Patents

Literature

38results about How to "Suitable for industrial large-scale preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

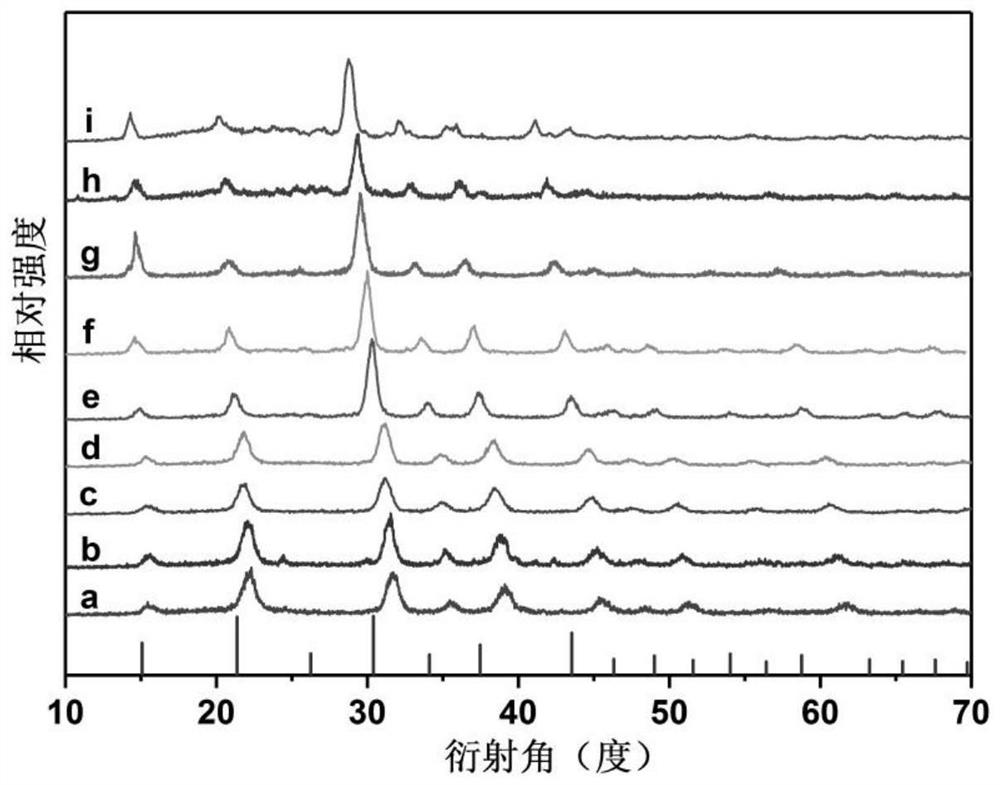

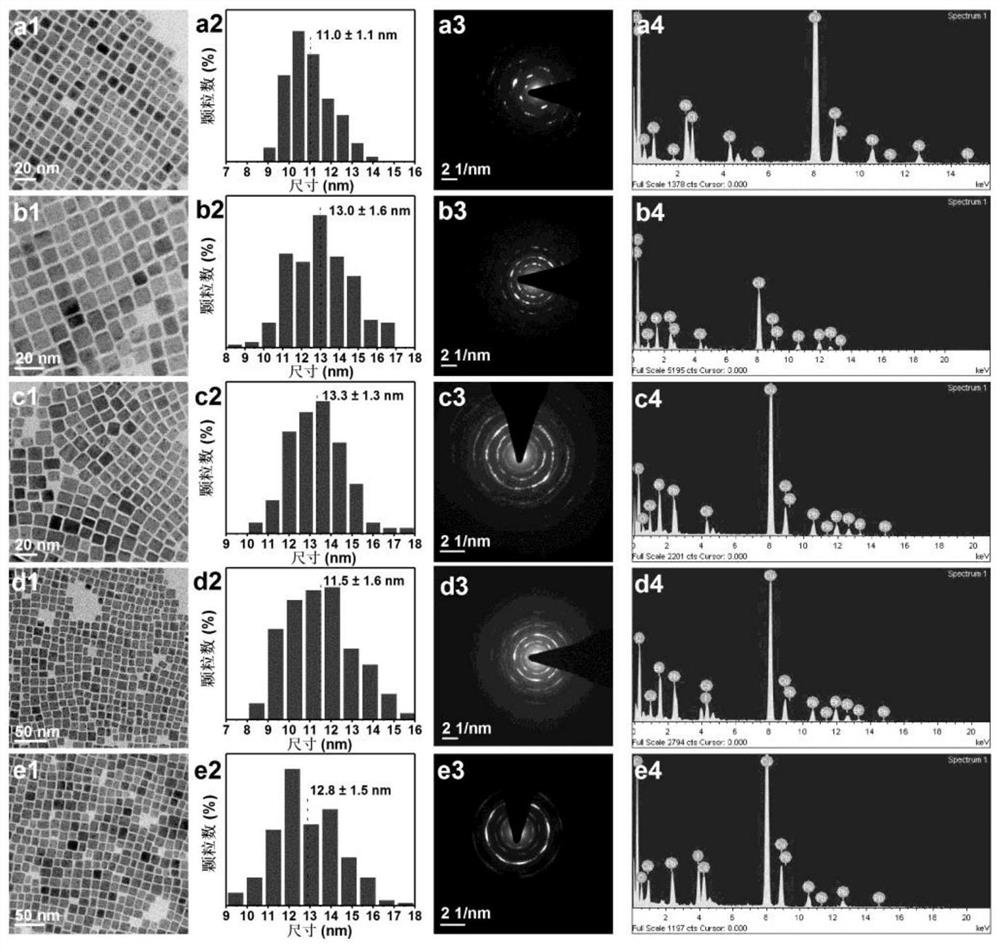

Preparation method of abx3 type all-inorganic perovskite nanocrystal

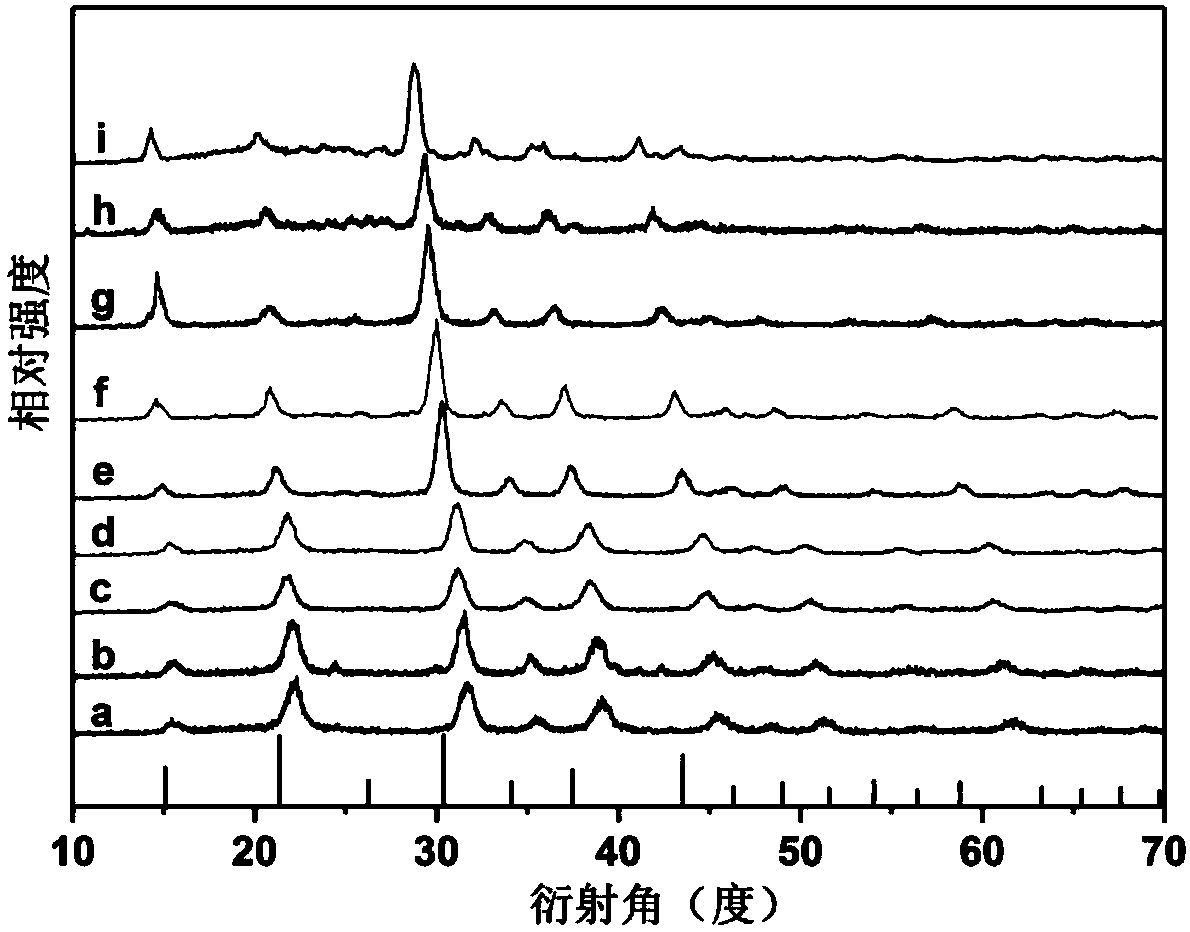

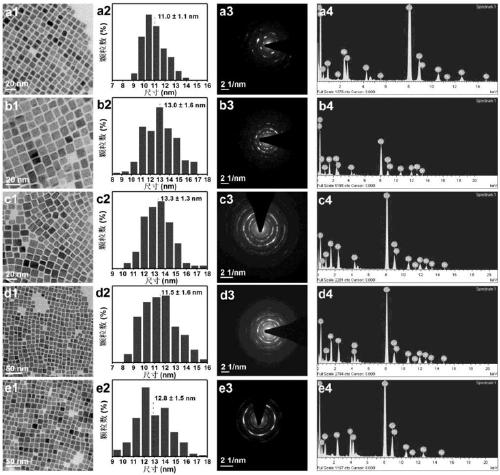

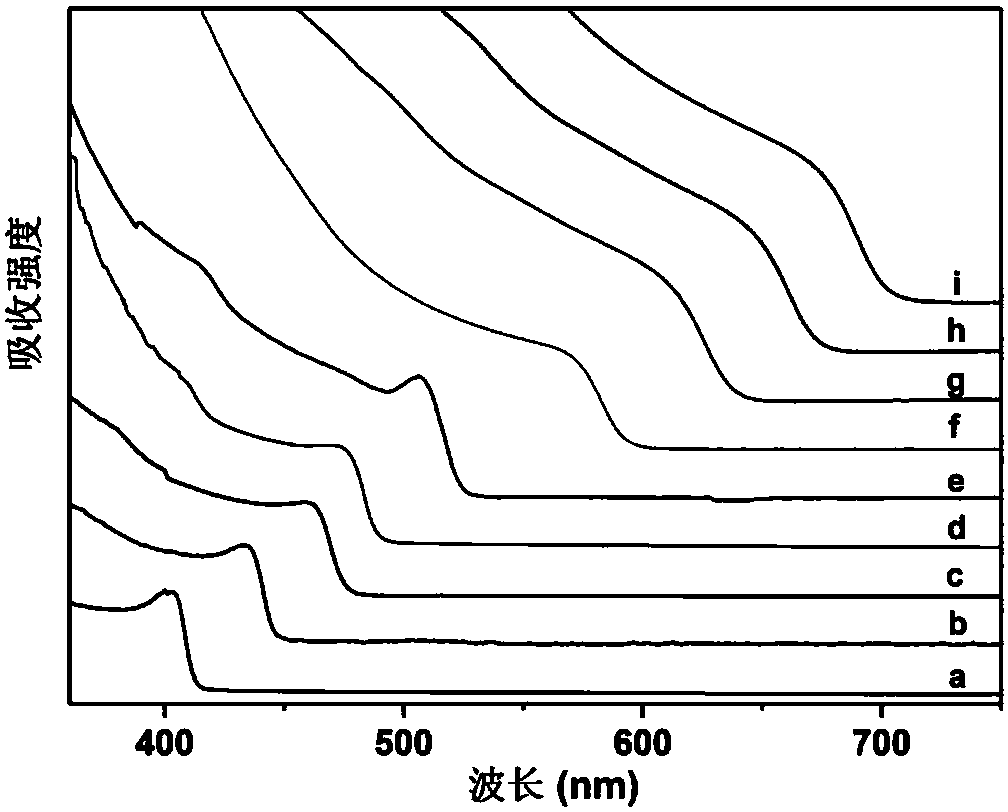

The invention discloses a preparation method of an ABX3 type all-inorganic perovskite nanocrystal. In the preparation process, a solvent is used in a small amount, and the raw material unit price is low (for example, an expensive PbX2 raw material is replaced by cheap lead acetate), environmental requirements are not high in the preparation process, a glove box is not required, the operation procedure is simple, and the cost of raw materials and instruments is greatly reduced. The nanocrystal can synthesize a target product in a wide temperature range of 0 to 300 DEG C in the preparation process, and the morphology, phase, size and luminous performance of the nanocrystal can be controlled by changing the raw material ratio, solvent ratio, reaction temperature and / or reaction time, for example, perovskite nanowires can be prepared at the reaction temperature of greater than or equal to 0 DEG C and less than 90 DEG C, and perovskite quantum dots can be prepared at the reaction temperature of 90 to 300 DEG C. The nanocrystal has good stability and high fluorescence quantum yield (26%-80%), and can realize full visible spectrum (400-700 nm) luminescence. The preparation method is simple in process, short in time consumption, low in cost, easy to amplify and synthesize, and suitable for industrial large-scale preparation.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

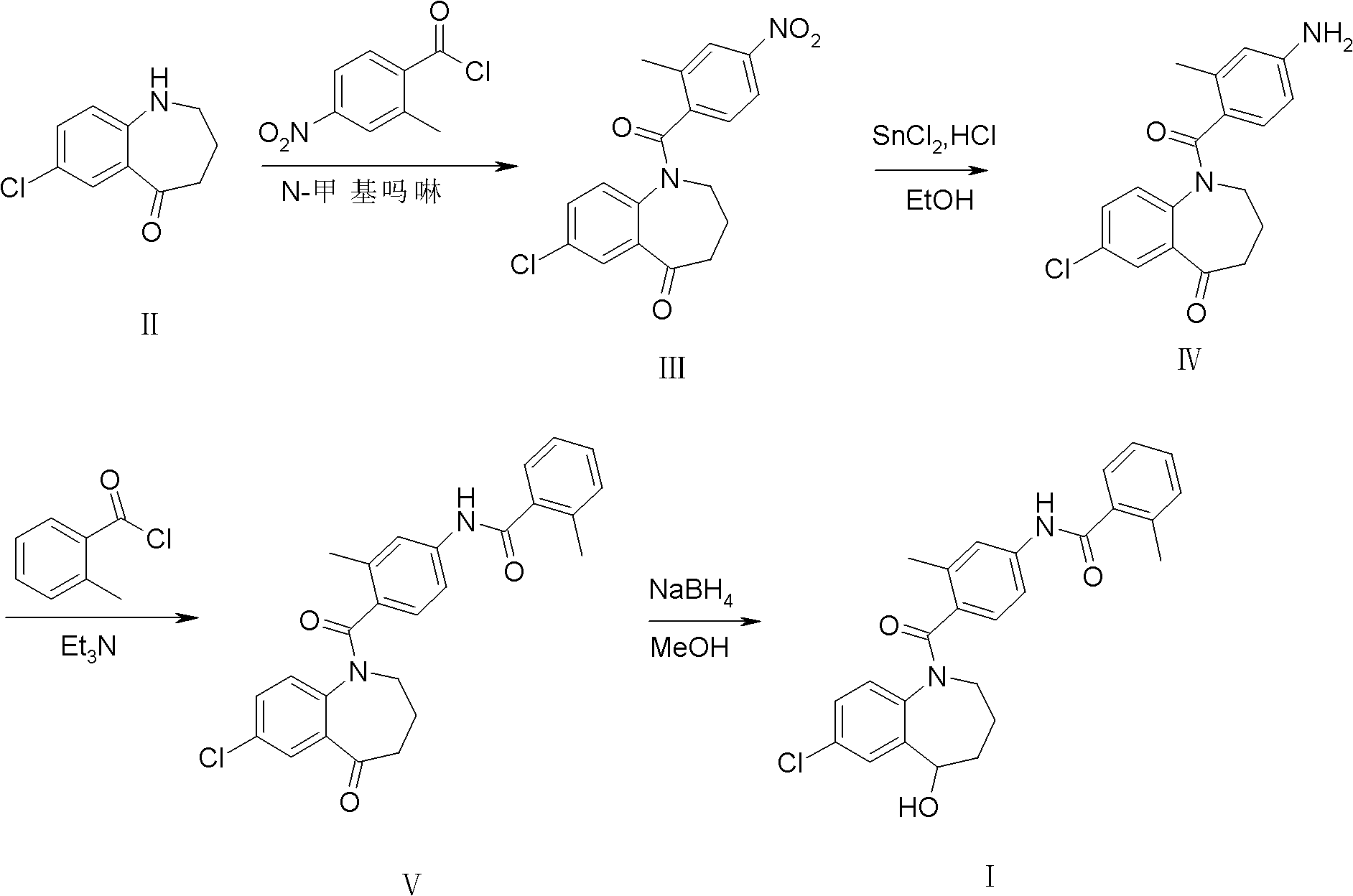

Preparation method of tolvaptan

The invention relates to a preparation method of tolvaptan as an arginine vessel pitressin V2 receptor antagonist. The tolvaptan and the intermediate thereof with high purity and efficiency can be obtained with the preparation method which can be used as an industrial method for mass production. Meanwhile, the invention has the advantages of reducing the emission of waste liquid, being favorable to labor protection, decreasing the production cost and improving the economic benefits.

