Dry granule, dry granule glaze, high-hardness and high-wear-resistance rock plate and preparation method thereof

A high-hardness, high-wear-resistant technology, applied in the field of ceramic slate, can solve the problem that the glaze hardness and wear resistance of porcelain slate are not further improved, and achieve enhanced hardness and wear resistance, simple steps, and reduced sintering temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

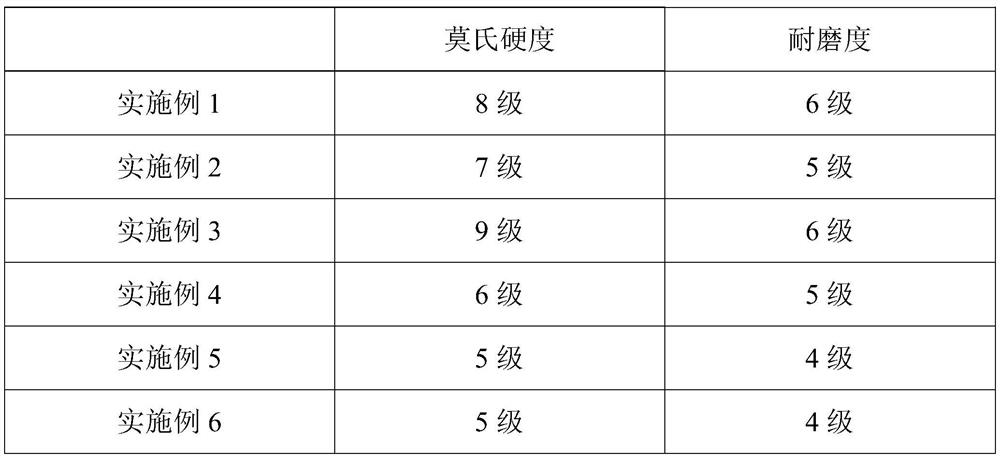

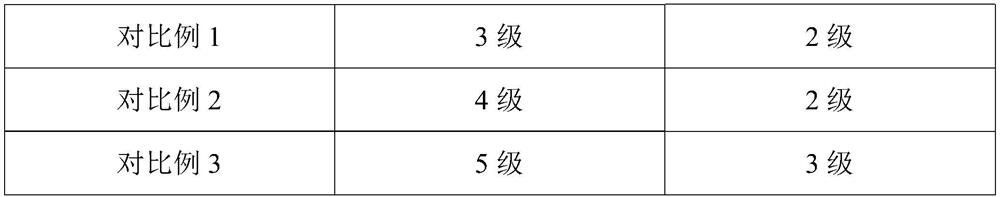

Examples

Embodiment 1

[0033] The dry particles provided in this embodiment include the following raw materials by mass: 20% potassium feldspar, 10% quartz, 10% calcite, 10% barium carbonate, 20% zinc oxide, 2% α-Al 2 O 3 The particle size of nano powder, 8% nano silicon dioxide, 20% chitosan, α-Al2O3 nano powder is 1 nm, and the particle size of the prepared dry particles is 120 meshes.

Embodiment 2

[0035] The dry particles provided in this example include the following raw materials by mass: 35% potassium feldspar, 15% quartz, 15% calcite, 5% barium carbonate, 8% zinc oxide, 1% α-Al 2 O 3 Nano powder, 6% nano silica, 15% chitosan, α-Al 2 O 3 The particle size of the nano powder is 4 nm, and the particle size of the prepared dry particles is 120 meshes.

Embodiment 3

[0037] The dry particles provided in this embodiment include the following raw materials by mass: 5% potassium feldspar, 10% quartz, 25% calcite, 15% barium carbonate, 5% zinc oxide, 1.5% α-Al 2 O 3 Nano powder, 15% nano silica, 23.5% chitosan, α-Al 2 O 3 The particle size of the nano powder is 3 nm, and the particle size of the prepared dry particles is 200 meshes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com