[0051] The first step is to use 6061 aluminum alloy as the metal pipe, and select 6061 aluminum alloy with a wall thickness of 1mm and a pipe diameter of Φ15mm for use;

[0052] In the second step, silicon and catalyst were added in a mass ratio of 100:10 and stirred uniformly. After that, add 25% dimethyl silicone oil by mass fraction. After stirring evenly, add carbonyl iron powder with a mass fraction of 50% and stir well. After the above steps are completed, the liquid MR mixture is poured into the mold, placed in a heat transfer section preheated to 70° C. for curing, and a magnetorheological elastic rubber sleeve is made in the form of a hollow cylinder.

[0053] The third step is to use YG8 tungsten steel alloy as the bulging die, that is, as the tube sleeve. Use 1-6 metallographic sandpaper to polish the surface o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com