Owner:TIANJIN INSTITUTE OF PHARMA RESEARCH

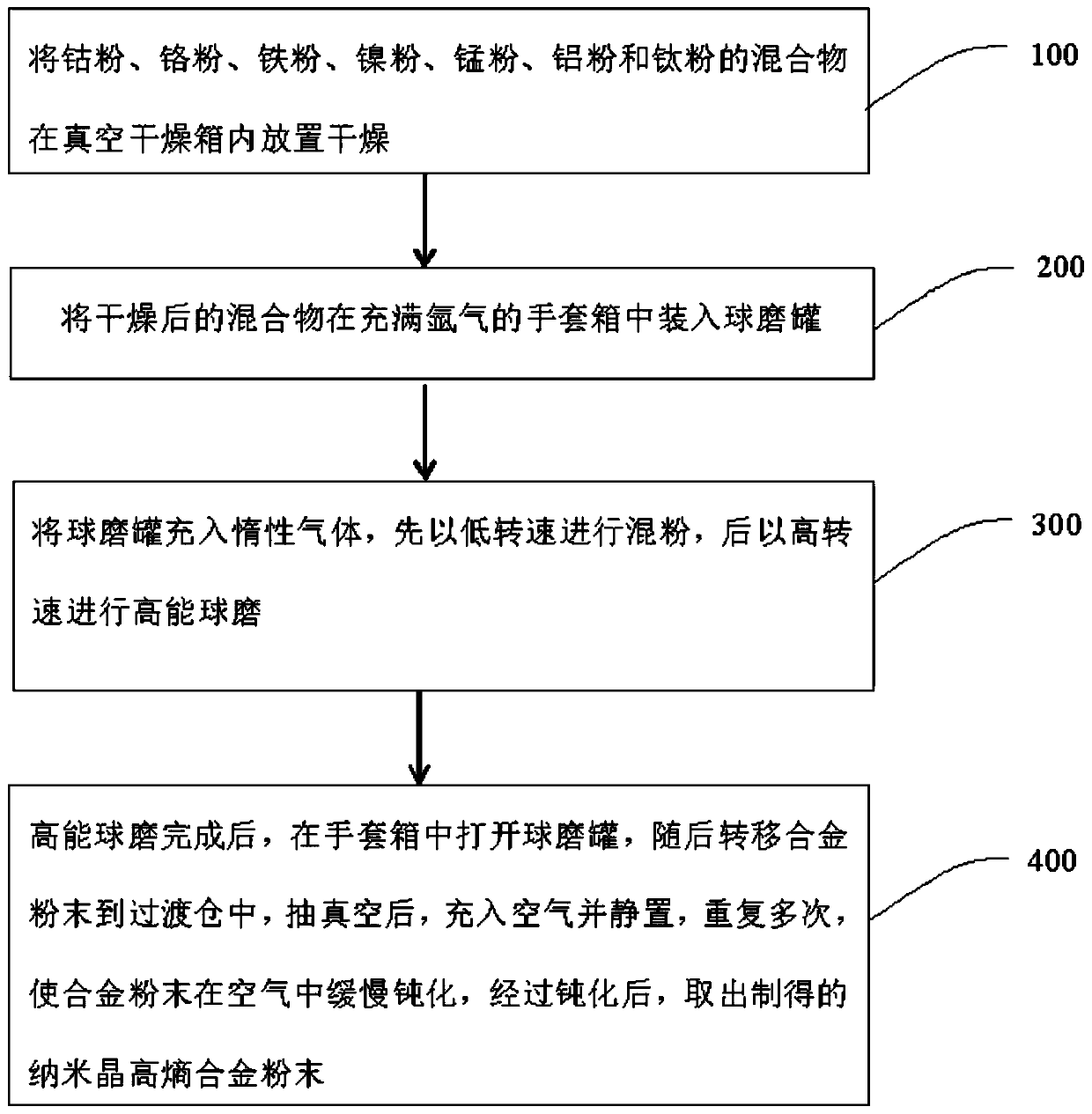

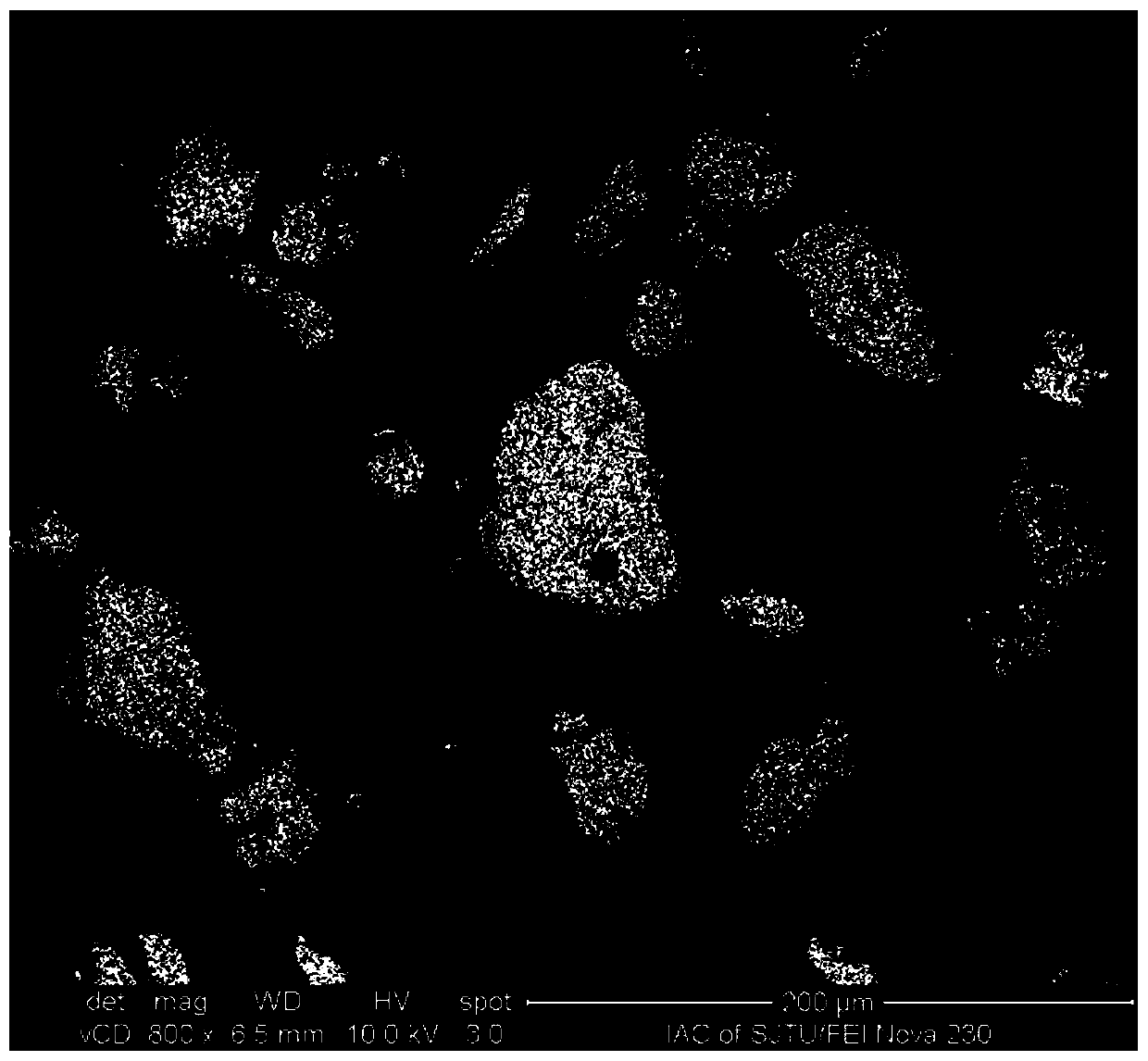

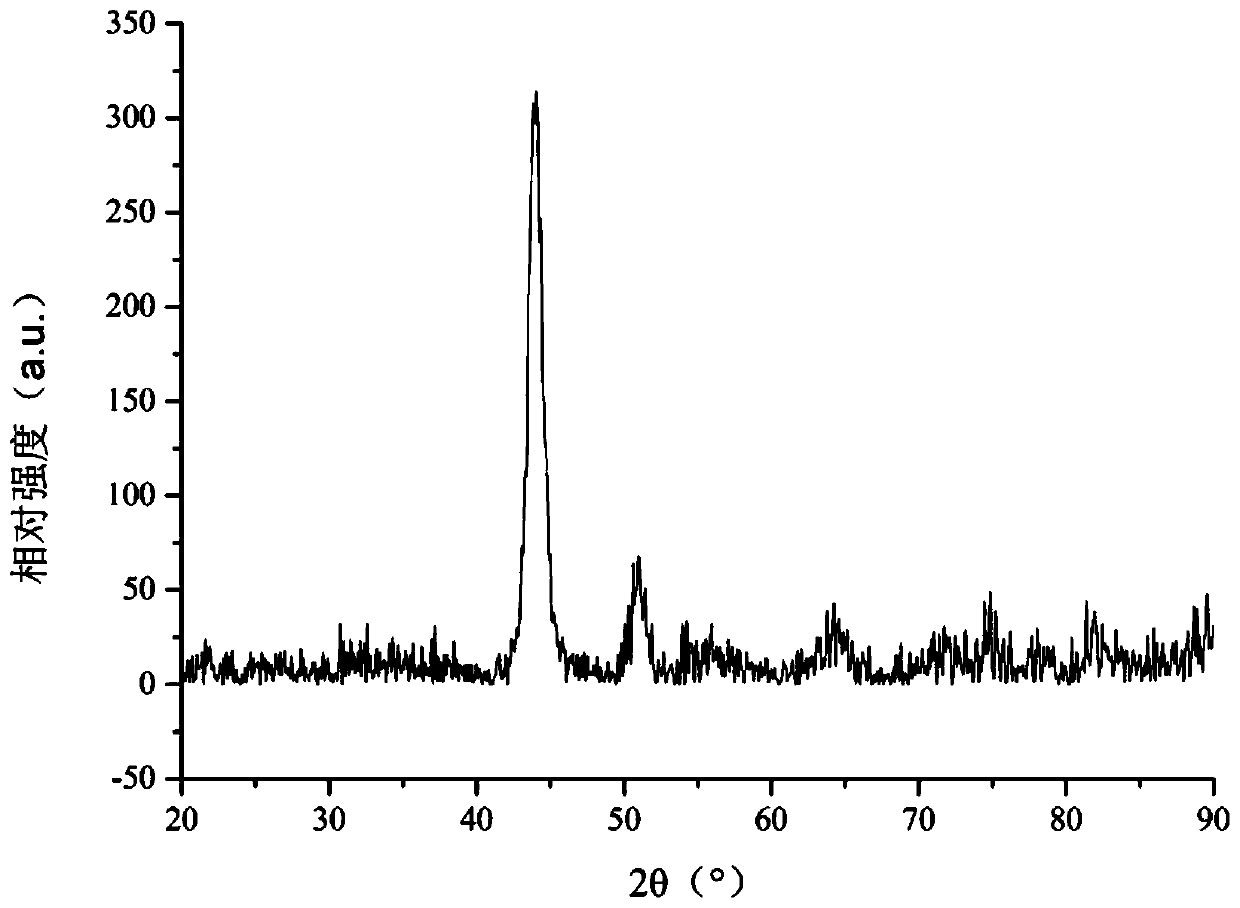

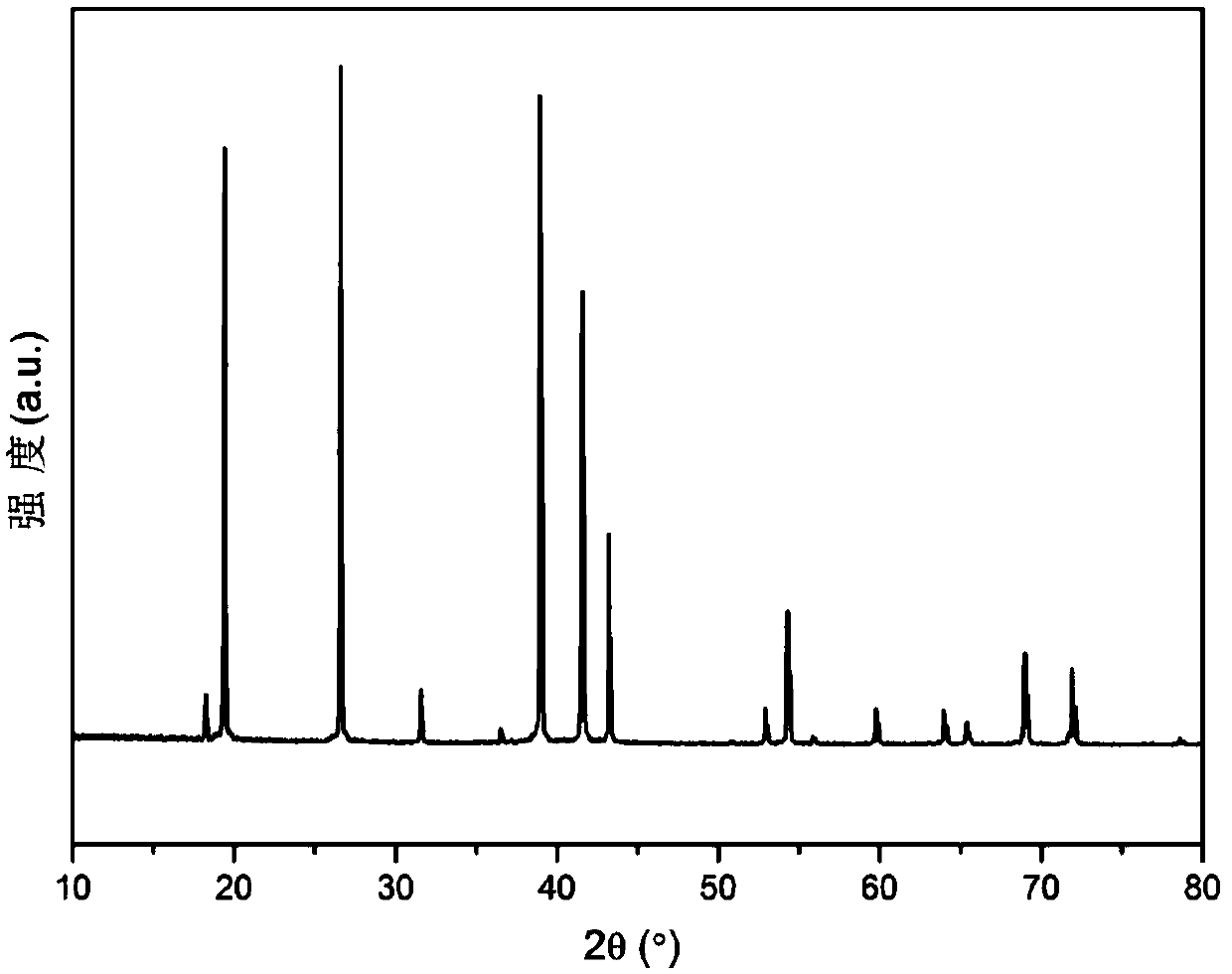

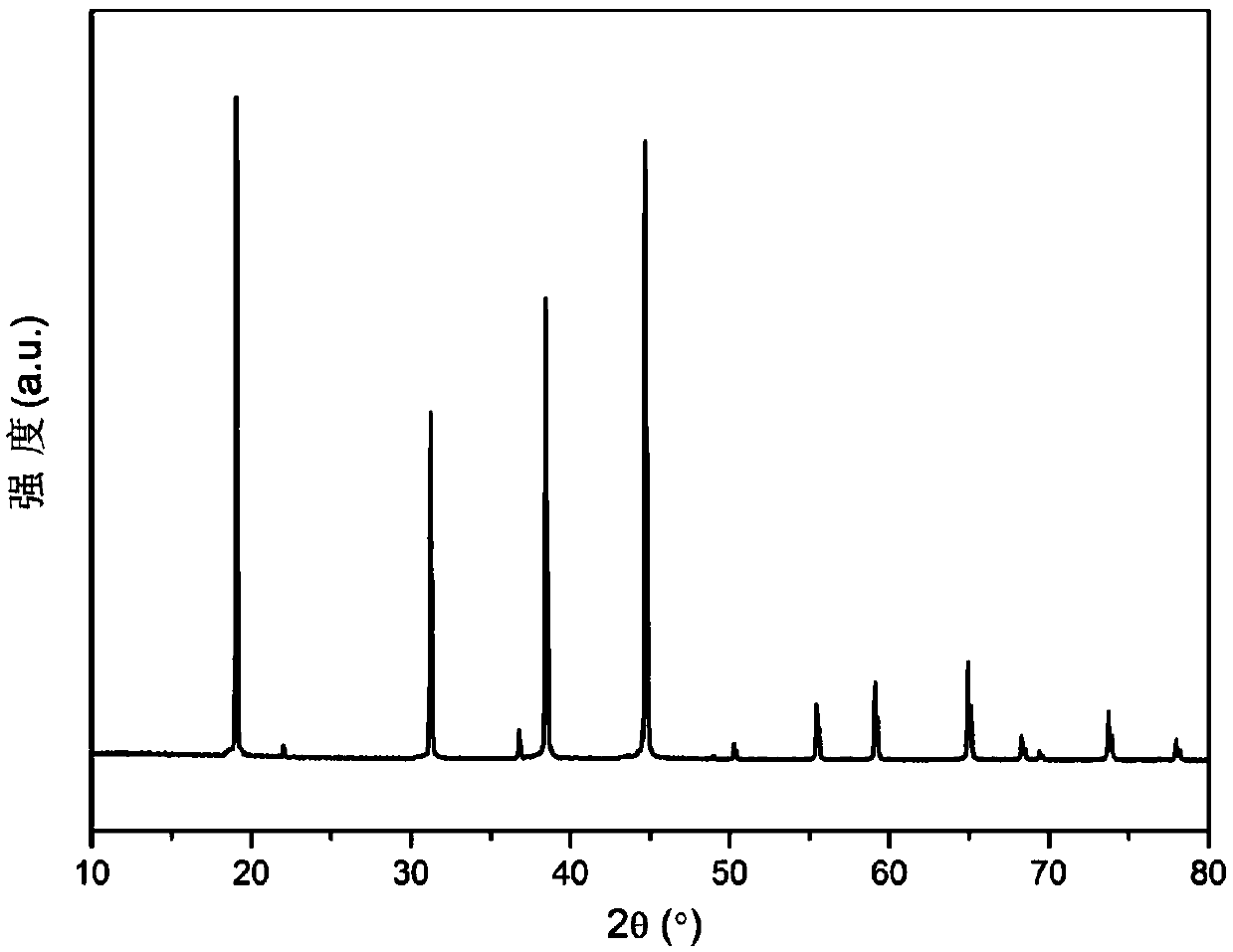

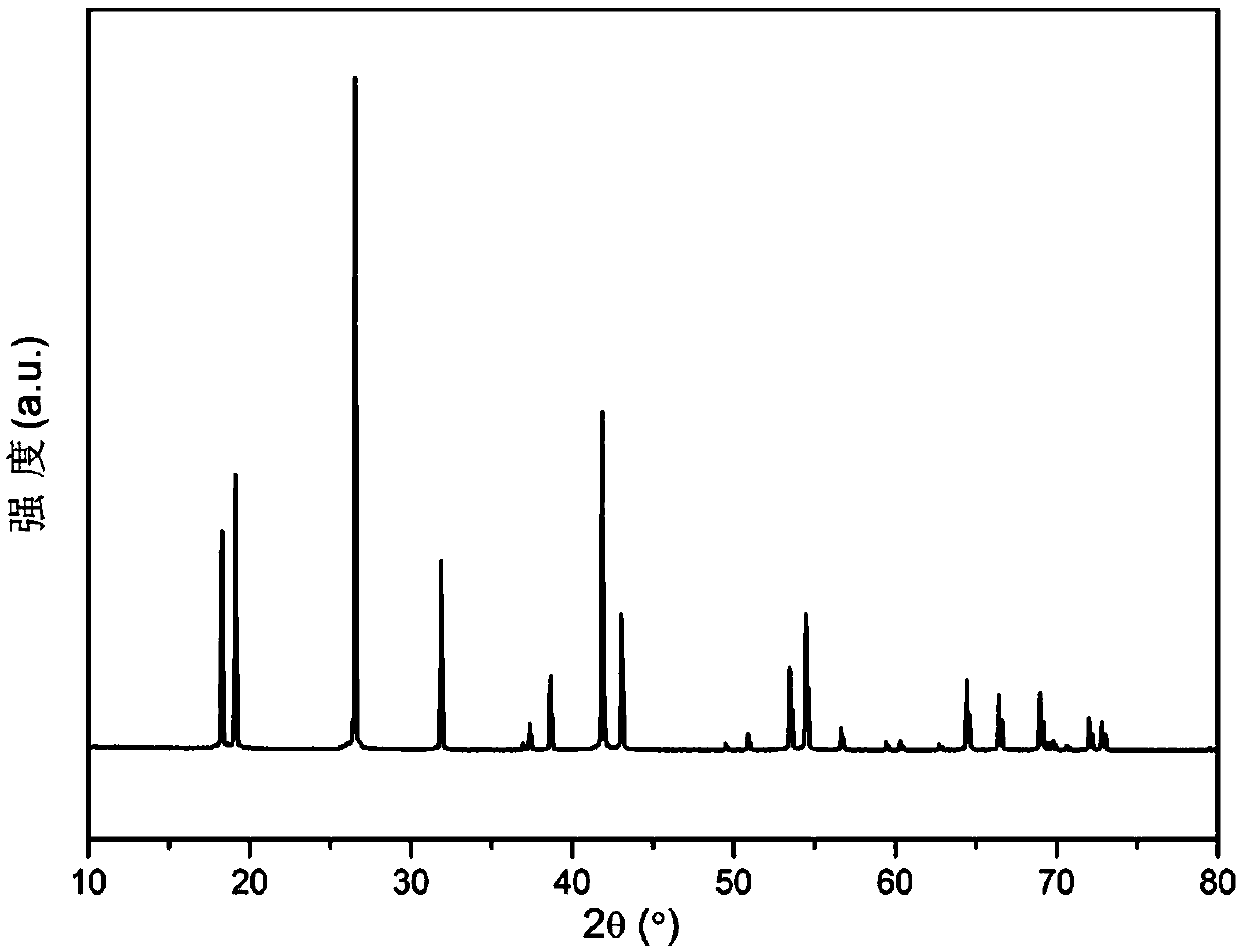

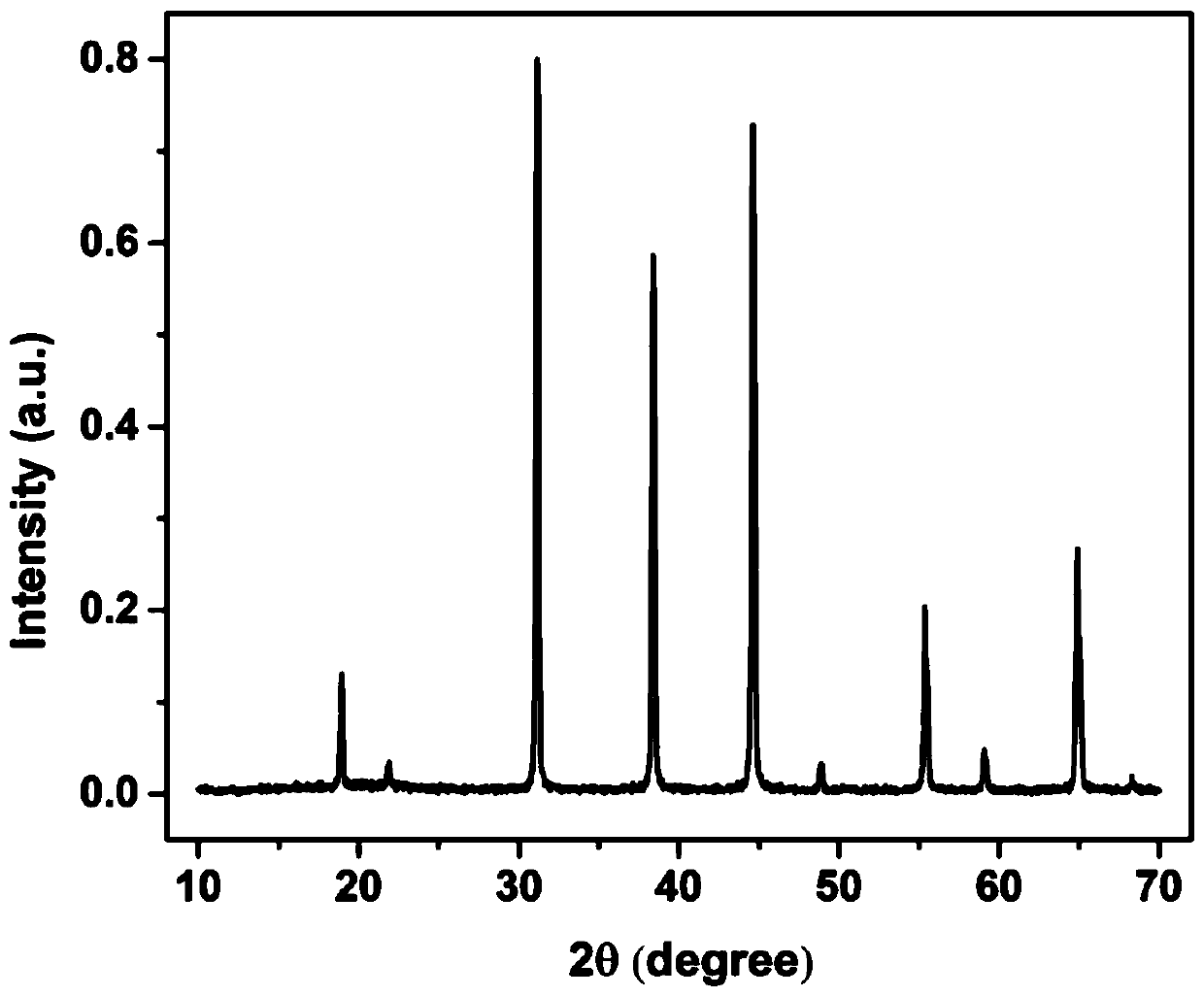

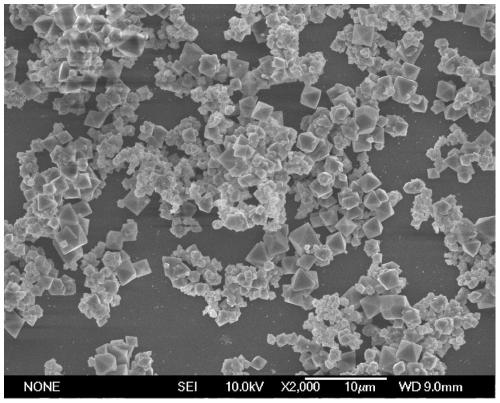

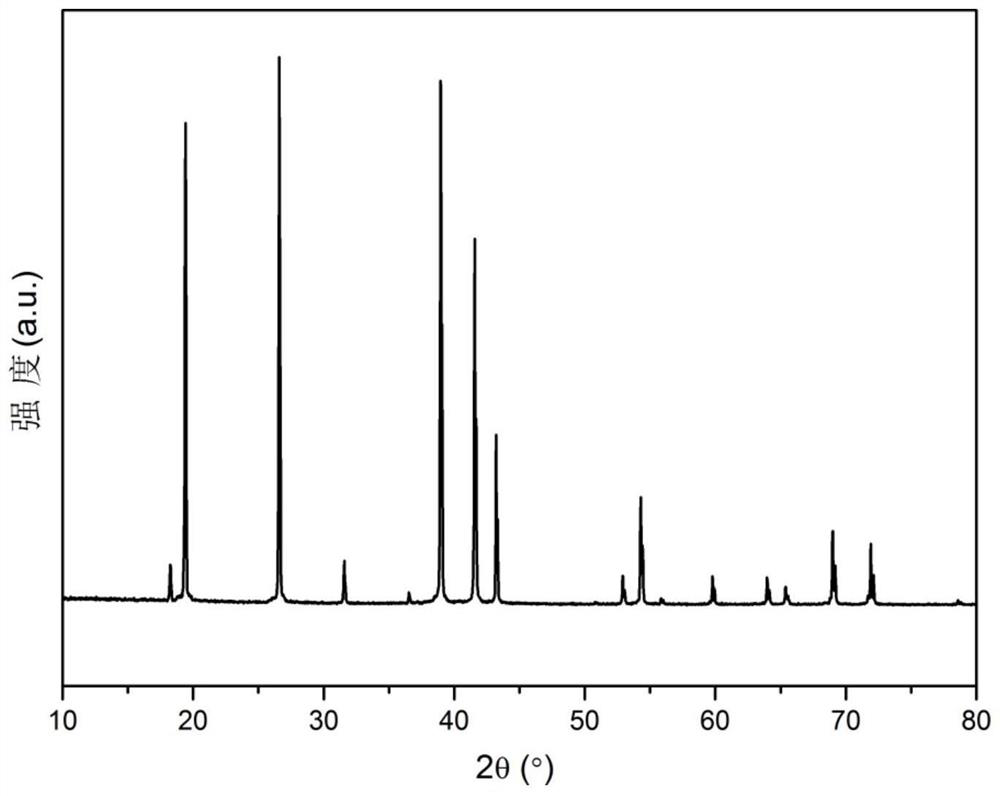

Nanocrystalline high-entropy alloy powder and preparation method thereof

InactiveCN110576185AOvercome high energy consumptionLower the activation energy of the reactionHigh entropy alloysPowder metallurgy

The invention discloses nanocrystalline high-entropy alloy powder and a preparation method thereof, and relates to the technical field of powder metallurgy. The invention involves the nanocrystallinehigh-entropy alloy powder and the preparation method of the nanocrystalline high-entropy alloy powder, wherein the nanocrystalline high-entropy alloy powder comprises cobalt powder, chromium powder, iron powder, nickel powder, manganese powder, aluminum powder and titanium powder; and the metal element powder is directly mixed through a high-energy mechanical ball milling method by the preparationmethod of the nanocrystalline high-entropy alloy powder, and the nanocrystalline high-entropy alloy powder is prepared according to the specific steps. According to the nanocrystalline high-entropy alloy powder and the preparation method, through high-speed impact and grinding of grinding medium, reaction activation energy is reduced, powder activity is improved, solid diffusion among element powder is promoted, low-temperature chemical reaction is induced, and finally, the alloy powder with uniform composition and structure distribution is obtained, so that the problems of element volatilization and non-uniform components of the powdering after smelting is conducted are solved. The technical is simple in equipment, the procedure is simplified compared with a traditional method, the manufacturing cost is reduced, and the nanocrystalline high-entropy alloy powder powder the preparation method thereof are suitable for industrial large-scale preparation.

Owner:SHANGHAI JIAO TONG UNIV

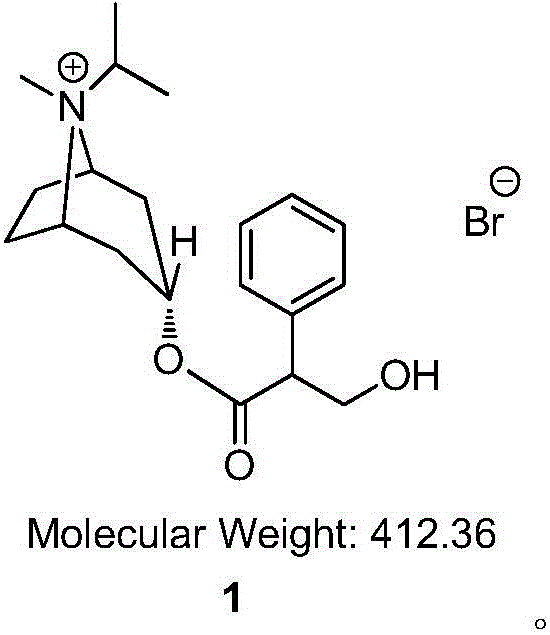

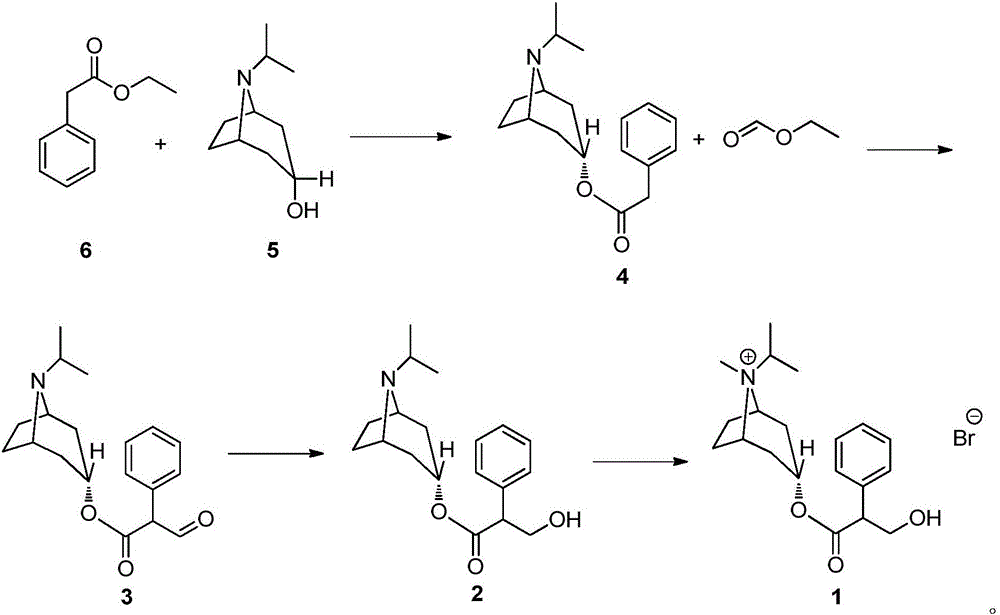

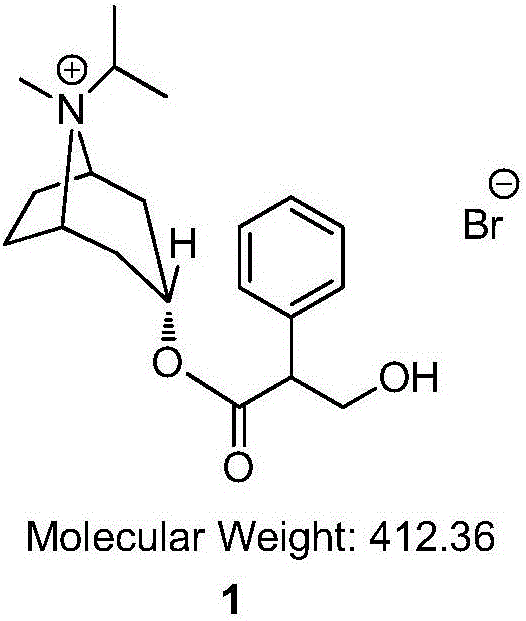

Preparation method of ipratropium bromide

The invention relates to a preparation method of an M-choline receptor blocking agent of ipratropium bromide 1. The preparation method comprises the following steps of using ethyl phenylacetate as starting raw materials; performing reaction with isopropyl tropanol; generating phenylacetate isopropyl tropeine; then, performing substitution, reduction and addition reaction to obtain the ipratropium bromide. The method has the advantages that the operation is simple; safety and controllability are realized; the work protection is low; the preparation method is suitable for industrial production. The formula is shown as the accompanying drawing, and the molecular weight is 412.36.

