Preparation method of ceramic particle reinforced refractory high-entropy alloy

A high-entropy alloy, ceramic particle technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of low process efficiency, complex process flow, low powder yield, etc., and achieve simple process flow, low cost, ball milling, etc. short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

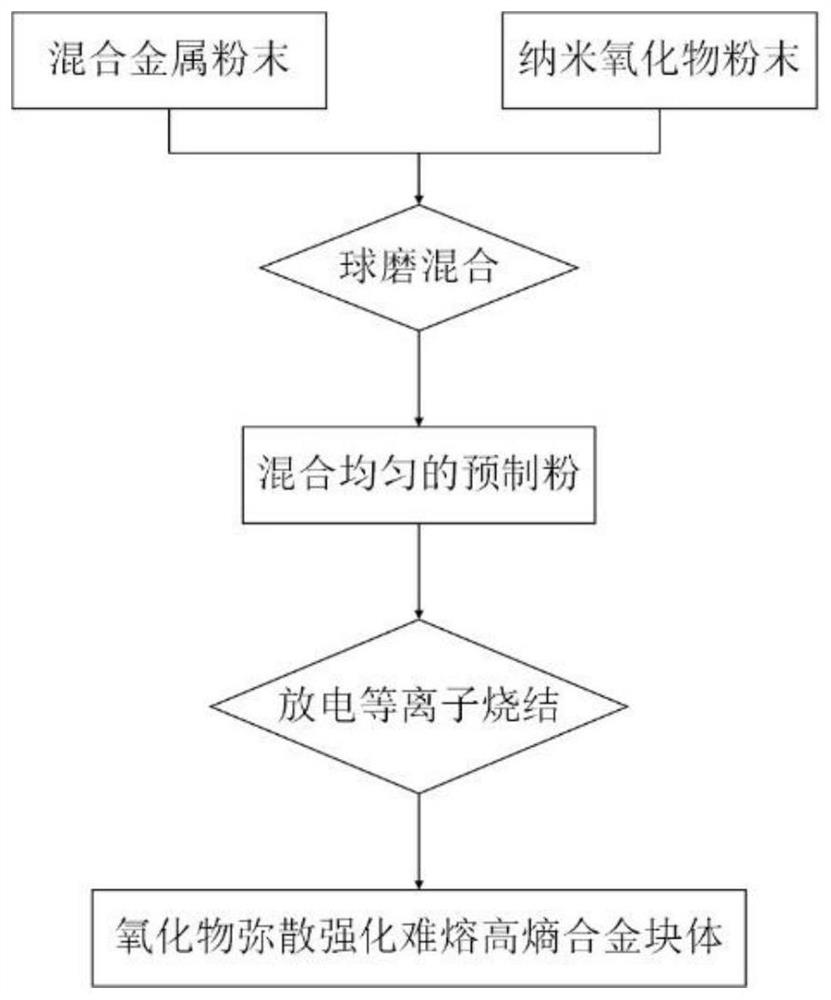

Method used

Image

Examples

Embodiment 1

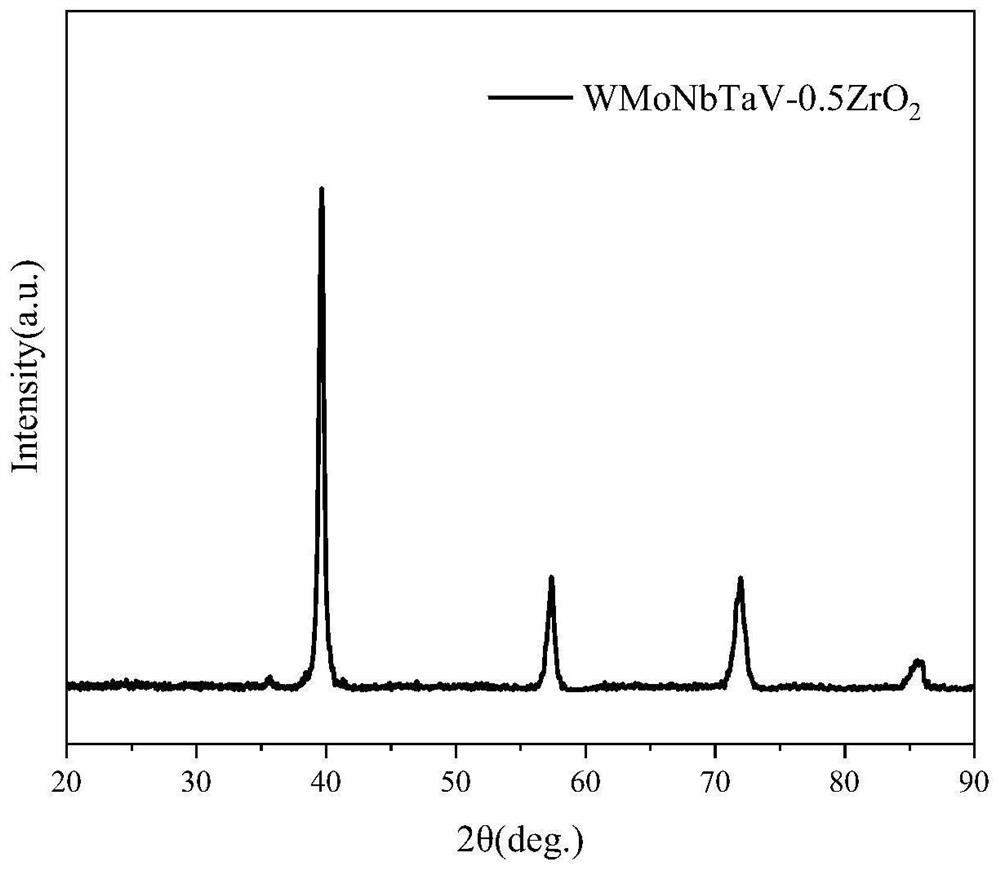

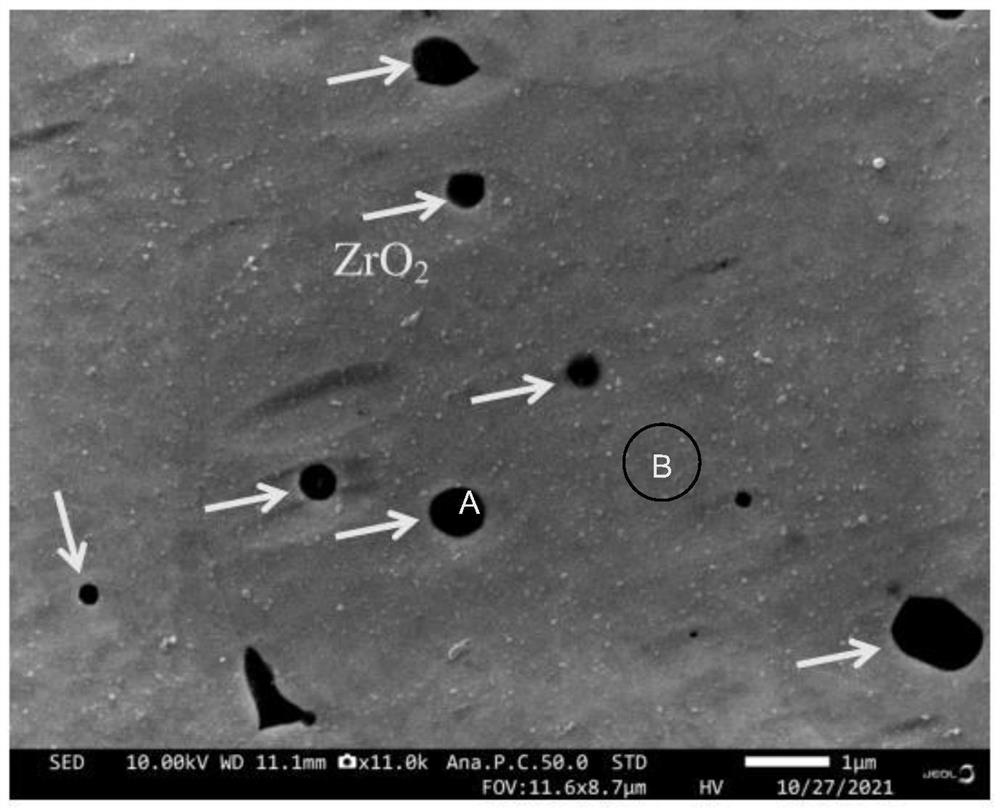

[0028] (1) Ball milling mixing: 99.5 g of metal powder and nano-ZrO mixed with equal molar ratios of W powder, Mo powder, Nb powder, Ta powder and V powder are used 2 0.5g of particles was used as a raw material, without adding a ball milling medium, ball milling and mixing were carried out in a planetary ball mill. Among them, the particle size of W powder and Ta powder are both less than 0.035mm, the particle size of Mo powder and Nb are less than 0.045mm, and the particle size of nano ZrO 2 The particle size is less than 30nm; the purity of W powder, Mo powder, Nb powder, Ta powder and V powder are all greater than 99.9%, nano ZrO 2 The purity is greater than 99.99%. The material of the ball mill jar and the grinding balls are WC cemented carbide. The inside of the ball mill jar is evacuated and high-purity argon gas is introduced as a protective atmosphere. In the process of ball milling, the ball-to-material ratio is 10:1, the ball milling speed is 300r / min, the operati...

Embodiment 2