Owner:SHANDONG ACADEMY OF PHARMACEUTICAL SCIENCES +1

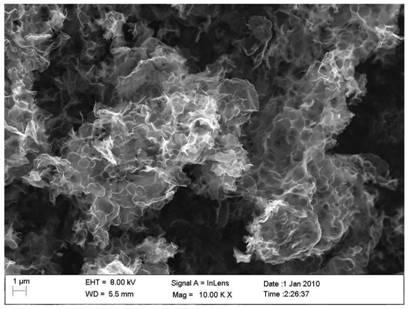

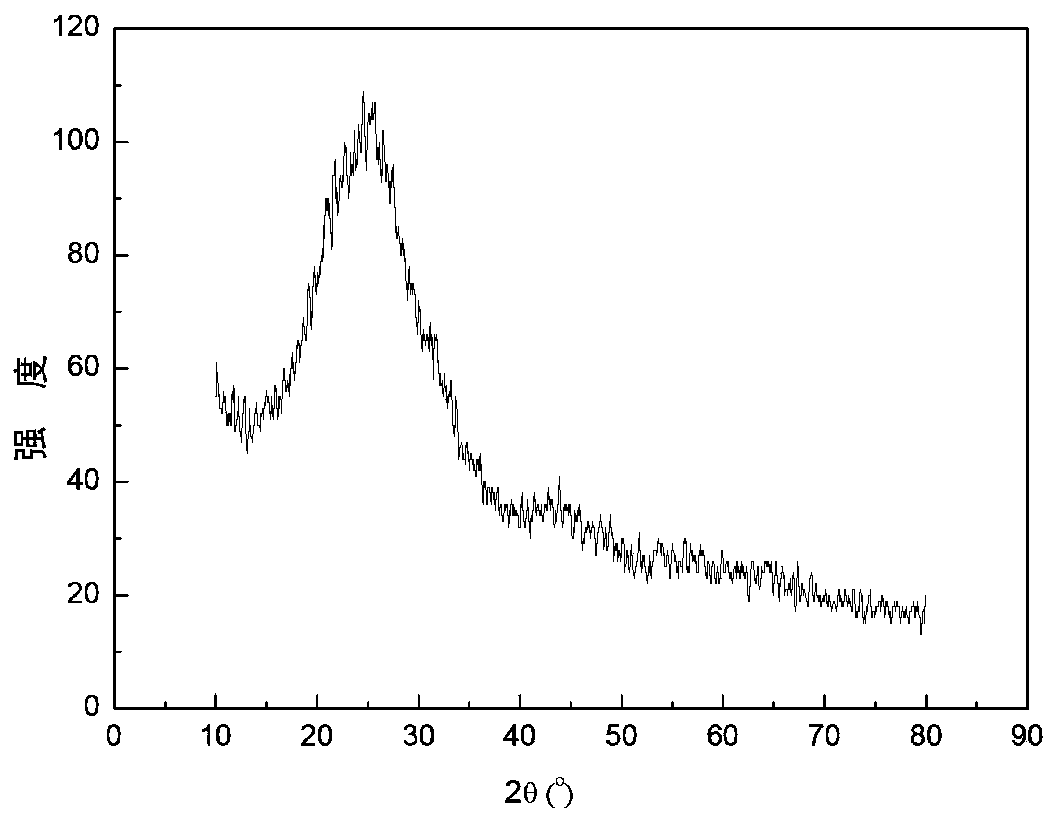

Preparation method of carbon nitride ultrathin sheet with adjustable atom layer number

ActiveCN107324297AImprove electrocatalytic activityFast preparationMaterial nanotechnologyPhysical/chemical process catalystsOrganic solventFree cooling

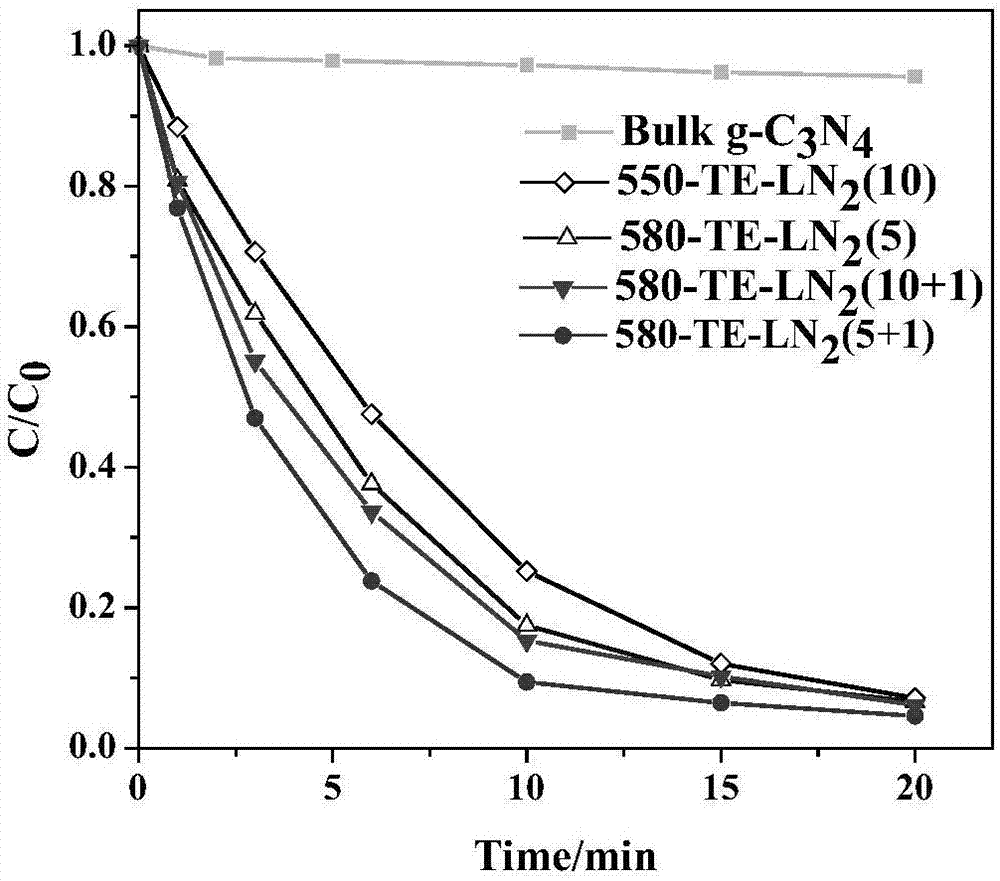

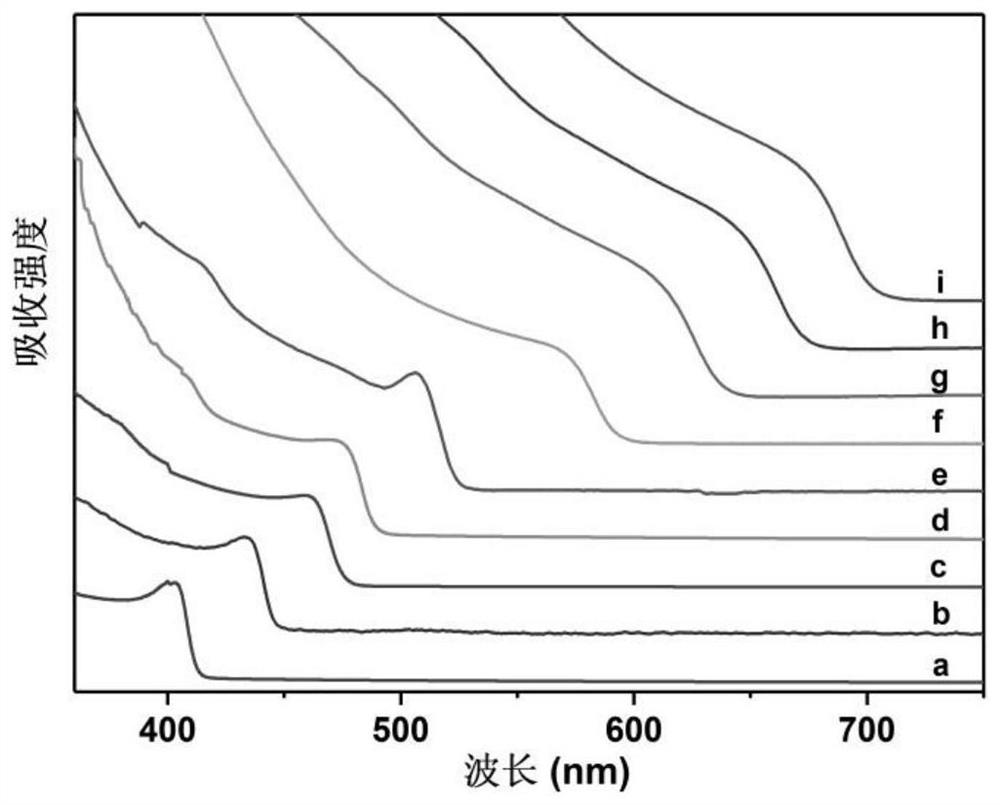

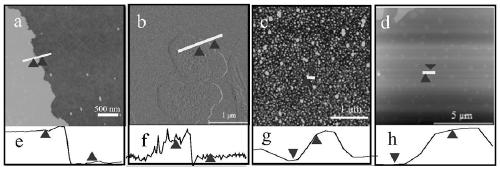

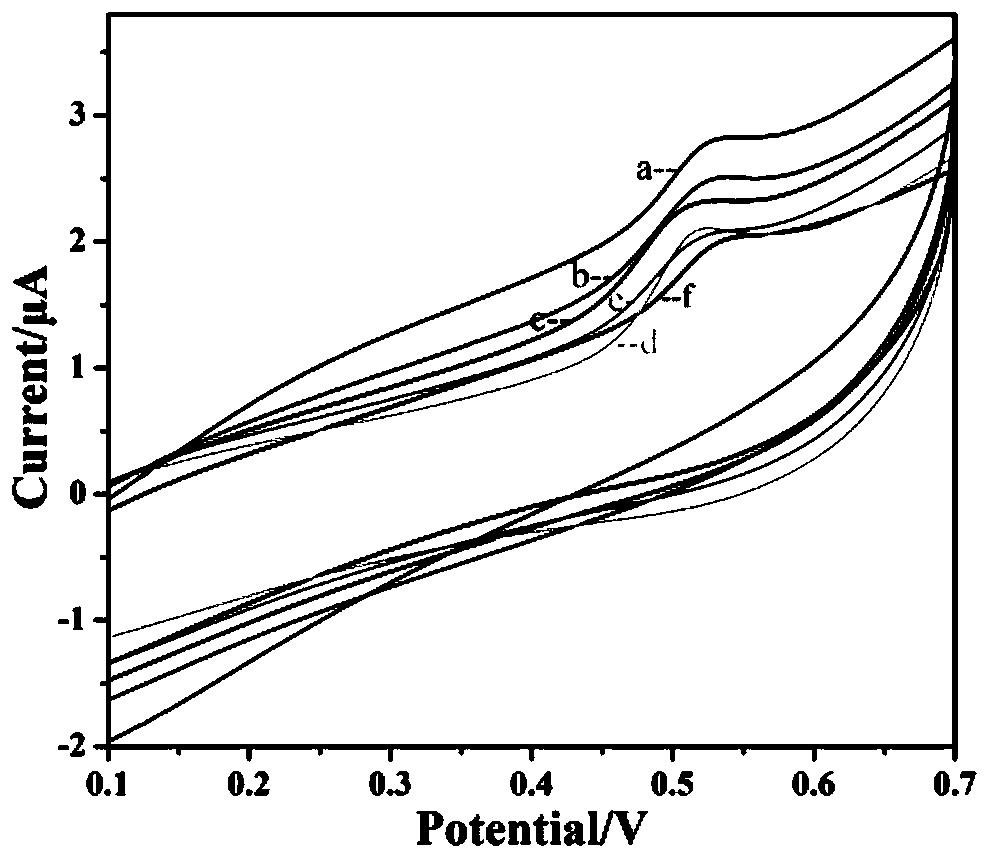

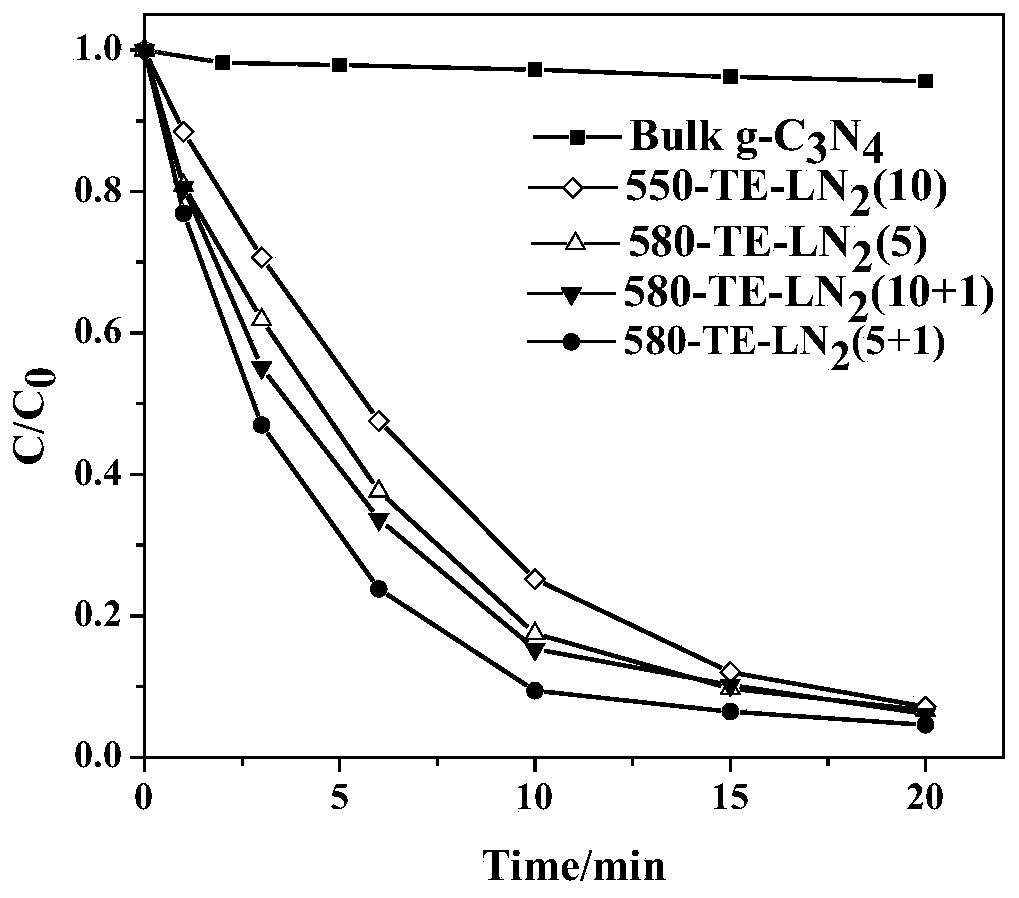

The invention relates to a preparation method of a carbon nitride ultrathin sheet with an adjustable atom layer number. The preparation method comprises the following steps: weighing 3-9g of Bulk g-C3N4 to be quickly heated to 550-580 DEG C in a container for thermal expansion for 10-20min and taking the same out; immediately adding liquid nitrogen till a sample is immersed; and after LN2 is volatilized fully, repeating the steps for 5-10 times to obtain the ultrathin sheet. The carbon nitride ultrathin sheet is prepared by the following steps: weighing 0.12-1.2g of the g-C3N3 ultrathin sheet obtained in the step (1) in the container to be quickly heated to 550-580 DEG C; keeping the temperature for 10-20min; and naturally cooling the same to room temperature to obtain g-C3N4 with a single atom layer and multiple atom layers. The preparation method provided by the invention has the advantages that by replacing a commonly used organic solvent ultrasonic peeling method with a cheap and non-toxic peeling agent, the prepared g-C3N4 ultrathin sheet is fast in process, low in cost, environmental-friendly and suitable for industrial preparation on a large scale.

Owner:武汉莱瑞医疗科技有限公司

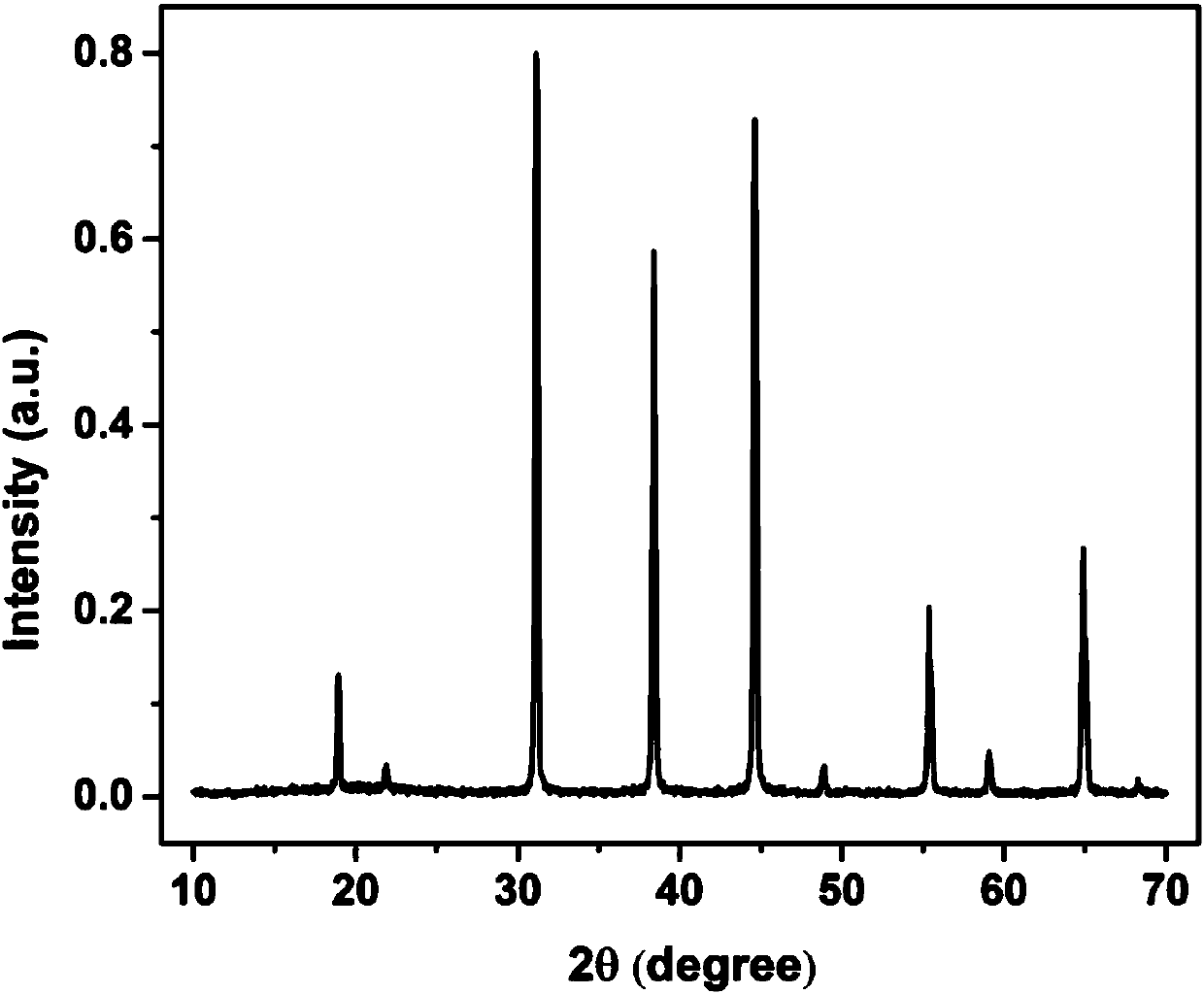

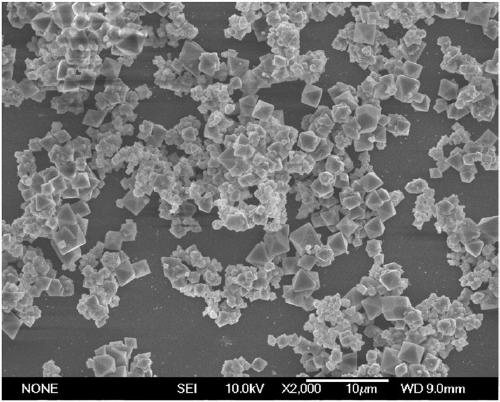

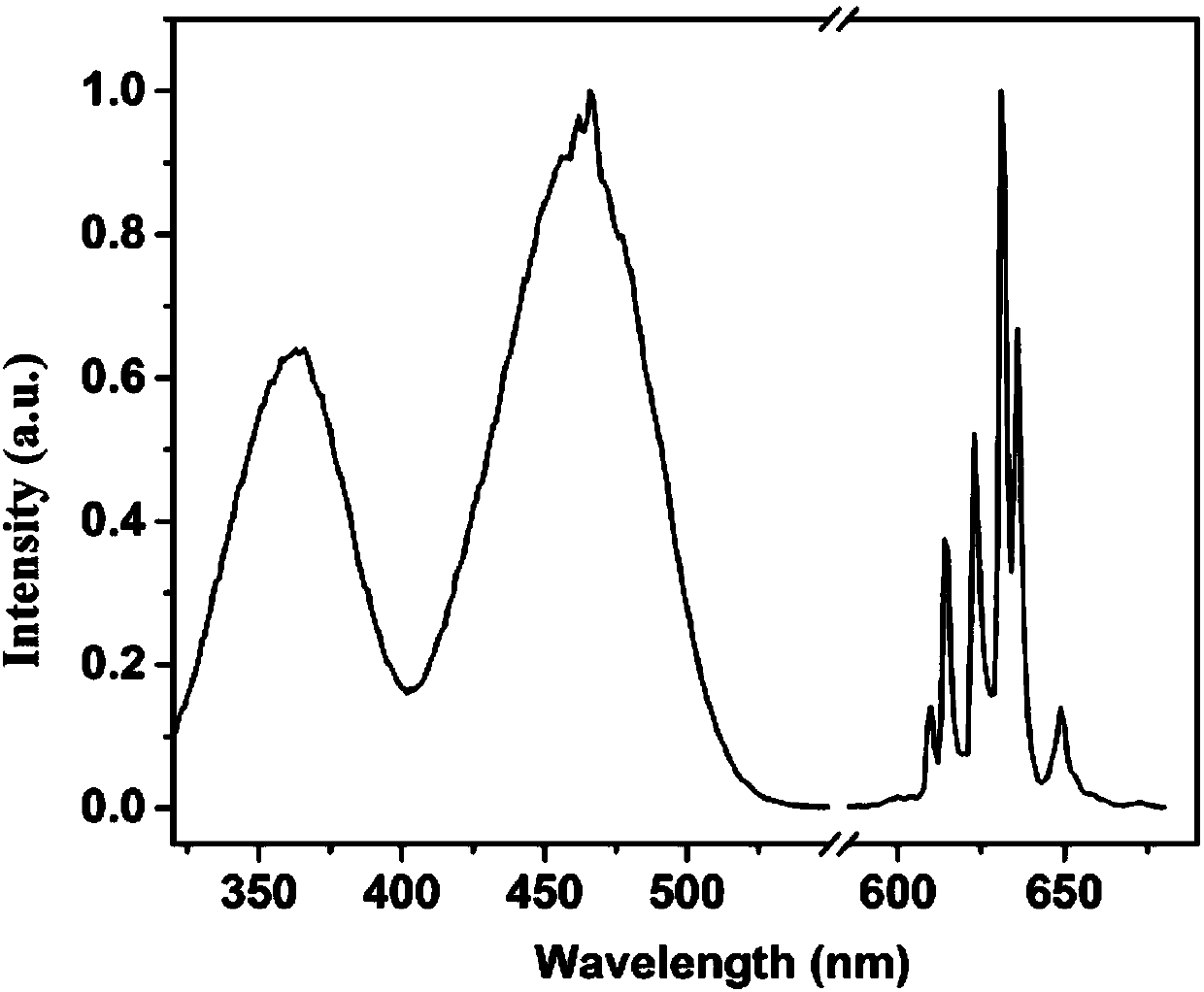

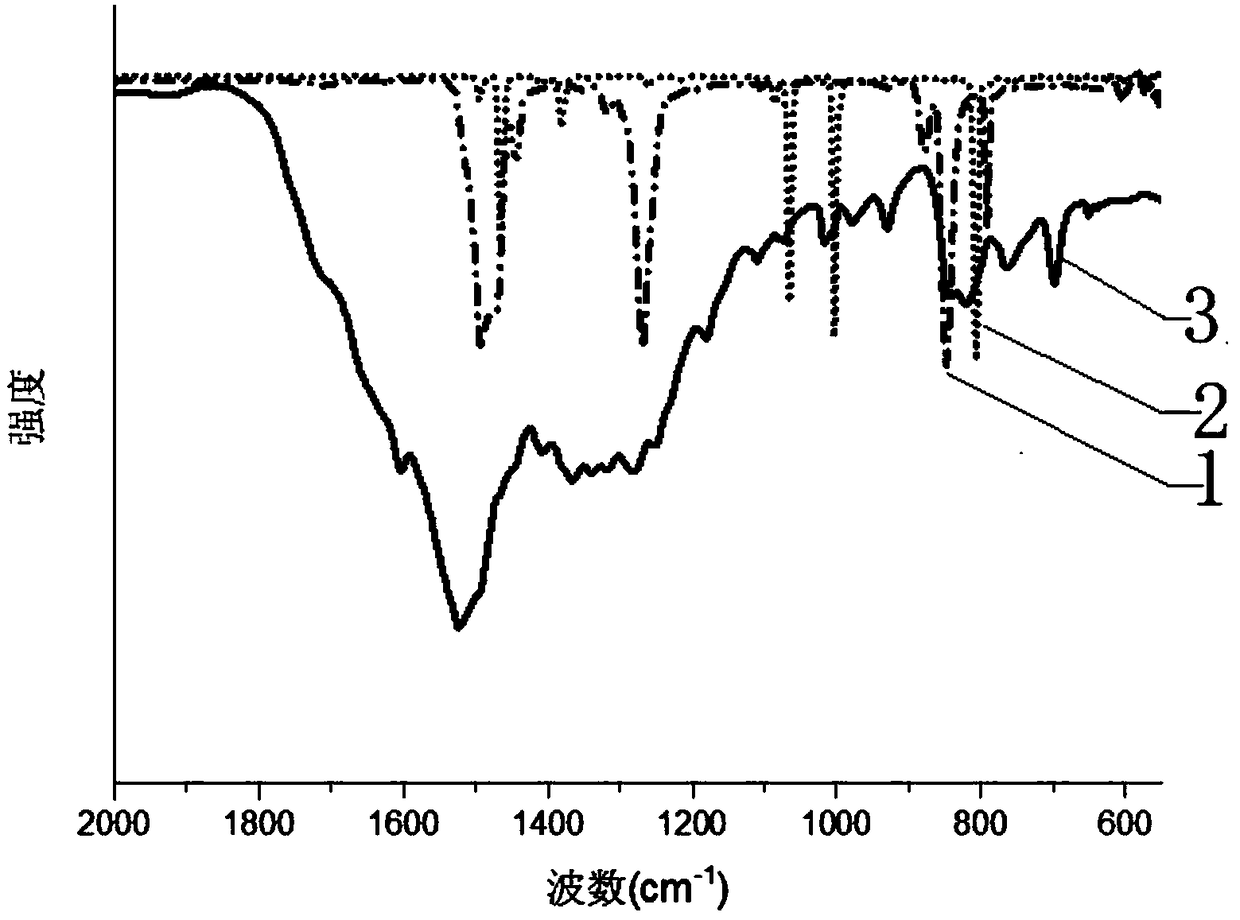

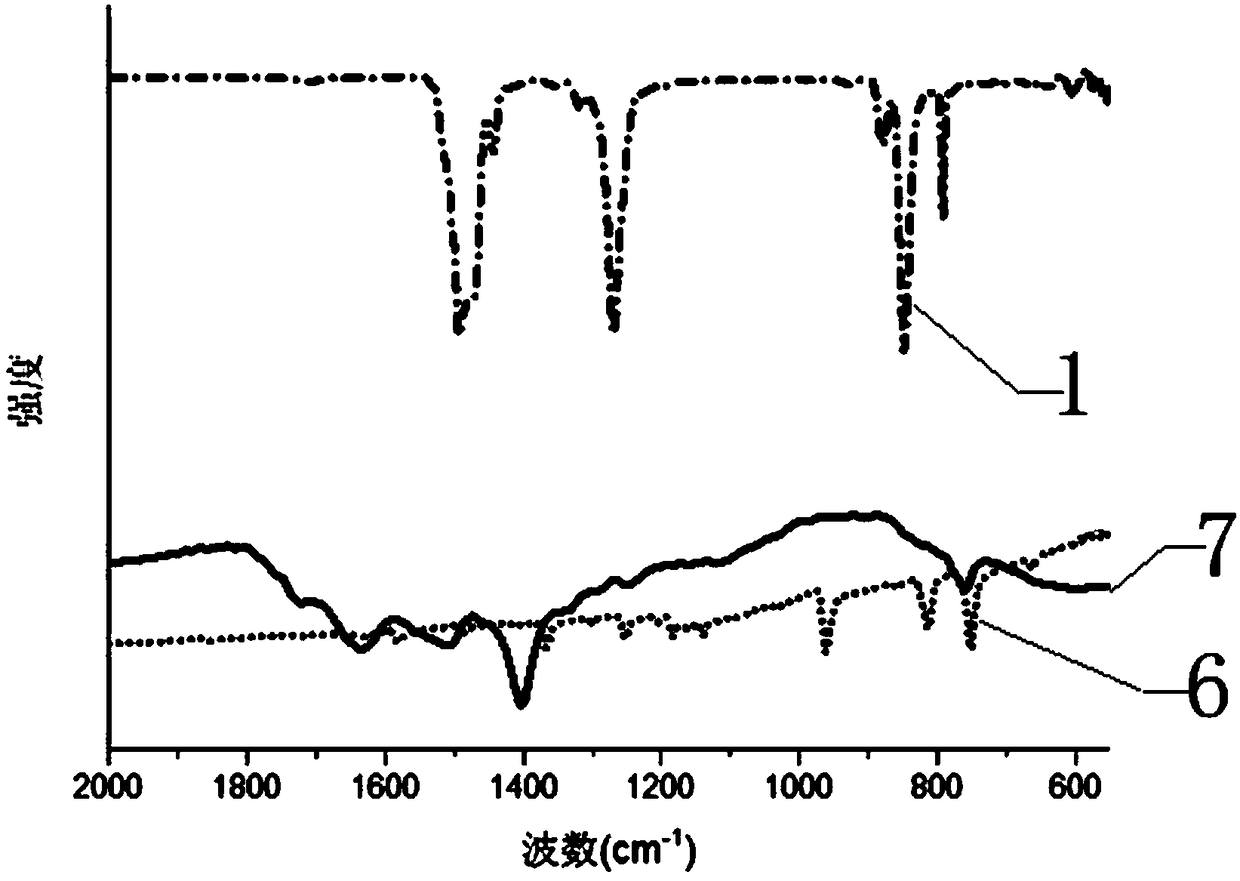

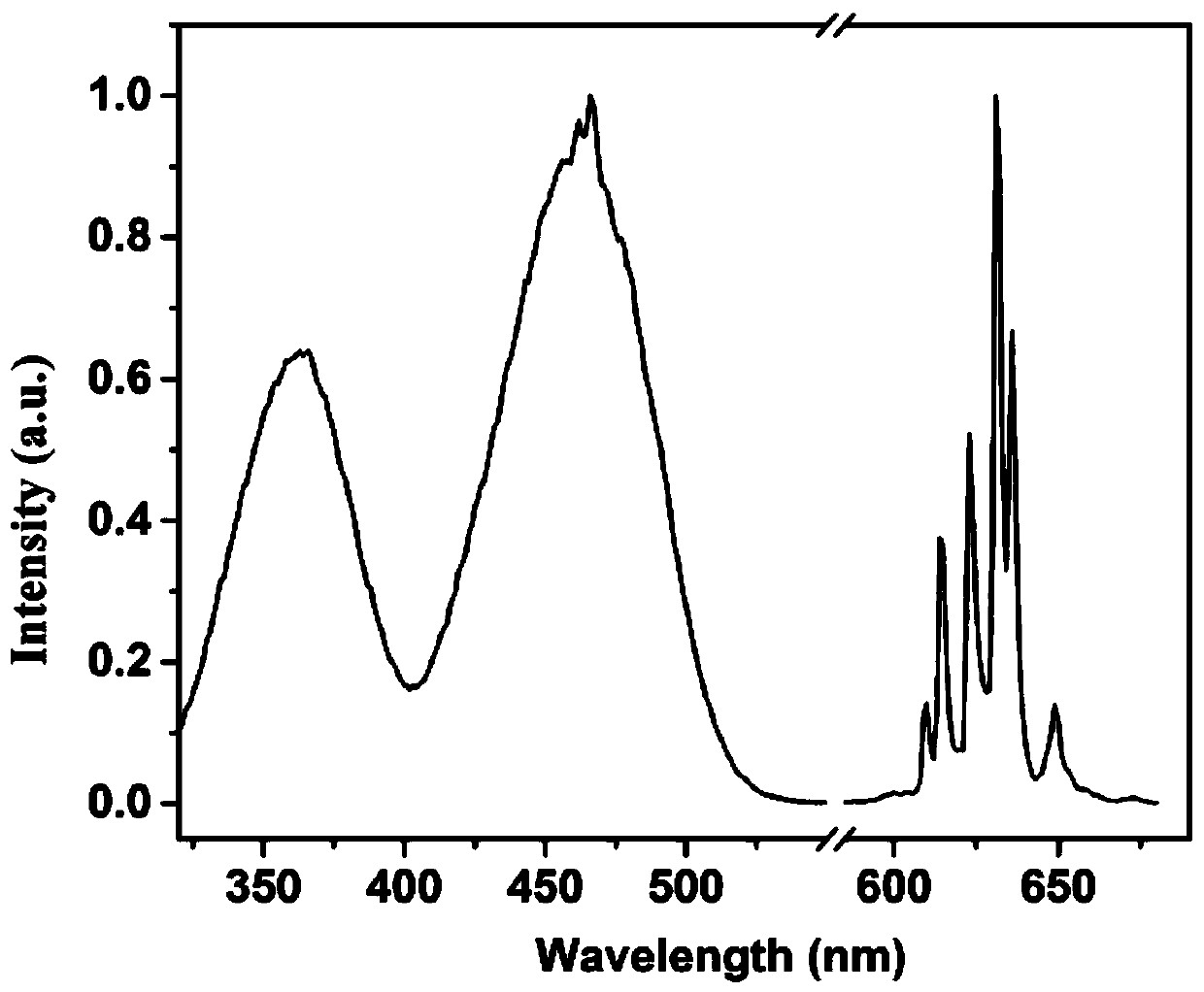

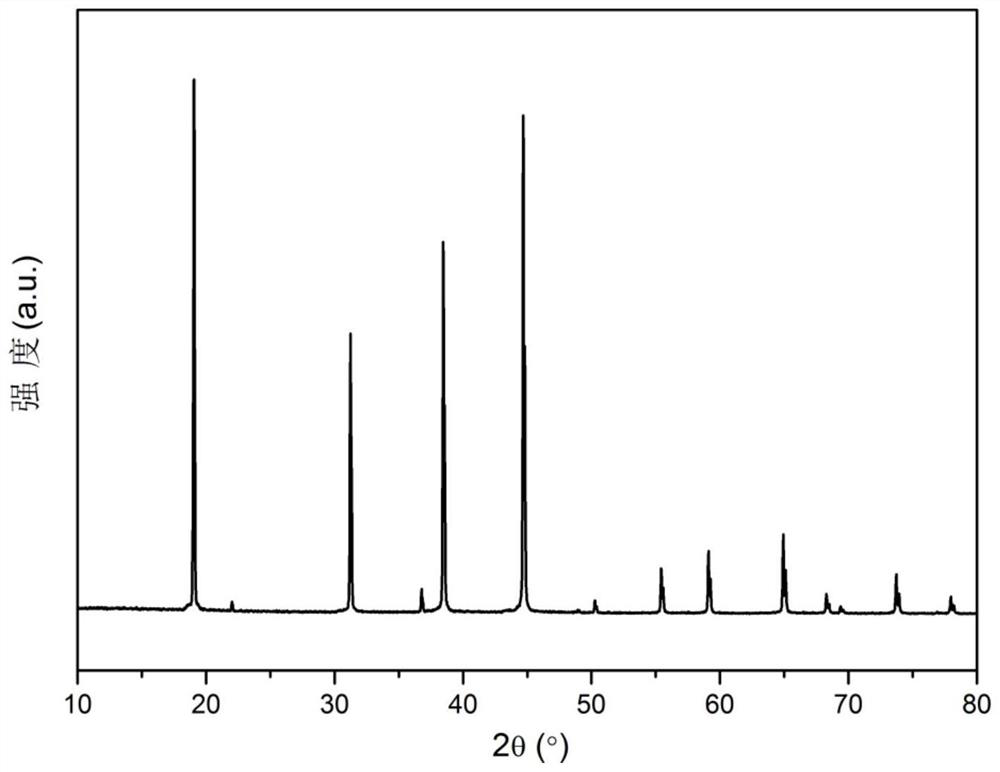

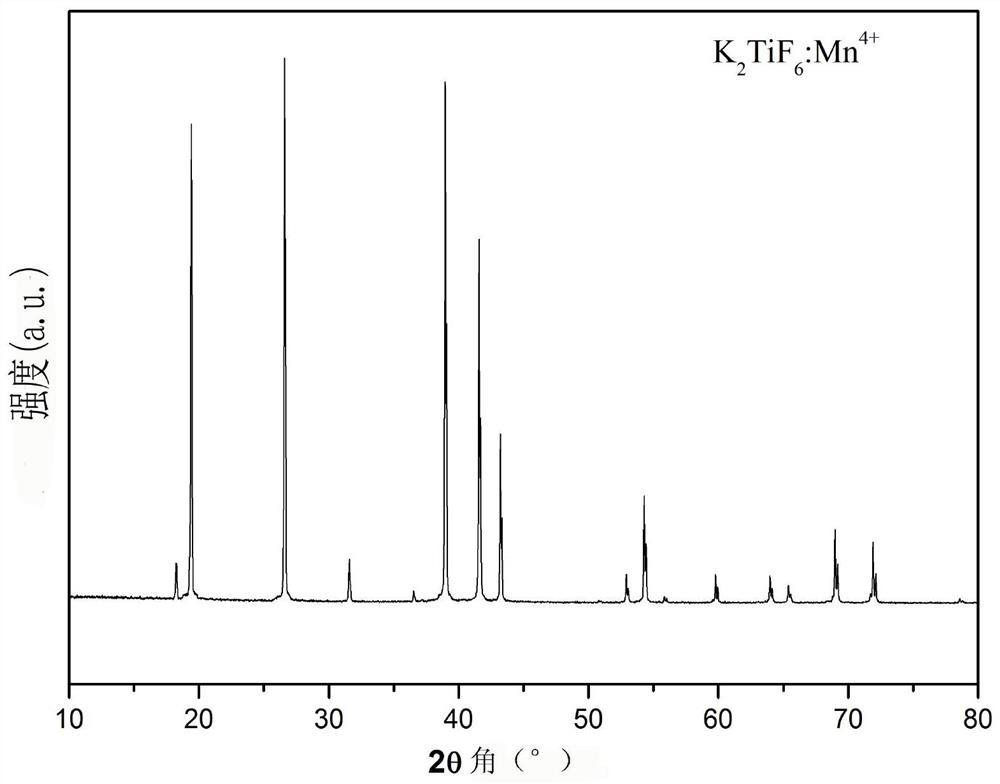

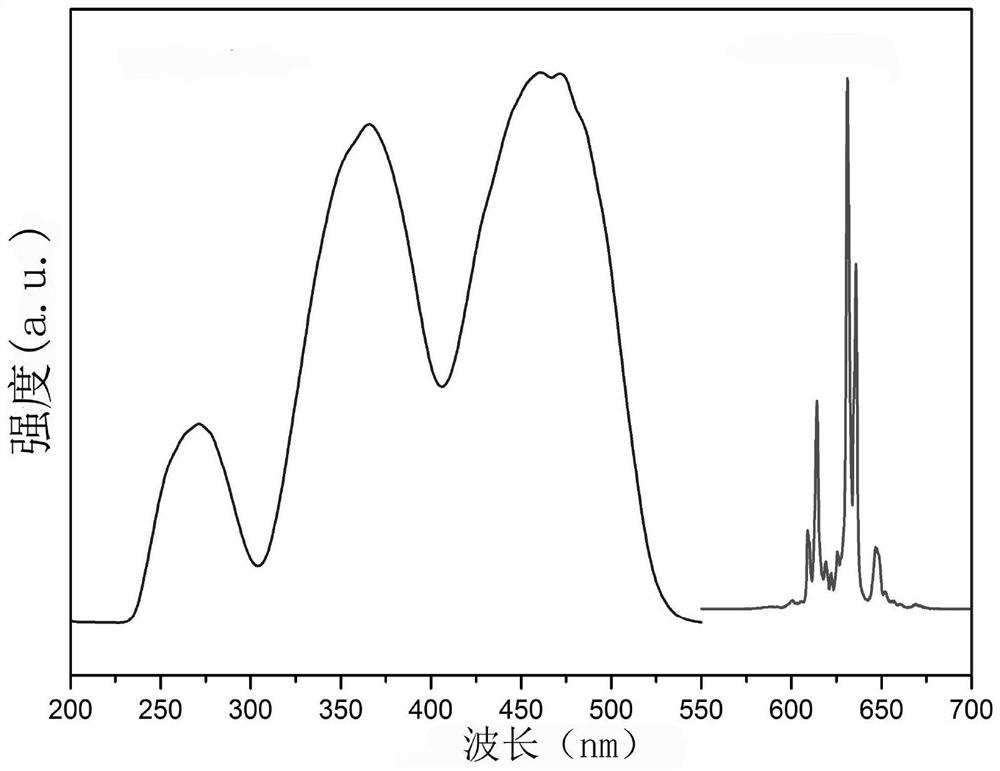

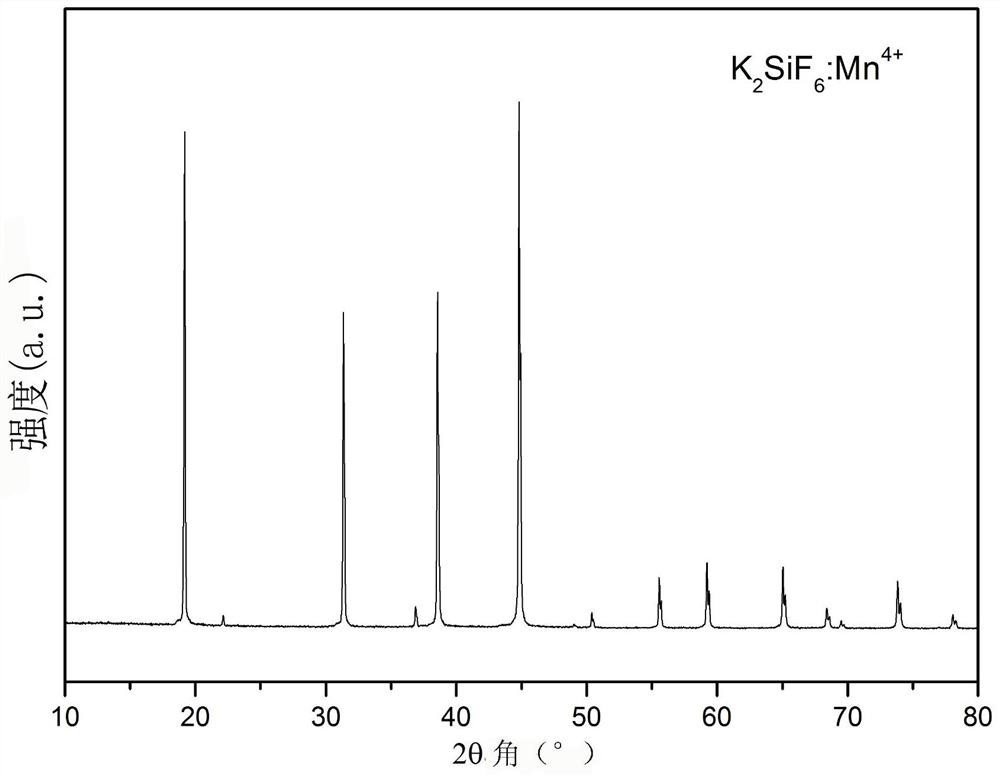

Preparation method of Mn<4+>-activated fluoride fluorescent powder

ActiveCN109957400AReduced dosage requirementsHigh Luminescence Quantum YieldLuminescent compositionsLuminescence quantum yieldOptical property

The invention provides a preparation method of Mn<4+>-activated fluoride fluorescent powder. The preparation method provided by the invention does not need to form a saturated solution of A2MF6, so that the requirement of the use amount of raw materials is greatly reduced; in the preparation process, the target product can be synthesized at room temperature and is convenient to synthesize; a precipitating agent is added, so that the preparation is more convenient, the operation is simpler, the synthetic steps are simplified, and the prepared fluorescent powder has better optical properties; the fluoride fluorescent powder can be well excited by ultraviolet light to blue light, especially the blue light, and has strong red light emission, wherein the red light emission peak is in the wavelength range from 600 to 650 nm; the method has the advantages of a simple preparation process and short consumed time; and the prepared material has a high luminescence quantum yield and is suitable for industrial large-scale preparation.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Method for preparing novel pressure-resistant building material

InactiveCN107417232AMeet the requirements of sustainable developmentImprove flexural strengthSlagDolomite

The invention discloses a method for preparing a novel pressure-resistant building material. The method comprises the following steps: I, mixing and uniformly stirring coal ash, a polymer, a coagulating material and water so as to obtain a mixture I; II, drying straw at 80-100 DEG C till the moisture is less than 5%, grinding in a grinding machine, and screening till the particle size is 200-300 meshes so as to obtain straw powder; III, performing ball-milling on magnesium calcium carbonate, blast furnace slag, clay, dolomite dust, feldspar powder and calcium borate in a ball-milling machine so as to obtain a mixture II, wherein the ratio of a milling media to materials is (12:1)-(20:1) in the ball-milling machine; and the ball-milling time is 50-60 minutes; IV, sequentially putting the straw powder and the mixture II into the mixture I, further adding hydroxypropyl methyl cellulose and butyl rubber, and heating and stirring at 300-380 DEG C for 40-45 minutes so as to obtain a base material; and V, introducing the base material into a mold, and performing pressurizing molding, thereby obtaining a finished product. The building material prepared by using the method has the characteristics of being high in breaking strength and high in pressure resistance.

Owner:合肥易美特建材有限公司

Filler for a supergravity rotation bed, preparation method and uses thereof

InactiveCN108686615AAvoid corrosionImprove mass transfer efficiencyChemical/physical/physico-chemical processesMaterials scienceNanotechnology

The invention discloses a filler for a supergravity rotation bed, wherein the filler comprises a substrate filler and a composite coating on the surface of the substrate filler, and the composite coating comprises a primer combined with the substrate filler and a low surface energy substance on the primer. According to the present invention, the filler has a good surface wetting effect, and can easily disperse the liquid phase and improve the mass transfer efficiency of the liquid phase. The invention further discloses a preparation method and uses of the filler.