[0032] (1) Ball milling mixing: 99g of metal powder and nano ZrO mixed with equal molar ratio of W powder, Mo powder, Nb powder, Ta powder and V powder are used 2 1 g of particles was used as a raw material, and ball milling was carried out in a planetary ball mill without adding a ball milling medium. The particle size of W powder and Ta powder are all less than 0.035mm, the particle size of Mo powder, Nb powder and V powder are all less than 0.045mm, and the particle size of nano ZrO powder is less than 0.045mm. 2 The particle size is less than 30nm; the purity of W powder, Mo powder, Nb powder, Ta powder and V powder are all greater than 99.9%, nano ZrO 2 The purity is greater than 99.99%. The material of the ball mill jar and the grinding balls are WC cemented carbide. The inside of the ball mill jar is evacuated and high-purity argon gas is introduced as a protective atmosphere. In the process of ball milling, the ball-to-material ratio is 12:1, the ball milling speed i...

Embodiment 3

[0037] (1) Ball milling mixing: 99g of metal powder and nano ZrO mixed with equal molar ratio of W powder, Mo powder, Nb powder, Ta powder and V powder are used 2 1 g of particles was used as a raw material, and ball milling was carried out in a planetary ball mill without adding a ball milling medium. The particle size of W powder and Ta powder are all less than 0.035mm, the particle size of Mo powder, Nb powder and V powder are all less than 0.045mm, and the particle size of nano ZrO powder is less than 0.045mm. 2 The particle size of the powder is less than 30nm; the purity of W powder, Mo powder, Nb powder, Ta powder and V powder are all greater than 99.9%, and nano ZrO powder 2 The purity is greater than 99.99%. The material of the ball mill jar and the grinding balls are WC cemented carbide. The inside of the ball mill jar is evacuated and high-purity argon gas is introduced as a protective atmosphere. In the process of ball milling, the ball-to-material ratio is 15:1,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com