Owner:BEIJING UNIV OF CHEM TECH

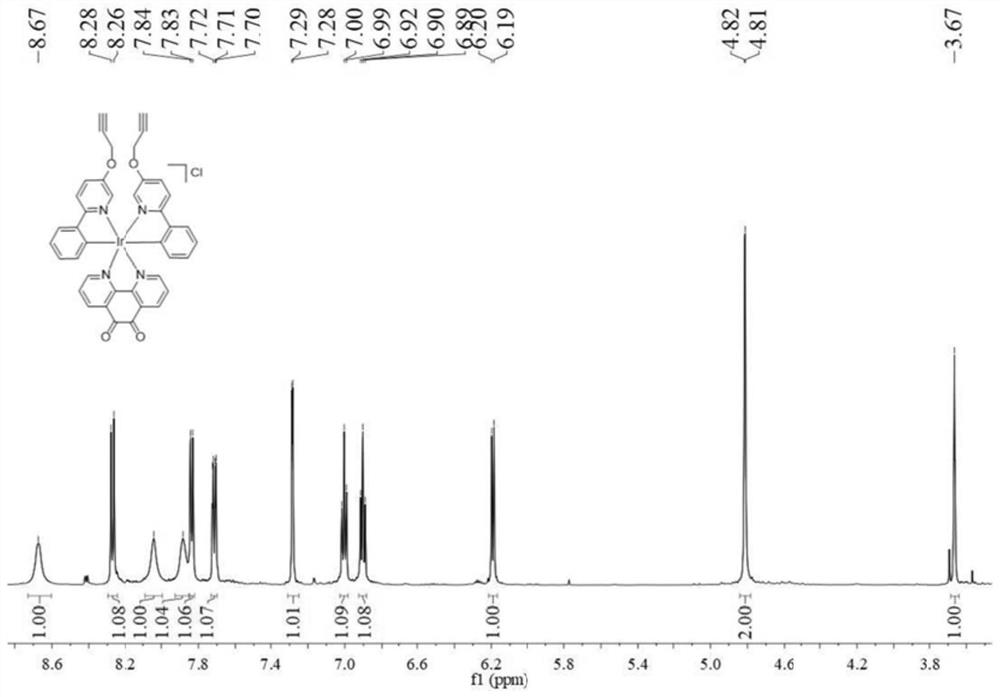

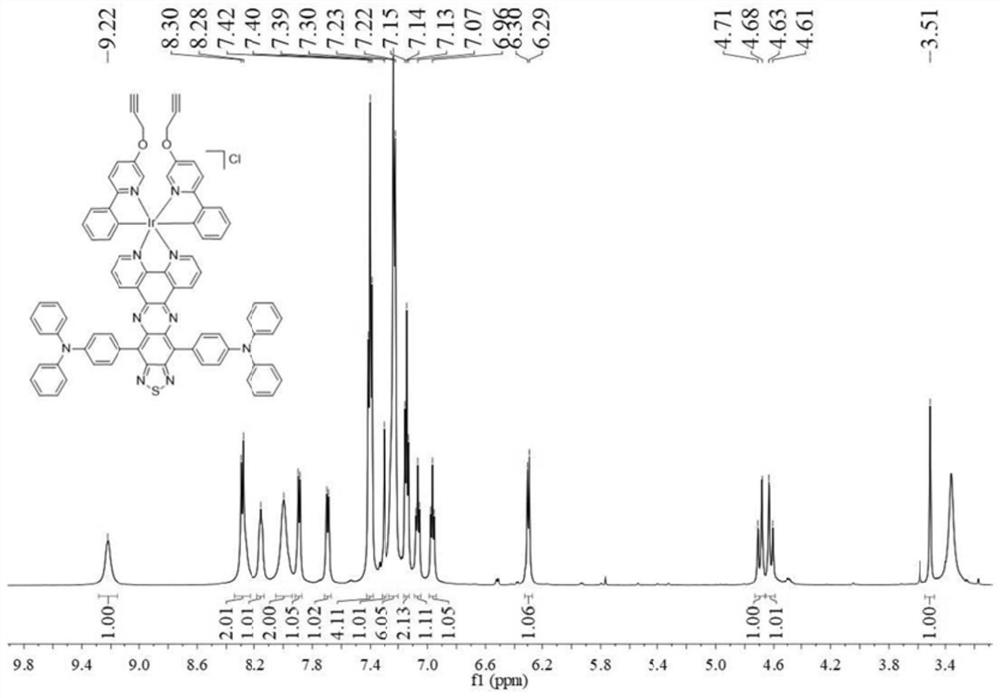

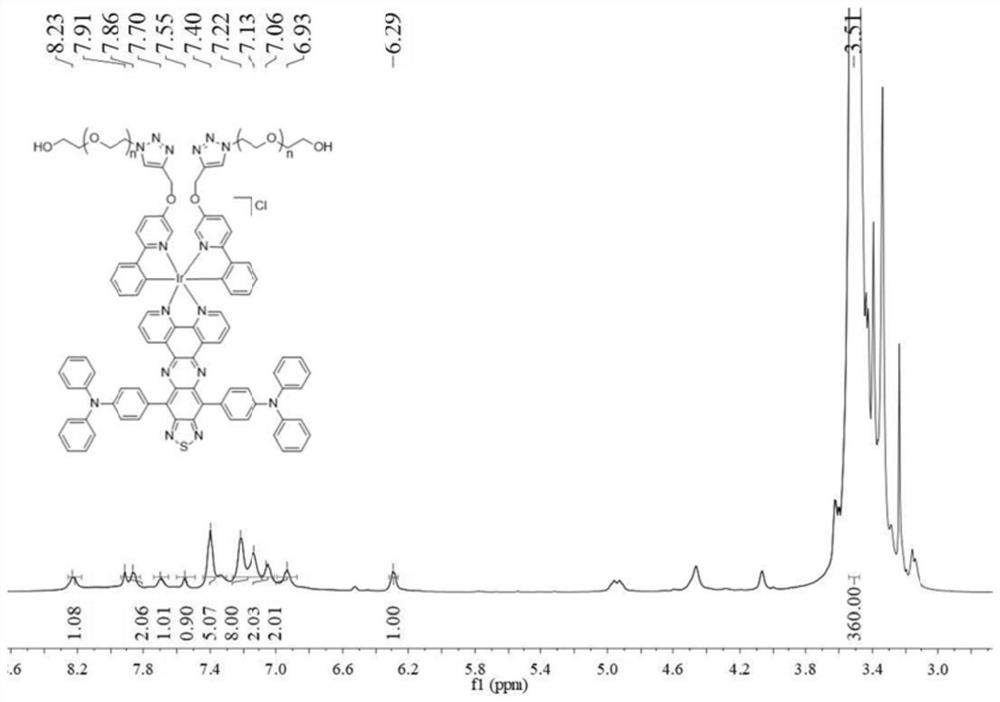

Metal polymer, metal polymer nano-micelle as well as preparation method and application of metal polymer nano-micelle

ActiveCN111939124AEasy to manufactureQuality is easy to controlPhotodynamic therapyPharmaceutical non-active ingredientsPolymer sciencePolyethylene glycol

The invention discloses a metal polymer, a metal polymer nano-micelle as well as a preparation method and application of the metal polymer nano-micelle. The metal polymer or pharmaceutically acceptable salt or solvate of the metal polymer is shown as a formula I or a formula II; alkynyl is introduced into metal iridium and ruthenium complexes and reacts with water-soluble monoazide polyethylene glycol through a click reaction to synthesize the metal polymer, and the metal polymer can be self-assembled into a nano-micelle with a core-shell structure in an aqueous solution. The preparation method is simple and convenient, the reproducibility is good, the quality is controllable, in addition, the nano-micelle can greatly improve the biocompatibility of metal drugs, can be applied to optical treatment, and has potential anti-tumor application prospects.

Owner:SOUTHEAST UNIV

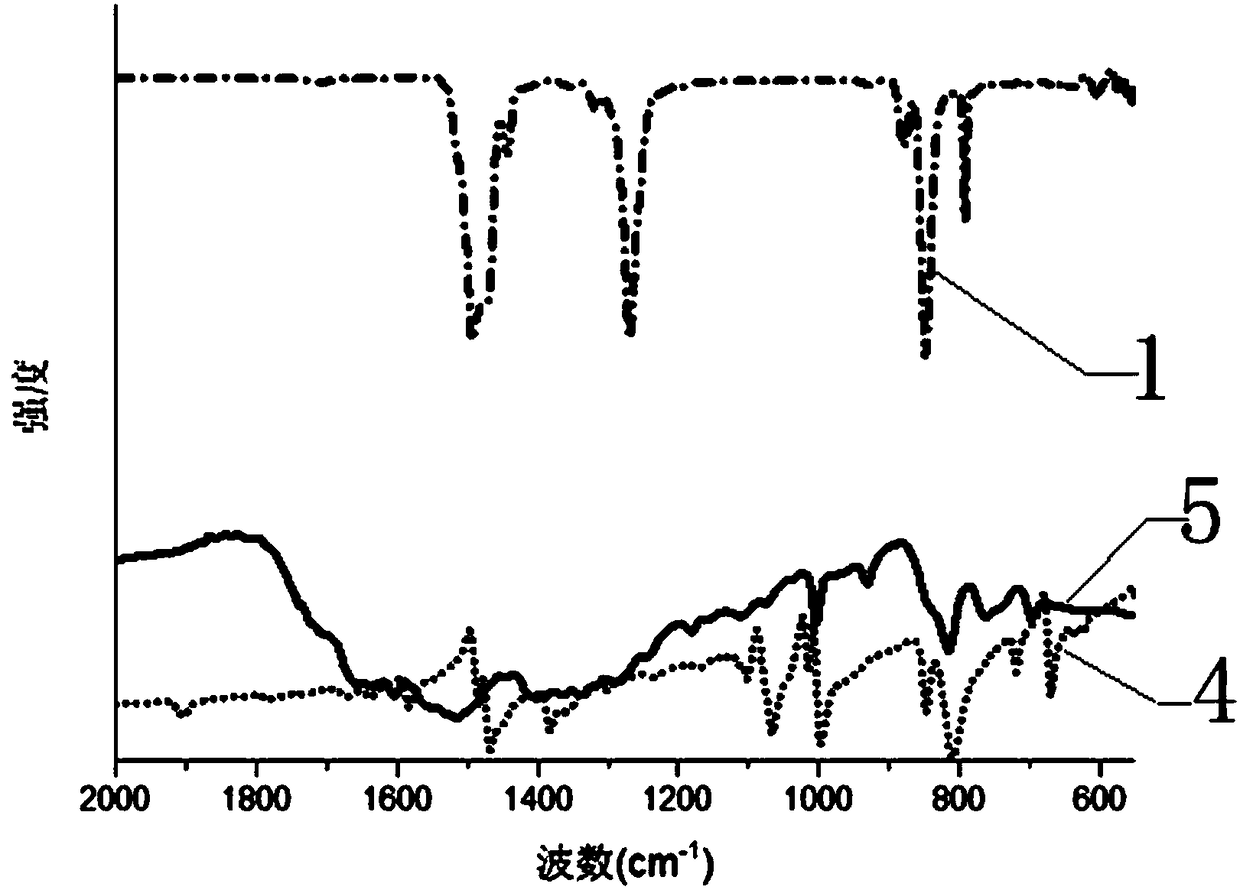

Surface modification method of fluoride luminescent material, and fluoride luminescent material prepared by method

ActiveCN111171815AImprove corrosion resistanceReduce surface defectsEnergy efficient lightingLuminescent compositionsQuantum yieldQuantum efficiency

The invention relates to a surface modification method of a fluoride luminescent material, and the fluoride luminescent material prepared by the method. According to the invention, a matrix material AxMFy:Mn<4+> coated with an inorganic coating layer AxMFy, and an organic solution containing metal phosphate or alkoxy silane or an organic carboxylic acid substance or organic amine, and the obtainedmixed solution is subjected to evaporation drying to obtain the surface-modified fluoride luminescent material co-coated with the organic coating layer-inorganic coating layer; according to the coating method, the corrosion resistance of the fluoride fluorescent powder is remarkably improved, the luminous intensity retention rate and the quantum efficiency retention rate of the modified fluorescent powder reaches 85-95% in a high-temperature and high-humidity environment, and the fluoride fluorescent powder can be widely applied to the field of white light LED backlight source display; afterinorganic coating, the surface defects of the fluorescent powder are reduced, and the luminous intensity and the quantum yield of the fluorescent powder are improved by 5%-15%; after coating with theorganic coating layer, the luminous intensity reducing of the fluorescent powder is less than 3%; and the surface modification method provided by the invention has the advantages that the preparationtemperature is low, the time is short, the process is easy to control, and the surface modification method is suitable for industrial large-scale preparation.

Owner:XIAMEN INST OF RARE EARTH MATERIALS

Process for preparing lithium iron phosphate by using liquid phase cocrystallization and mechanical alloying

The invention provides a process for preparing lithium iron phosphate by using liquid phase cocrystallization and mechanical alloying. The method is characterized by comprising the following steps: 1) wet ball-milling: mixing various raw materials in a wet ball mill and performing wet ball-milling on the mixture for 3-5 hours, wherein the particle size of the ball-milled raw materials is controlled at 100 meshes, the molar ratio of Fe to Li to PO4<3-> to dispersing agent to doping elements in the raw materials is 1:1:1:0.01-0.015:0.005-0.007, wherein the iron source is selected form ferric oxalate, ferric oxide and ferrous phosphate, the lithium source is selected form LiH2PO4 and Li2CO3, the phosphorus source is selected form NH4H2PO4 and LiH2PO4, the dispersing agent is cetyl trimethyl ammonium bromide, and the doping elements are an arbitrary mixture of yttrium oxide, titanium oxide and chromium oxide; 2) drying: drying the ball-milled raw materials; 3) presintering: performing presintering on the dried raw materials at a temperature of 300-400 DEG C for 4-6 hours; 4) dry ball-milling: adding 1-2wt% of starch into the above-mentioned raw materials, and performing dry ball-milling on the mixture to obtain a material with a particle size of 300 meshes; 5) high-temperature sintering: performing sintering on the mixture at a temperature of 650-700 DEG C for 8 hours; 6)smashing the mixture to obtain a final product of lithium iron phosphate. The process provided in the invention is applicable to industrial large-scale preparation. The products prepared according to the process have an uniform particle size and good electrical conductivity performance.

Owner:淄博赛动能源材料有限公司

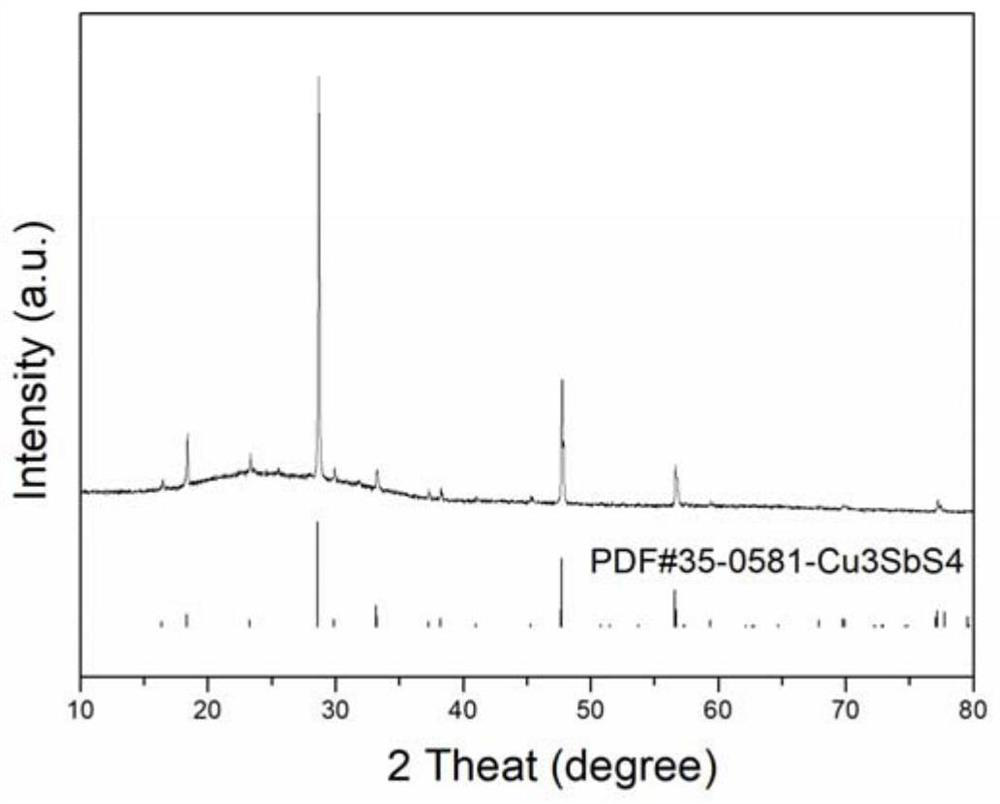

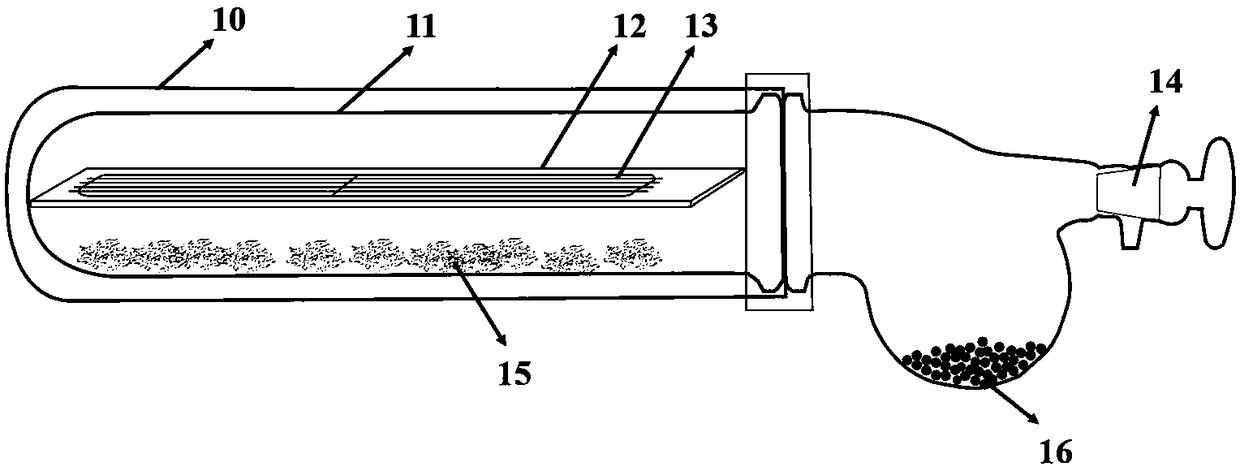

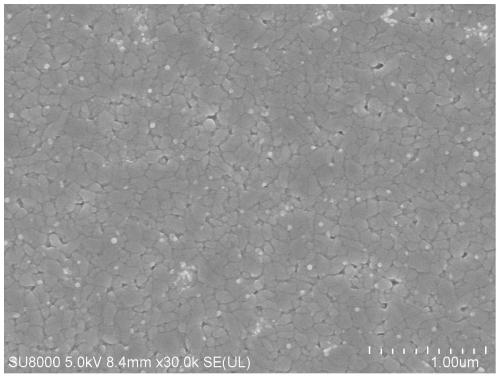

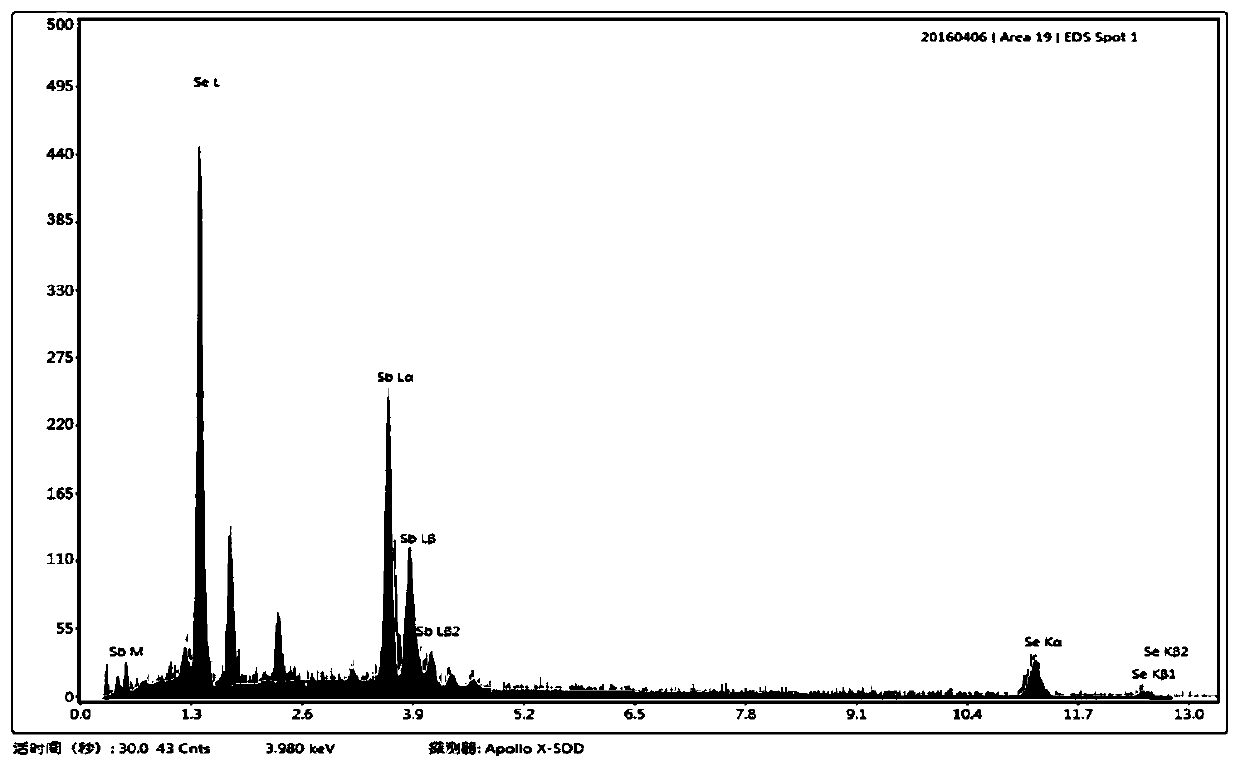

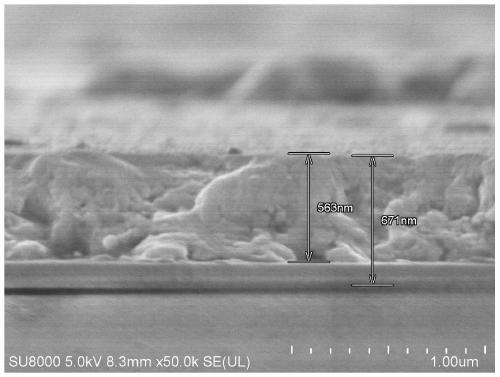

Method for preparing antimony tetrasulfide tricopper film of solar cell absorption layer through gas-solid reaction

PendingCN112481593AEasy to operateStable sputtering environmentFinal product manufactureVacuum evaporation coatingThin membraneMetal foil

The invention discloses a method for preparing an antimony tetrasulfide tricopper film of a solar cell absorption layer through a gas-solid reaction. A substrate is one of a molybdenum-plated film, conductive glass, soda-lime glass, quartz glass or metal foil; the purity of a Cu target material subjected to magnetron sputtering is 99.8%; the Cu target material is deposited on the clean substrate in an argon atmosphere through magnetron sputtering to form a Cu precursor film; and the obtained Cu precursor film is placed in a Sb2S3+S atmosphere for heat treatment to finally obtain the Cu3SbS4 film. According to the method, the gas-solid reaction is carried out after magnetron sputtering of the Cu precursor film, and the method has the advantages that the synthesized film is pure and single in phase formation, simple in manufacturing process, safe, non-toxic, not complex in preparation equipment, capable of achieving large-area production, easy to control in thickness and the like.

Owner:FUJIAN NORMAL UNIV

Large-scale preparation method for covalence copolymer with triazine frame

ActiveCN108395544ASimple reaction conditionsReduce manufacturing costReaction temperatureRoom temperature

The invention discloses a large-scale preparation method for a covalence copolymer with a triazine frame. The method comprises the steps of 1, preparing a nucleophilic reagent; 2, performing a polymerization reaction, wherein the prepared nucleophilic reagent and a triazine compound are mixed in a reaction solvent under the protective atmosphere, a reaction is performed under the temperature of 80-120 DEG C, and cooling is performed to reach the room temperature to obtain a reaction mixture; 3, performing postprocessing, wherein a quenching agent is added into the reaction mixture, and filtering, cleaning and drying are performed to obtain the covalent triazine polymer. A wet method is adopted for preparing the covalent triazine polymer, reaction conditions are simple, the production costis low, and the good industrial application prospect is achieved. The preparation method has no special requirement for operation equipment, the reaction temperature is not high, and therefore industrialized enlarged production is easily performed.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

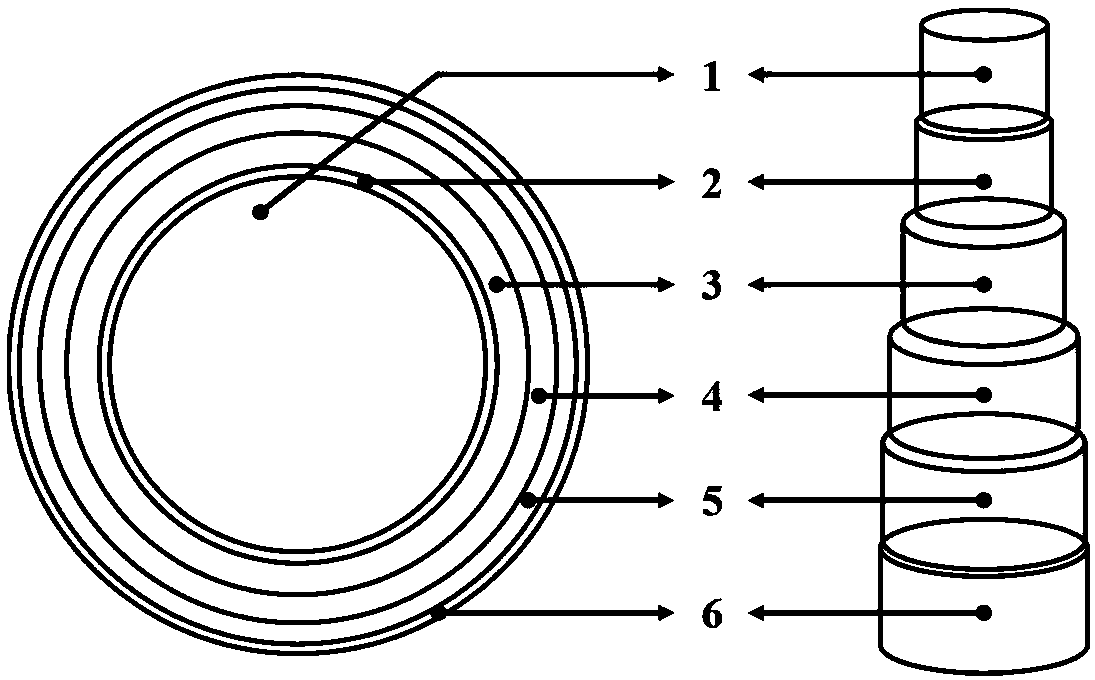

Fibrous perovskite solar cell and preparation method and application thereof

InactiveCN108878655AImprove adhesionGood film formingSolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellPorous layer

The invention relates to a fibrous perovskite solar cell and a preparation method and application thereof. The solar cell takes a titanium wire serving as an electrode as the center and sequentially comprises the titanium wire serving as the electrode, a titanium dioxide compact layer, a titanium dioxide porous layer, a perovskite crystal layer, a hole transporting layer and thin gold serving as an opposite electrode from inner to outside in the radial direction of the solar cell. The prepared fibrous perovskite solar cell can greatly improve the energy conversion efficiency (which can reach up to 9%), can easily achieve big-size preparation and provides an effective guarantee for being applied to the fields of wearable equipment, smart home and the like.

Owner:BEIJING INST OF COLLABORATIVE INNOVATION

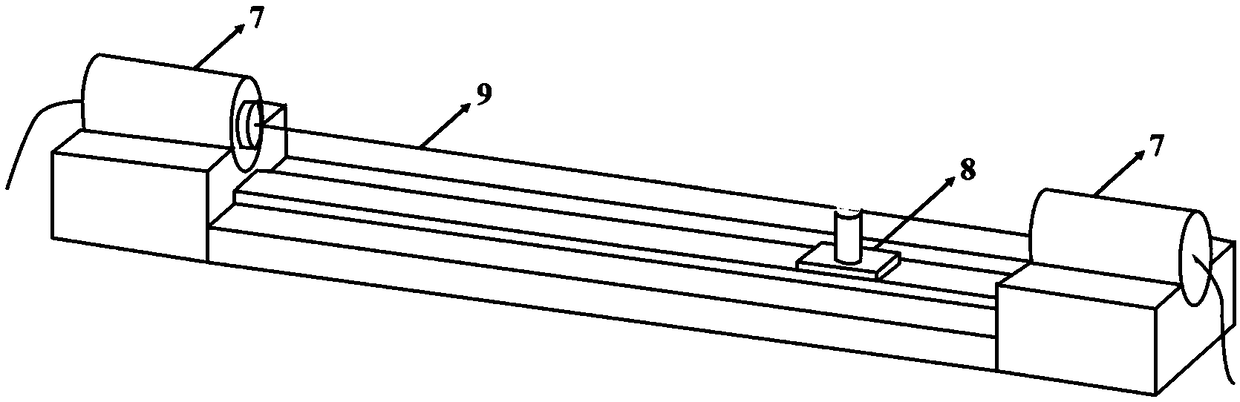

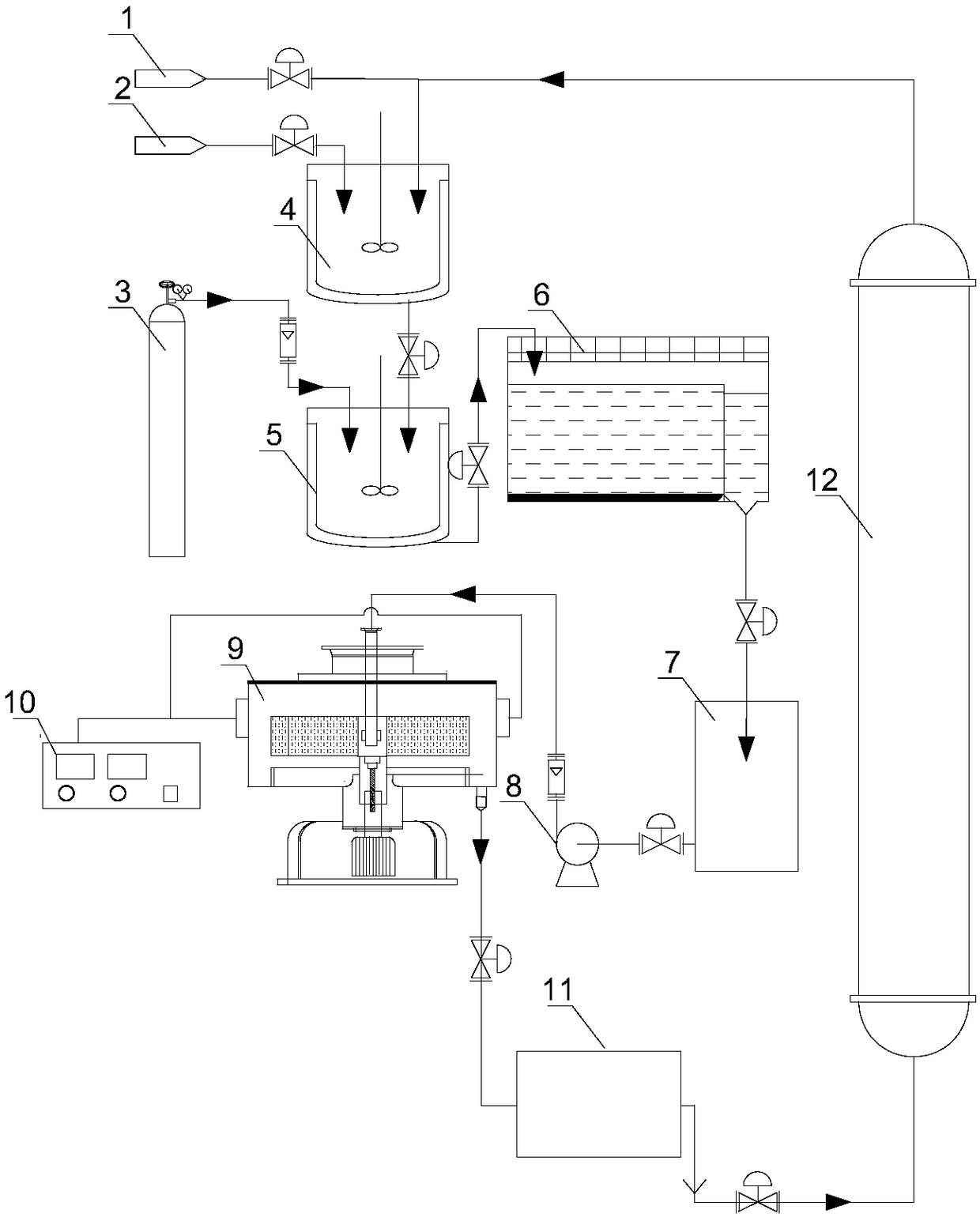

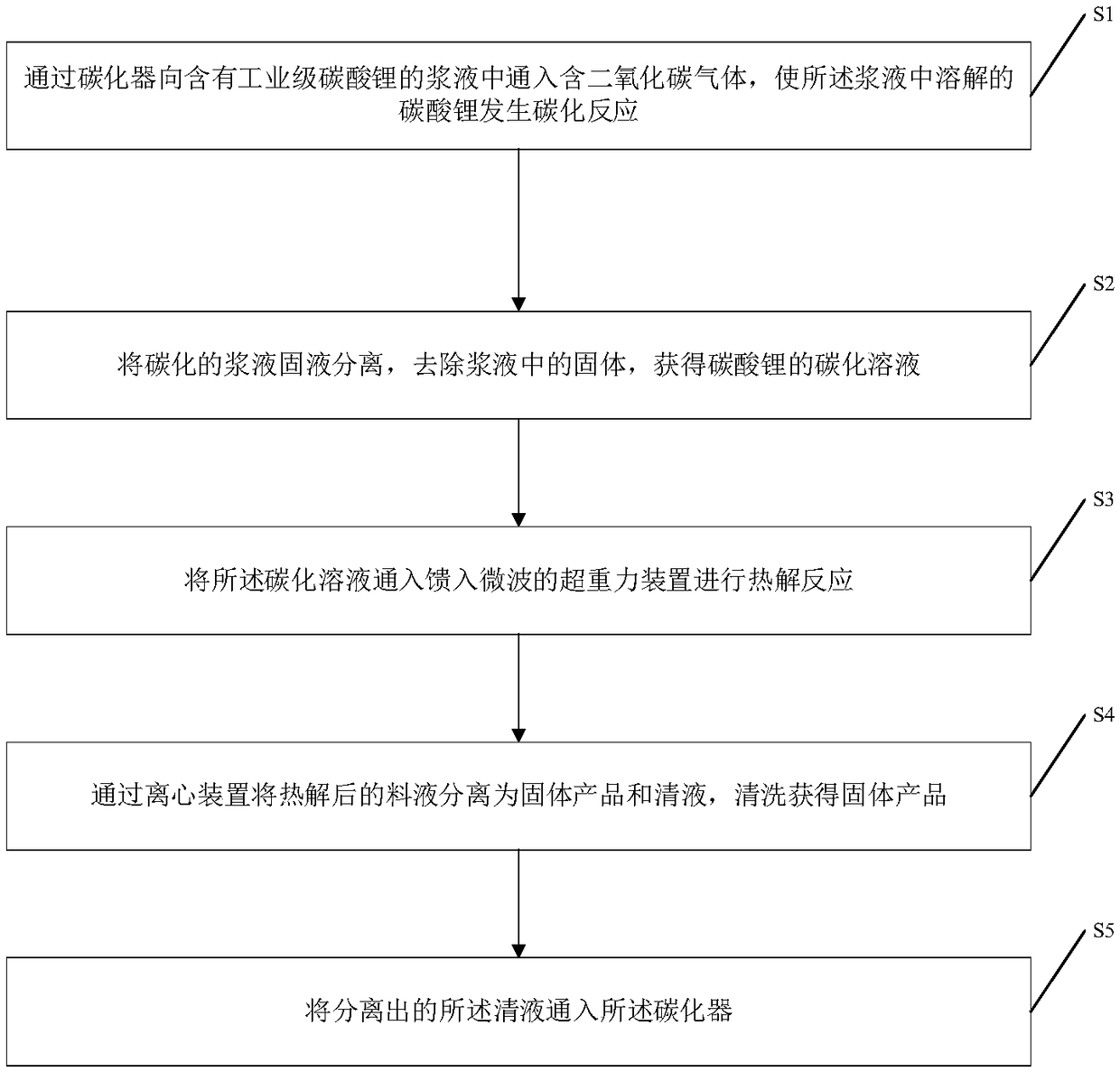

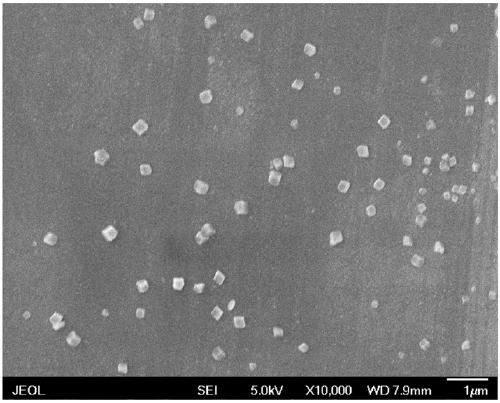

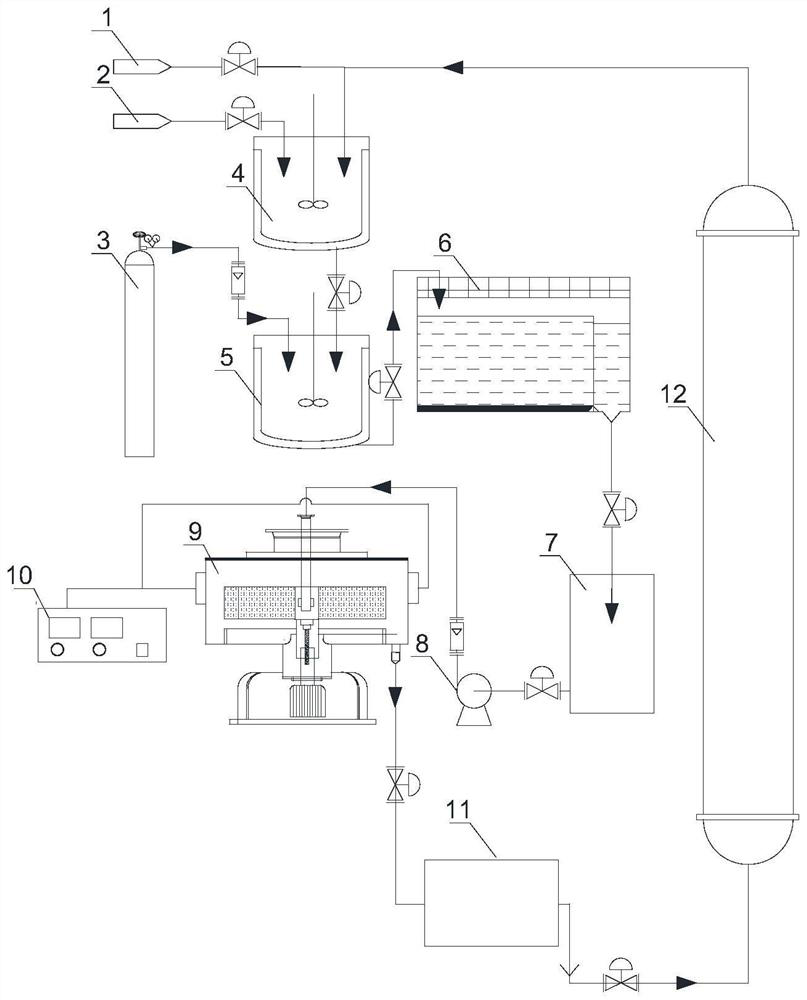

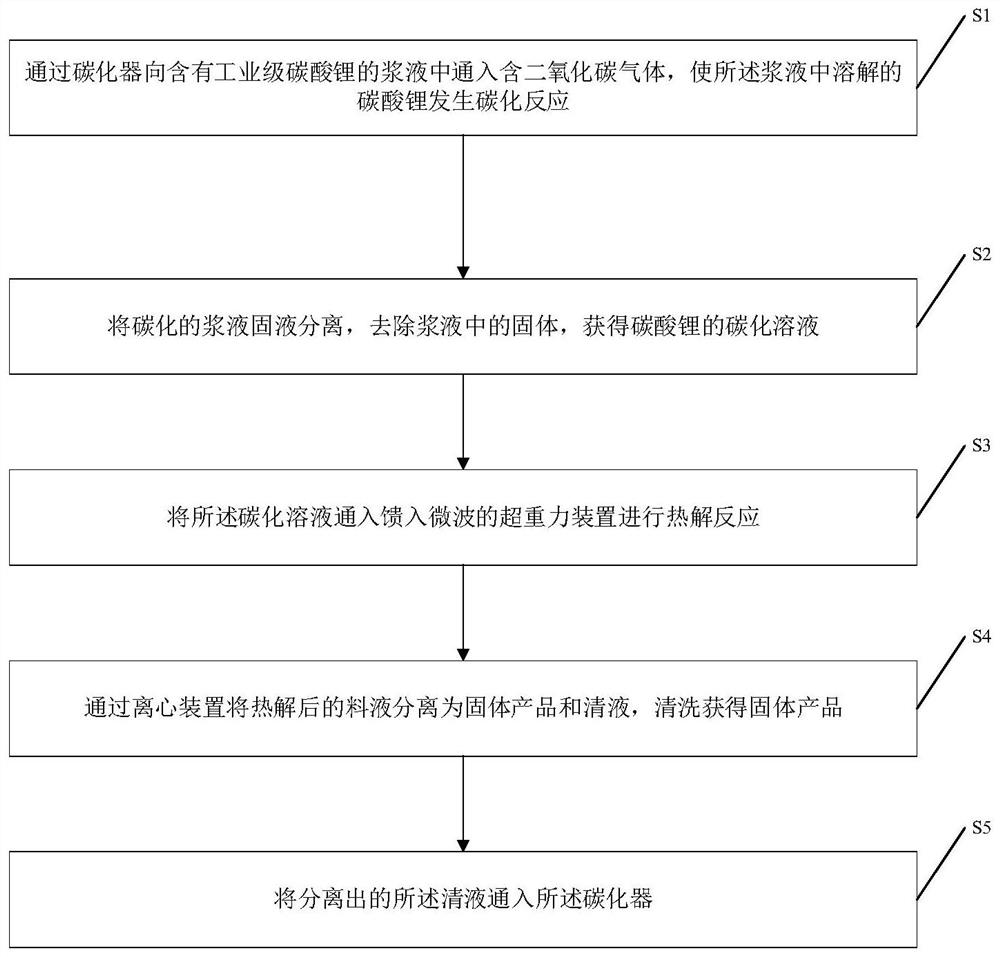

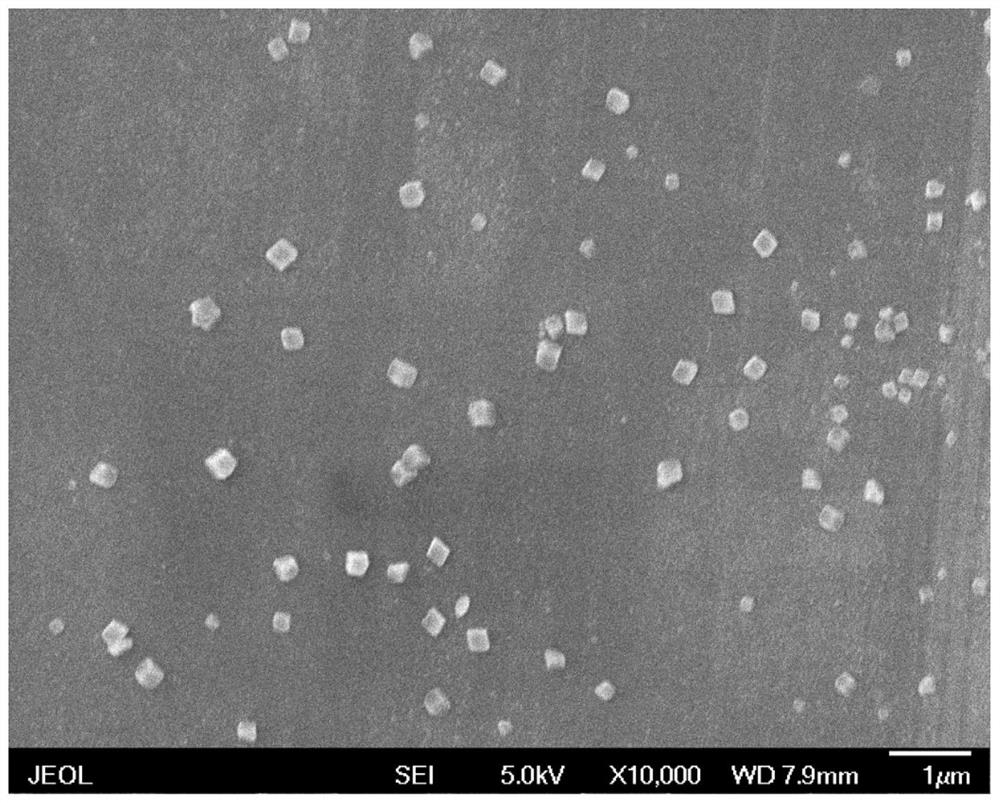

System and method for extracting industrial lithium carbonate by supergravity

ActiveCN108975357AReduce distributionSuitable for industrial large-scale preparationAlkali metal carbonatesMicrowaveLithium carbonate

The invention discloses a system and a method for extracting industrial lithium carbonate by supergravity. The system comprises a carbonizer, a solid and liquid separating device, a microwave-coupledsupergravity device, and a centrifuge device which are sequentially connected by pipelines. The system has the advantages that by combining the supergravity technique, the centrifuge device and a recycling device, the shape and particle size of the pyrolyzed lithium carbonate are averagely distributed, the distribution of small-particle and large-particle solid products is reduced, the size of centrifuge force of the centrifuge device can be adjusted according to the obtained particle size, and most of solid products with uniform particle size are thoroughly settled by the centrifuge force; asupernatant is recycled by the recycling device, so that a small amount of small particles suspended in the supernatant can be dissolved and pyrolyzed again, and be recycled; the battery-level or high-purity lithium carbonate solid product with yield rate reaching the industrial preparation standard can be obtained; the system is suitable for industrialized large-scale preparation.

Owner:BEIJING UNIV OF CHEM TECH

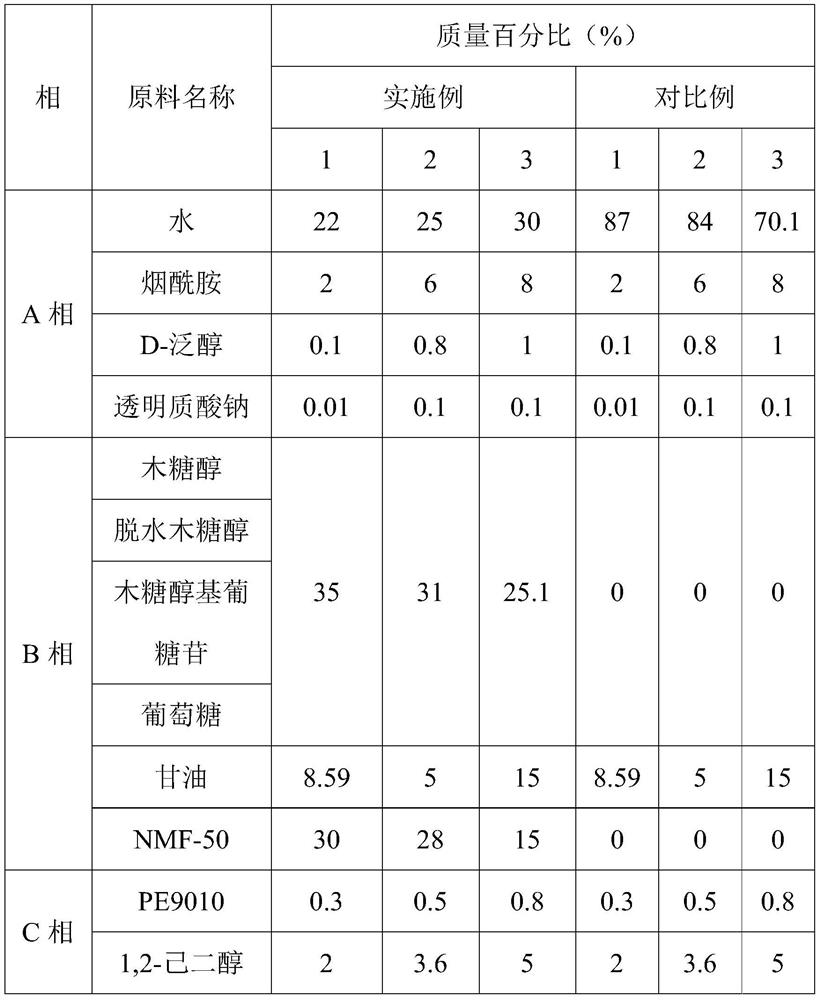

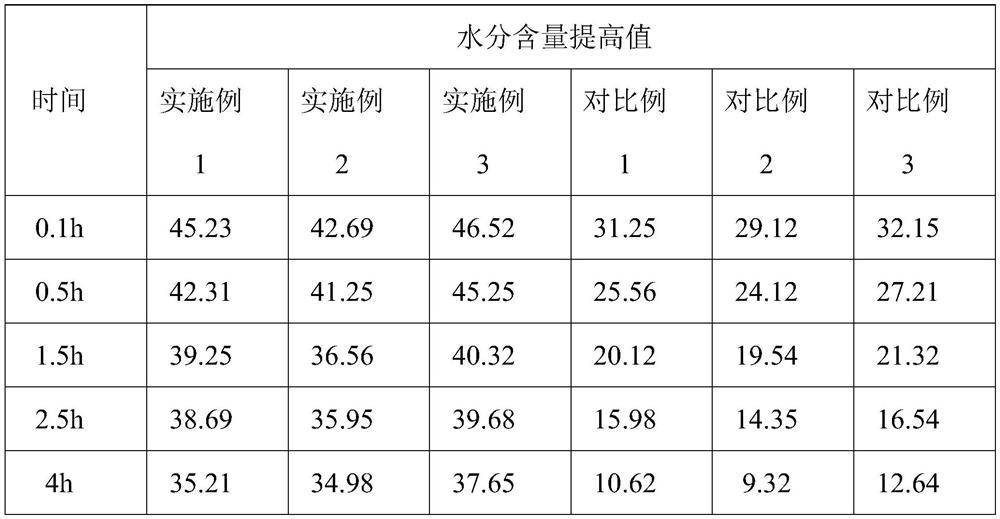

Composition for whitening and moisturizing skin and preparation method thereof

PendingCN114366689AImproves fine textureHas moisturizing effectCosmetic preparationsToilet preparationsGlycosideGlycerol

The invention discloses a composition for whitening and moisturizing skin and a preparation method thereof, and belongs to the technical field of cosmetics, the composition comprises the following raw materials in percentage by weight: phase A: 22-30% of water, 2-8% of nicotinamide and 0.01-0.1% of sodium hyaluronate; a phase B: 25 to 35 percent of AQUAXYL, 5 to 15 percent of glycerol and 15 to 30 percent of NMF-50; wherein the AQUAXYL is prepared from xylitol, dehydrated xylitol, xylitol-based glucoside and glucose; the sum of the raw materials of the phase A and the phase B is 100%, and the finally prepared composition has the effects of whitening and moisturizing the skin; the preparation method of the composition for whitening and moisturizing the skin, provided by the invention, has the advantages of simple steps and mild reaction conditions, is suitable for industrial large-scale preparation, and also can keep the activity.

Owner:广州市妆妍生物技术有限公司

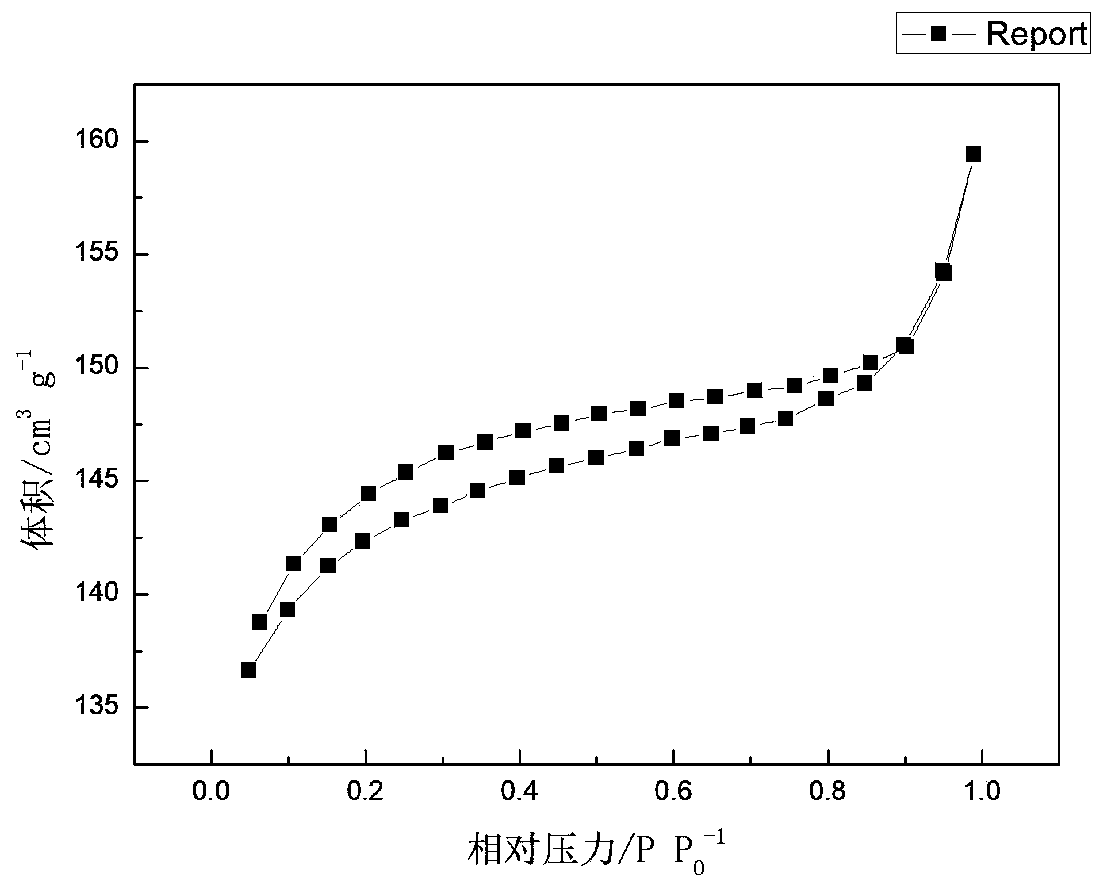

Preparation method of carbon nanocage material

ActiveCN110078051BSave raw materialsRaw materials are non-toxicNano-carbonCarbonizationPhysical chemistry

The present invention relates to the technical field of carbon nanomaterials, and specifically relates to a preparation method for a carbon nanocage material. The method comprises: a carbohydrate is used as a carbon source, and potassium chloride is used as a template, so that the raw materials are cheap, nontoxic, and pollution-free; the carbohydrate and potassium chloride are uniformly ball-milled and mixed in a ball milling pot; after ball milling, the carbohydrate is easily wrapped on the surface of potassium chloride, and then high-temperature carbonization is performed under an inert gas, so that an acid liquor or an alkali liquor is not required when hard template potassium chloride is removed, and only water is required to dissolve and remove potassium chloride. The whole preparation process is green and pollution-free, and is applicable for industrial large-scale preparation.

Owner:JINING UNIV

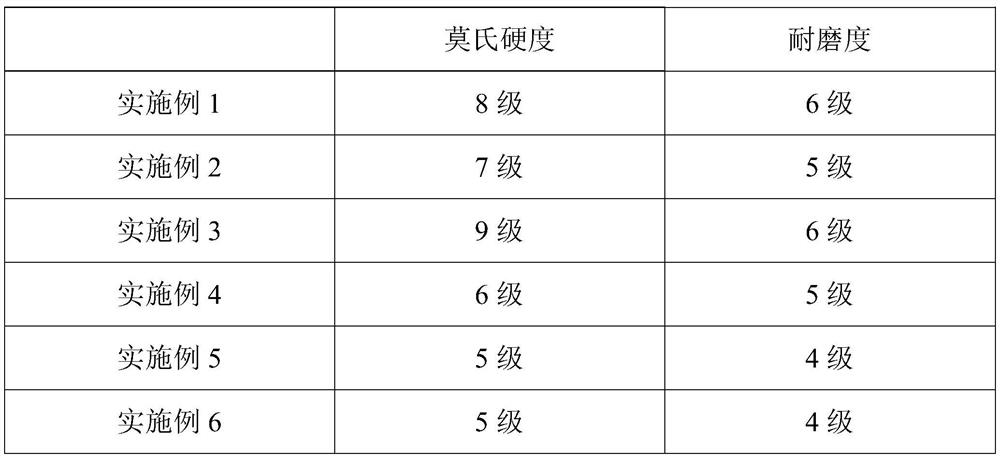

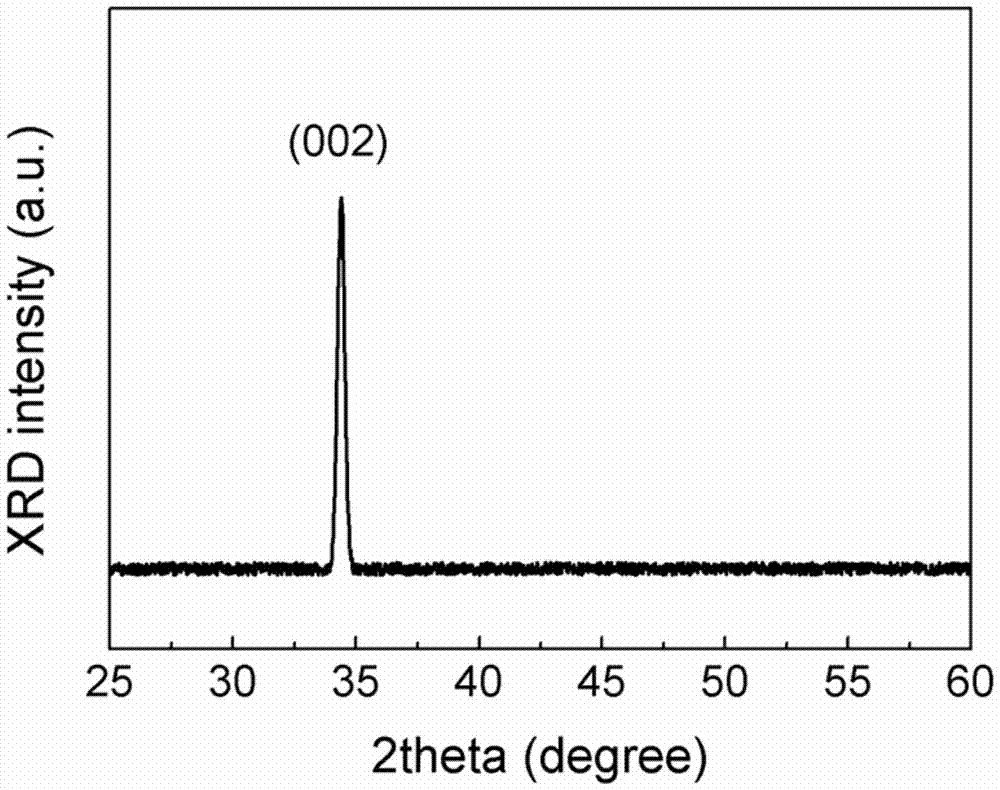

Dry granule, dry granule glaze, high-hardness and high-wear-resistance rock plate and preparation method thereof

PendingCN114804630AImprove hardness and wear resistanceEasy stepsCeramic materials productionPotassium feldsparCalcite

The invention discloses a dry granule, dry granule glaze, high-hardness and high-wear-resistance rock plate and a preparation method thereof, and belongs to the technical field of building rock plates, the dry granule, dry granule glaze, high-hardness and high-wear-resistance rock plate comprises the following raw materials by mass: 20-35% of potassium feldspar, 10-35% of quartz, 10-25% of calcite, 5-15% of barium carbonate, 5-20% of zinc oxide, 1-2% of alpha-Al2O3 nano powder, 6-15% of nano silica, and 15-20% of chitosan, the finally prepared high-hardness and high-wear-resistance ceramic rock plate glaze surface is high in hardness and wear-resistant, the Mohs hardness is more than level 5, the wear resistance is more than level 4, and the production cost is low; the preparation method of the high-hardness and high-wear-resistance rock plate provided by the invention is simple and convenient in steps and suitable for industrial large-scale preparation, and the sintering temperature is reduced by 300-500 DEG C compared with the sintering temperature of the existing high-hardness and high-wear-resistance rock plate.

Owner:佛山市利德嘉陶瓷制釉有限公司

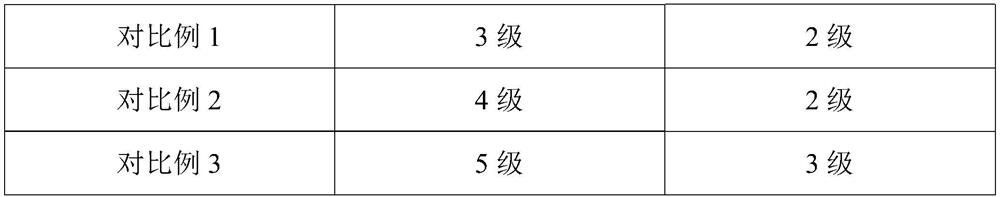

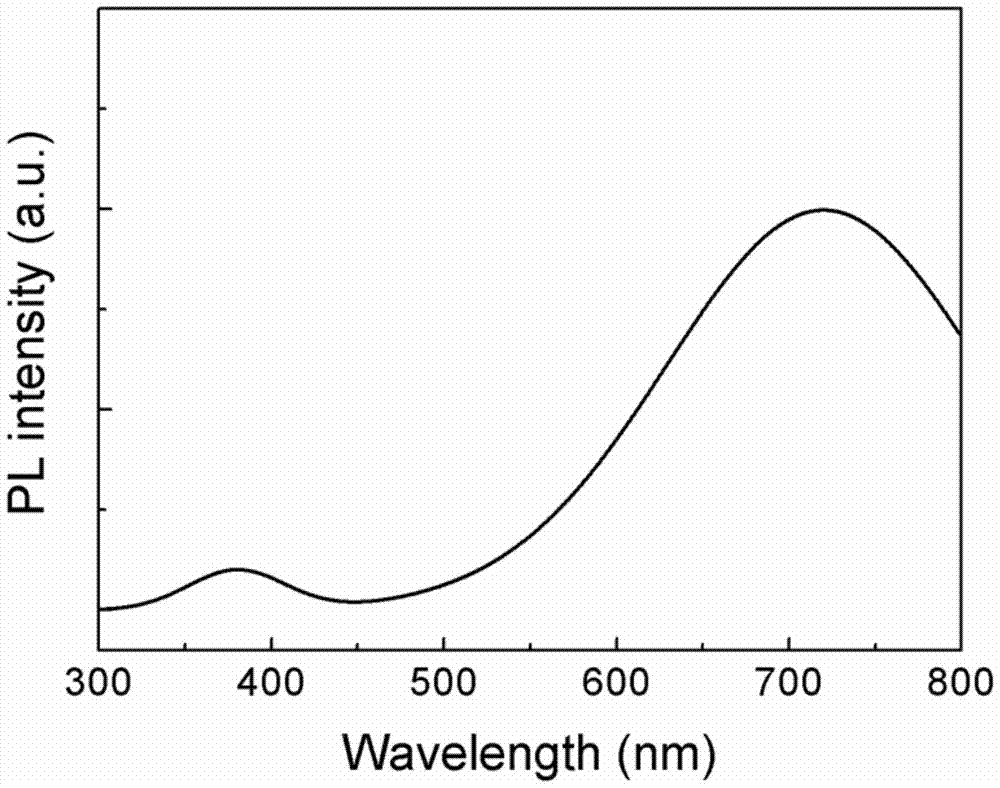

A kind of preparation method of the zno material of intense red light emission

InactiveCN105238393BHas strong luminous propertiesThe method is simple and safeLuminescent compositionsMicrowaveGreen band

The invention relates to a preparation method of a ZnO material emitting strong red light. The ZnO material is grown on a glass substrate and doped with copper, wherein the molar ratio of ZnO and Cu is 50:1. The preparation of the ZnO material The method comprises configuring a mixed precursor solution, synthesizing ZnO material by microwave from the precursor solution, and then heat-treating the ZnO material to obtain a ZnO material emitting strong red light; the normal luminescence peak of the ZnO material is located in the ultraviolet band near 380nm or 450-530nm Nearby blue-green band, and the ZnO material prepared by the present invention has strong luminescence characteristics in the red band of 720nm, and this strong red light emission provides a supplementary band of spectrum for white light modulation.

Owner:CHANGAN UNIV

A system and method for purifying industrial-grade lithium carbonate using high gravity

ActiveCN108975357BReduce distributionSuitable for industrial large-scale preparationAlkali metal carbonatesLithium carbonateCentrifugation

The invention discloses a system and method for purifying industrial-grade lithium carbonate by applying supergravity. The system includes a carbonizer, a solid-liquid separation device, a microwave-coupled supergravity device, and a centrifugal device sequentially connected through pipelines. The present invention combines supergravity technology, centrifugation and recovery devices to make the appearance and particle size distribution of the pyrolyzed lithium carbonate average, reduce the distribution of small particles and large particle solid products, and then adjust the centrifugal device according to the obtained particle size The size of the centrifugal force, and through centrifugation, most of the solid products with uniform particle size are completely precipitated, and on this basis, the clear liquid is refluxed through the recovery device, so that a small part of the small particles suspended in the clear liquid can pass through the heat of dissolution again. It can be decomposed and recycled, so that the battery-grade or high-purity lithium carbonate solid product with a yield reaching the industrial scale preparation standard can be obtained, which is suitable for industrial large-scale preparation.

Owner:BEIJING UNIV OF CHEM TECH

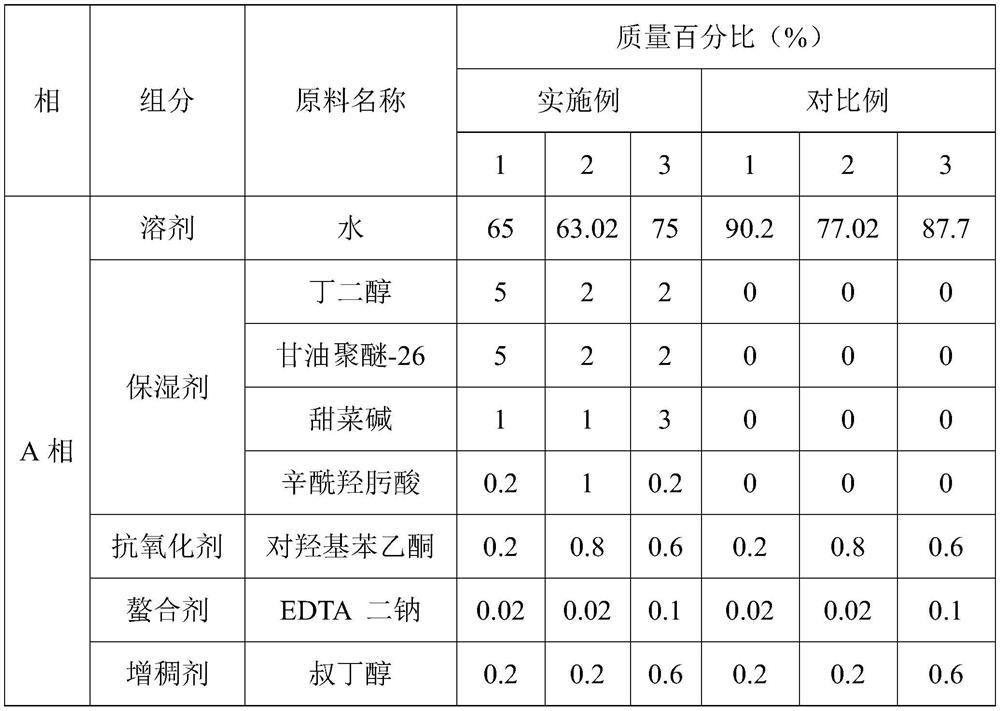

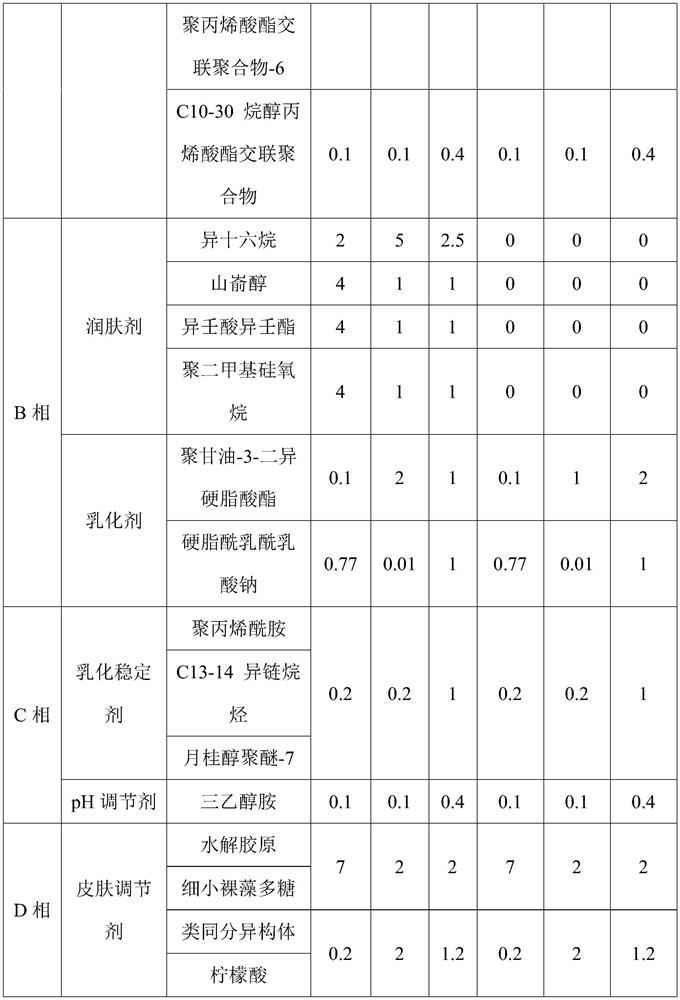

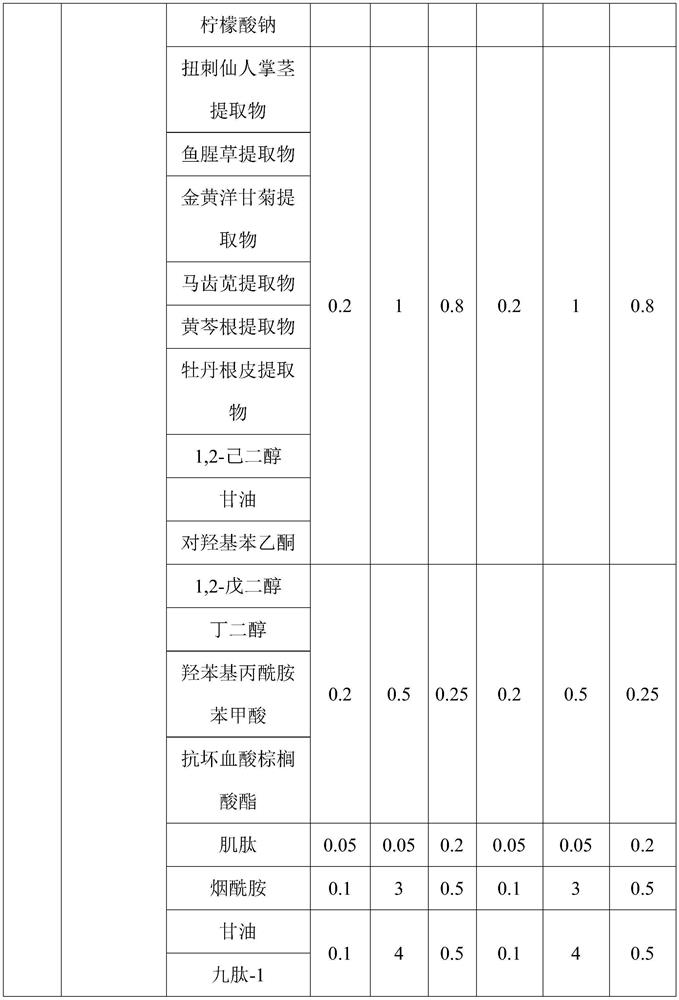

Composition for moistening skin and fading fine wrinkles and preparation method thereof

InactiveCN114366694ABrighten skin colourReduce churnCosmetic preparationsToilet preparationsPolymer scienceEmulsion

The invention discloses a composition for moistening skin and fading fine wrinkles and a preparation method thereof, and belongs to the technical field of cosmetics, the composition comprises the following raw materials in percentage by weight: a phase A: 65-75% of a solvent, 5-13% of a humectant, 0.2-0.8% of an antioxidant and 0.02-0.1% of a chelating agent; a phase B: 5-17% of an emollient and 1.11-6% of an emulsifier; a phase C: 0.2-1% of an emulsion stabilizer and 0.1-0.4% of a pH regulator; a phase D: 3.11 to 18.7 percent of a skin conditioner; the sum of the raw materials of the phase A, the phase B, the phase C and the phase D is 100%, the finally prepared composition for moistening the skin and fading the fine wrinkles has the effects of moisturizing and moistening the skin, the preparation method of the composition for moistening the skin and fading the fine wrinkles, provided by the invention, is simple and convenient in steps, mild in reaction condition and suitable for industrial large-scale preparation, and the composition also can keep activity.

Owner:程瑶

a mn 4+ Preparation method of ion-activated fluoride phosphor

ActiveCN109957400BReduced dosage requirementsHigh Luminescence Quantum YieldLuminescent compositionsLuminescence quantum yieldOptical property

The invention provides a preparation method of Mn<4+>-activated fluoride fluorescent powder. The preparation method provided by the invention does not need to form a saturated solution of A2MF6, so that the requirement of the use amount of raw materials is greatly reduced; in the preparation process, the target product can be synthesized at room temperature and is convenient to synthesize; a precipitating agent is added, so that the preparation is more convenient, the operation is simpler, the synthetic steps are simplified, and the prepared fluorescent powder has better optical properties; the fluoride fluorescent powder can be well excited by ultraviolet light to blue light, especially the blue light, and has strong red light emission, wherein the red light emission peak is in the wavelength range from 600 to 650 nm; the method has the advantages of a simple preparation process and short consumed time; and the prepared material has a high luminescence quantum yield and is suitable for industrial large-scale preparation.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Method for preparing solar cell absorber layer sb2se3 thin film based on magnetron sputtering and post selenization

InactiveCN106917068BImprove flatnessEasy to operateVacuum evaporation coatingSputtering coatingSputteringManufacturing technology

The invention discloses a method for preparing a solar cell absorption layer Sb2Se3 film based on magnetron sputtering and post-selenization. The method is characterized in that a substrate is one of a molybdenum plating film, conductive glass, soda-lime glass, silica glass and metal foil; the purity of a magnetron sputtering Sb2Se3 target material is 96-99.9%; the Sb2Se3 target material is deposited on the cleaned substrate in argon atmosphere through magnetron sputtering, and a Sb2Se3 precursor film is formed and stored in vacuum environment; the Sb2Se3 precursor film is subjected to selenylation heat treatment in selenium atmosphere, and finally the Sb2Se3 film is obtained. The preparation method of carrying out heat treatment in selenium atmosphere after carrying out magnetron sputtering on the Sb2Se3 precursor film has the advantages that the synthesized film phase is pure and single, the manufacturing technology is simple, safe and nontoxic, large-area production can be achieved, and the thickness is easy to control.

Owner:FUJIAN NORMAL UNIV

Surface modification method of fluoride luminescent material and fluoride luminescent material prepared therefrom

ActiveCN111171815BImprove corrosion resistanceReduce surface defectsEnergy efficient lightingLuminescent compositionsQuantum yieldPhosphoric Acid Esters

Owner:XIAMEN INST OF RARE EARTH MATERIALS

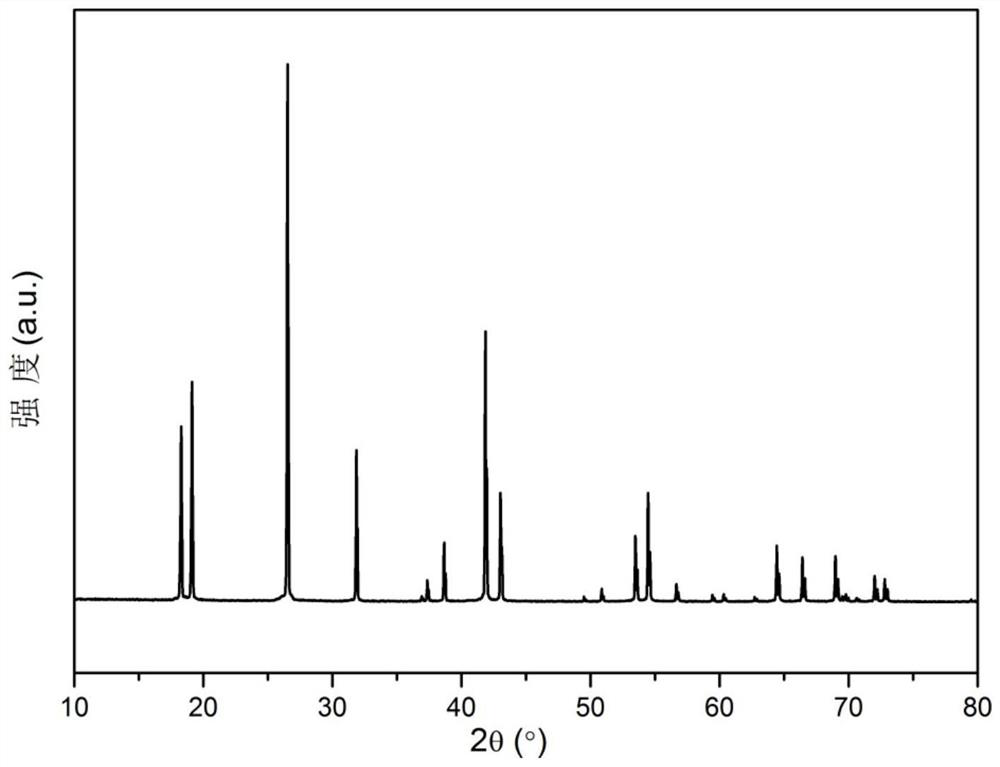

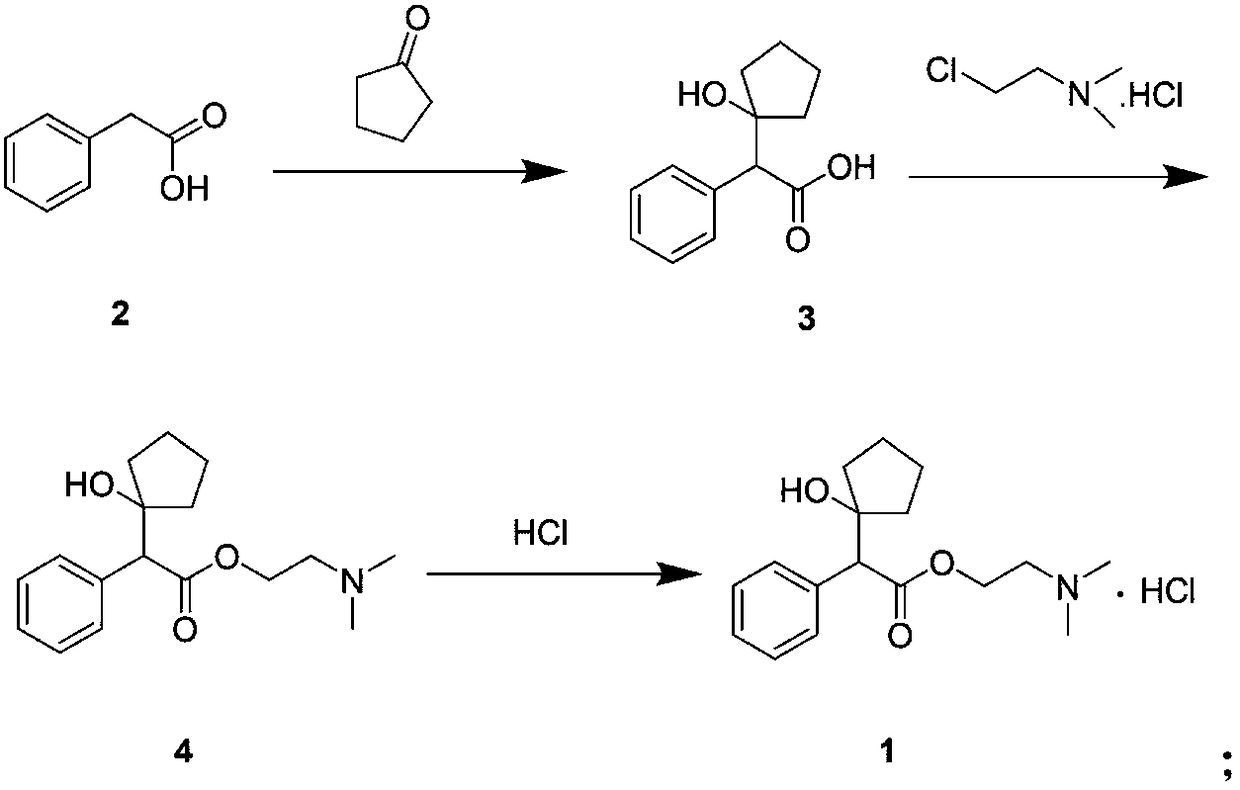

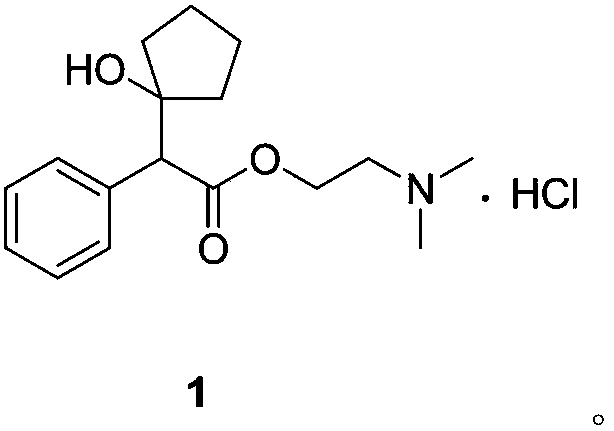

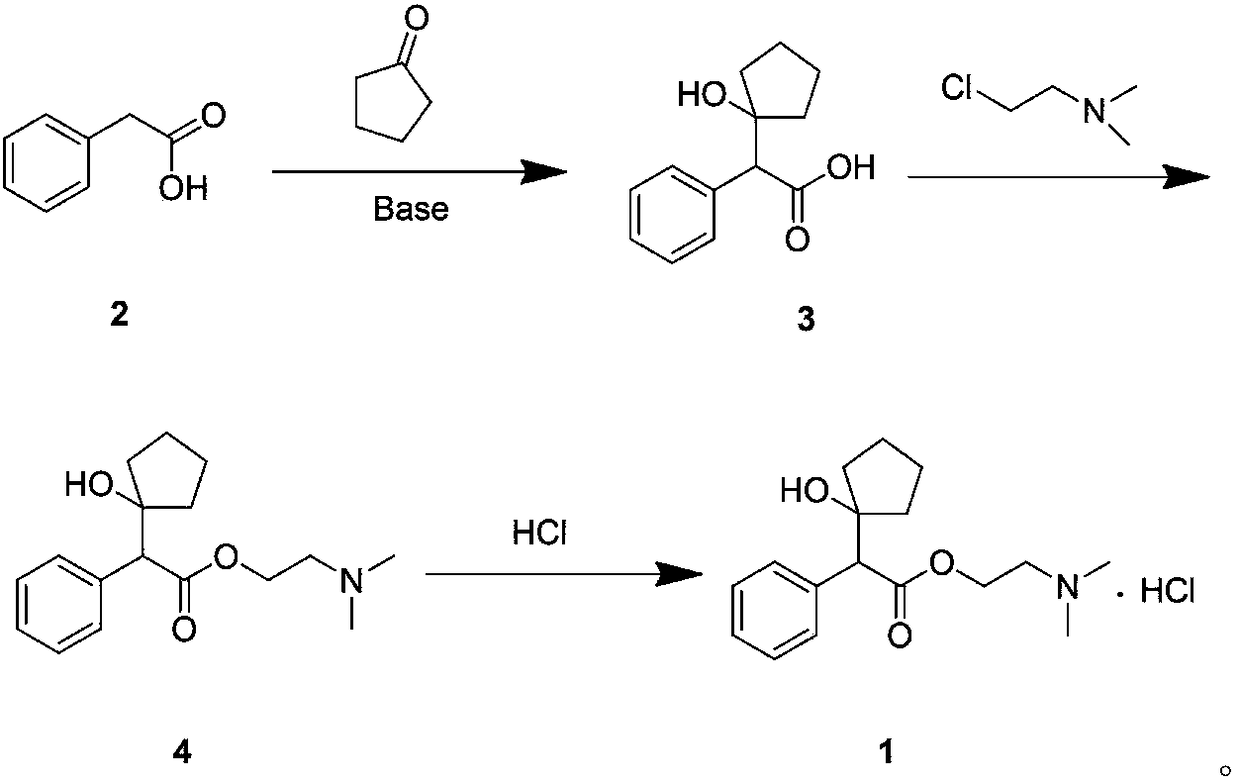

A kind of preparation method of cyclopentolate hydrochloride

ActiveCN106083615BMild reaction conditionsEasy to operateOrganic compound preparationCarboxylic compound preparationBenzeneAcetic acid

The invention relates to a preparation method of an M-type cholinoceptor blocker cyclopentolate hydrochloride. The preparation method comprises that phenylacetic acid as an initial raw material and cyclopentanone undergoes a reaction to produce 2-(1-hydroxycyclopentyl)-phenylacetic acid (as intermediate 3), the 2-(1-hydroxycyclopentyl)-phenylacetic acid undergoes a replacement reaction and the reaction product undergoes a salification reaction to produce cyclopentolate hydrochloride. The preparation method can be operated simply, is safe and controllable, has low labor protection demands and is suitable for industrial production.

Owner:SHANDONG ACADEMY OF PHARMACEUTICAL SCIENCES +1

a kind of abx 3 Preparation method of type all-inorganic perovskite nanocrystal

ActiveCN110194954BReduce dosageLow unit priceNanoopticsLuminescent compositionsQuantum yieldNanowire

The invention discloses a preparation method of an ABX3 type all-inorganic perovskite nanocrystal. In the preparation process, a solvent is used in a small amount, and the raw material unit price is low (for example, an expensive PbX2 raw material is replaced by cheap lead acetate), environmental requirements are not high in the preparation process, a glove box is not required, the operation procedure is simple, and the cost of raw materials and instruments is greatly reduced. The nanocrystal can synthesize a target product in a wide temperature range of 0 to 300 DEG C in the preparation process, and the morphology, phase, size and luminous performance of the nanocrystal can be controlled by changing the raw material ratio, solvent ratio, reaction temperature and / or reaction time, for example, perovskite nanowires can be prepared at the reaction temperature of greater than or equal to 0 DEG C and less than 90 DEG C, and perovskite quantum dots can be prepared at the reaction temperature of 90 to 300 DEG C. The nanocrystal has good stability and high fluorescence quantum yield (26%-80%), and can realize full visible spectrum (400-700 nm) luminescence. The preparation method is simple in process, short in time consumption, low in cost, easy to amplify and synthesize, and suitable for industrial large-scale preparation.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

A preparation method of carbon nitride ultrathin sheet with adjustable atomic layer number

ActiveCN107324297BIncrease layer spacingFast processMaterial nanotechnologyPhysical/chemical process catalystsOrganic solventCarbon nitride

The invention relates to a preparation method with adjustable number of carbon nitride atomic layers. Weighing 3 to 9 g Bulk g‑C 3 N 4 Rapidly heat the container to 550-580°C for thermal expansion for 10-20 minutes, then take it out, immediately add liquid nitrogen to immerse the sample, and wait until the LN 2 After volatilization is completed, repeat the above steps 5 to 10 times to obtain ultra-thin flakes; Preparation of carbon nitride ultra-thin flakes: Weigh 0.12-1.2g of g‑C obtained in step (1) 3 N 4 The ultra-thin sheet is rapidly heated to a TE temperature of 550-580°C in a container, and then naturally cooled to room temperature after being kept for 10-20 minutes to obtain single atomic layer and multi-layer g-C 3 N 4 . The advantage of this invention is that it uses cheap, non-toxic stripping reagents to replace the commonly used ultrasonic stripping method of organic reagents, making it easier to prepare g-C 3 N 4 The ultrathin wafer process is fast, low-cost, environmentally friendly, and suitable for industrial large-scale preparation.

Owner:武汉莱瑞医疗科技有限公司

An efficient and stable mn 4+ Doped fluoride light-emitting material and preparation method thereof

ActiveCN109423276BAvoid degradationImprove luminous efficiencyLuminescent compositionsPhysical chemistryMoisture resistance

The invention discloses a highly efficient and stable modified Mn 4+ Doped fluoride luminescent material and preparation method thereof, the preparation method can efficiently synthesize A in the temperature range of 0-120°C 2 MF 6 compound coated A 2 MF 6 :Mn 4+ Fluoride phosphors, avoid Mn 4+ It degrades directly in contact with the external environment, has high temperature stability and good moisture resistance, and further improves the luminous efficiency of the phosphor. The method has low preparation temperature, short time and easy process control, and is suitable for industrial large-scale preparation.

Owner:XIAMEN INST OF RARE EARTH MATERIALS

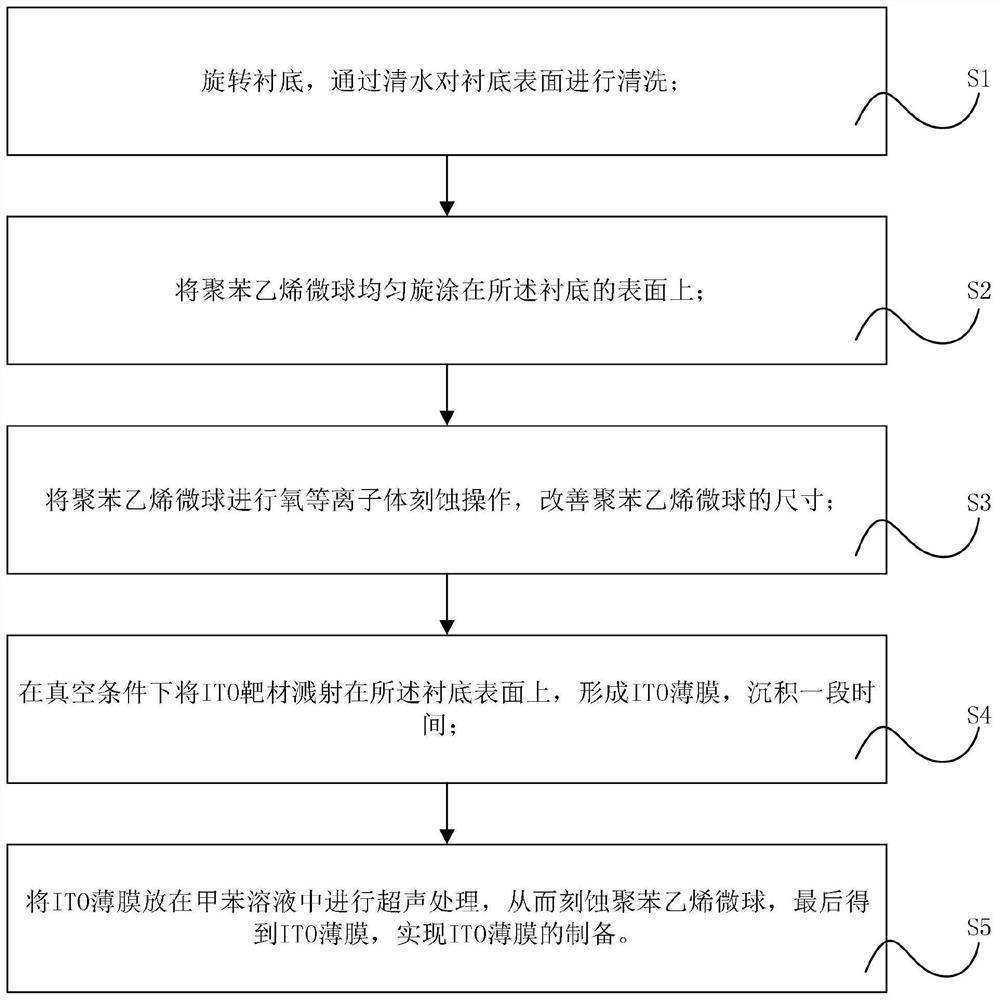

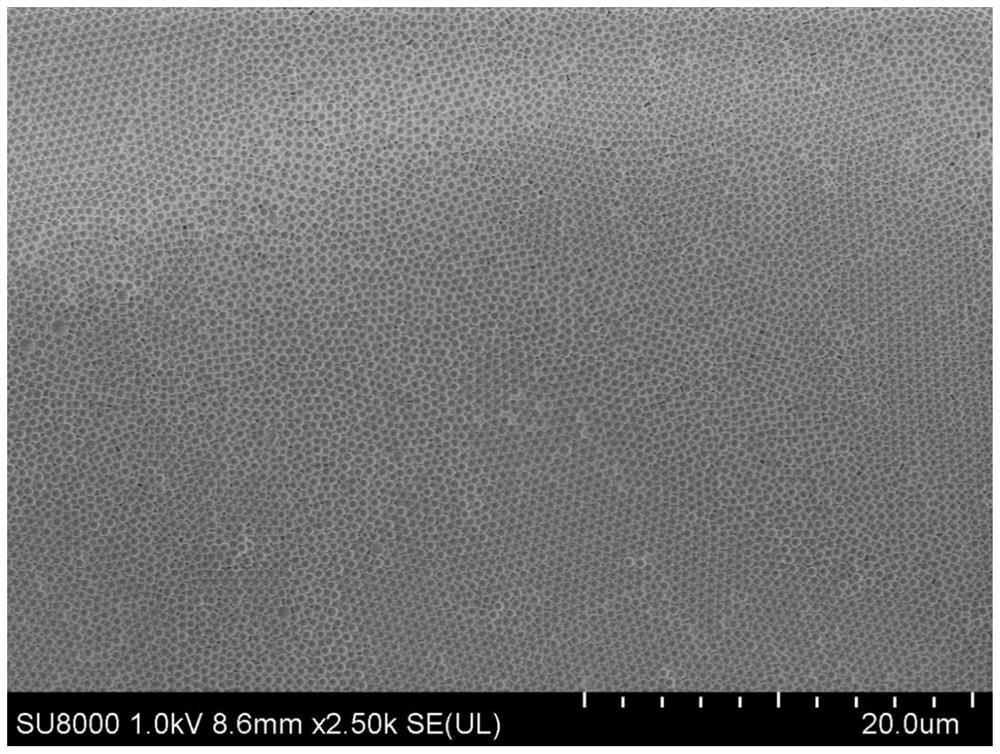

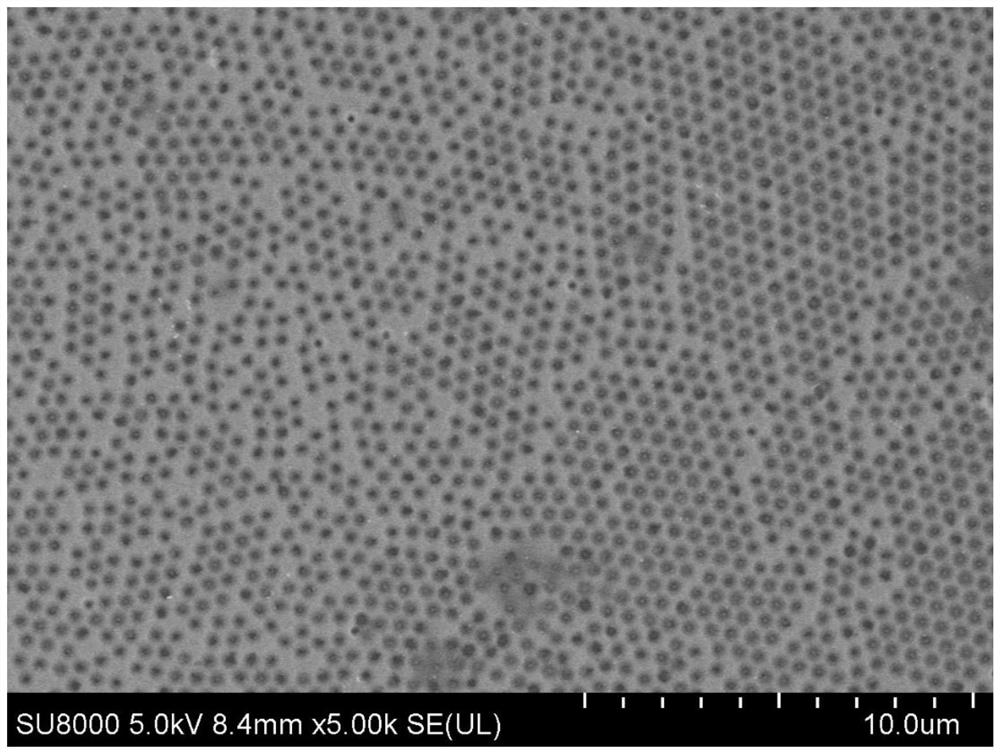

Method for preparing ITO (Indium Tin Oxide) film based on magnetron sputtering and etching treatment

PendingCN114318264AImprove transmittanceStrong resistance to tensile stressVacuum evaporation coatingSputtering coatingMicrosphereFilm base

The invention provides a method for preparing an ITO film based on magnetron sputtering and etching treatment, and the method comprises the following steps: S1, rotating a substrate, and cleaning the surface of the substrate through clean water; s2, uniformly spin-coating polystyrene microspheres on the surface of the substrate; s3, performing oxygen plasma etching operation on the polystyrene microspheres to improve the sizes of the polystyrene microspheres; s4, sputtering an ITO target material on the surface of the substrate under a vacuum condition to form an ITO thin film, and depositing for a period of time; and step S5, putting the ITO film in a toluene solution for ultrasonic treatment so as to etch the polystyrene microspheres, and finally obtaining the ITO film, thereby realizing the preparation of the ITO film.

Owner:福建富兰光学股份有限公司

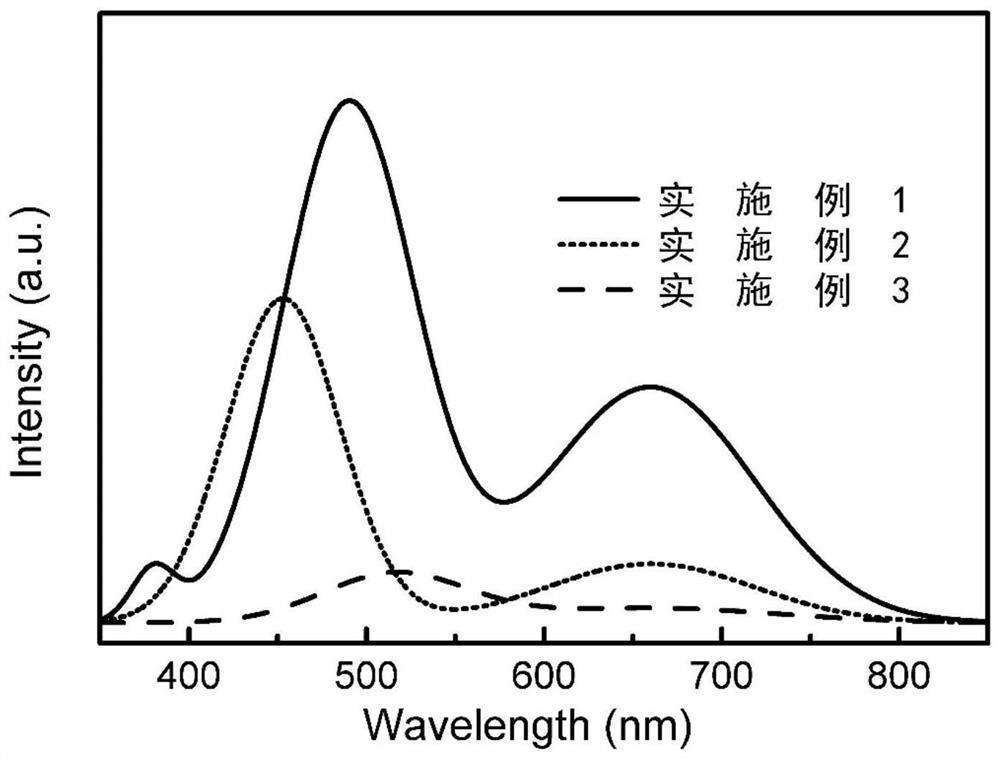

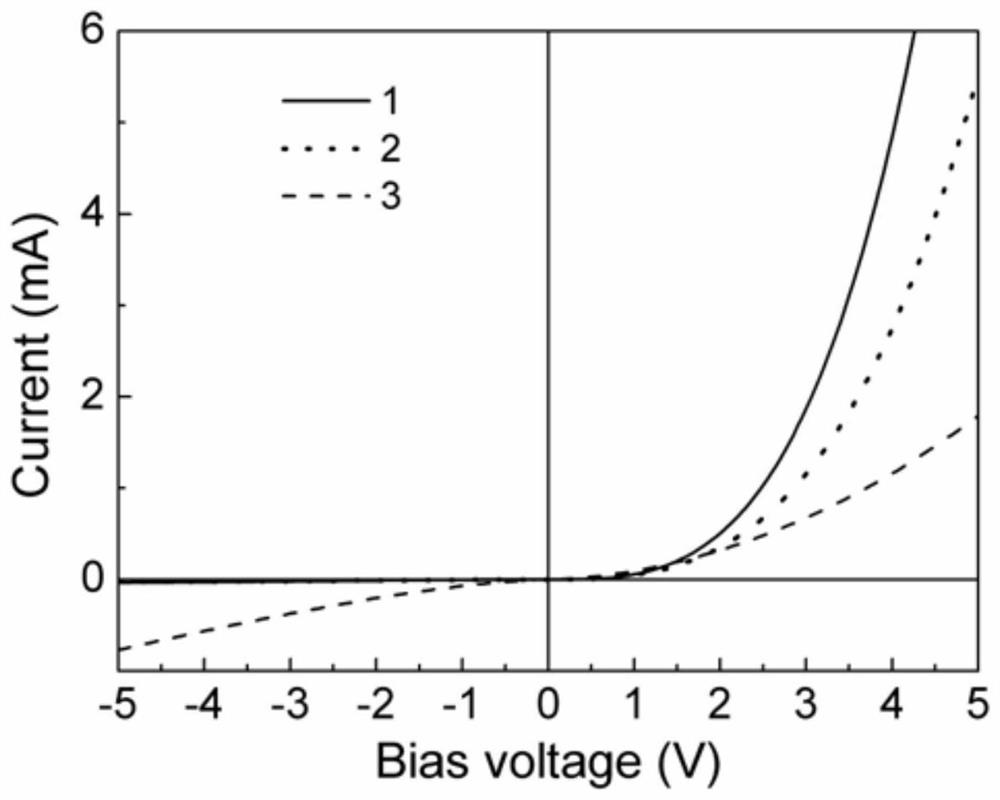

A kind of LED containing pmot:ppv/zno:cu/zno:al heterojunction and its preparation method

ActiveCN110783472BBeneficial photobiological effectsImprove securitySolid-state devicesSemiconductor/solid-state device manufacturingHeterojunctionCopper nitrate

The invention discloses a method for preparing an LED containing a PMOT:PPV / ZnO:Cu / ZnO:Al heterojunction, which is characterized in that it comprises growing a ZnO:Cu / ZnO:Al heterojunction on an ITO substrate, and The mixed solution of PMOT and PPV is spin-coated on the surface of the ZnO:Cu polycrystalline layer of ZnO:Cu / ZnO:Al heterojunction for heat treatment, and finally is coated with a Ti electrode on the surface of the ZnO:Cu polycrystalline layer to obtain final product; The growth of ZnO:Cu / ZnO:Al heterojunction on the ITO substrate includes firstly growing the ZnO:Al polycrystalline layer on the ITO substrate, and then putting it into the mixed solution of zinc acetate and copper nitrate, in ZnO:Al A ZnO:Cu polycrystalline layer is grown on the surface of the polycrystalline layer, and finally, a ZnO:Cu / ZnO:Al heterojunction is obtained on the ITO substrate. The invention realizes the main luminous peak of 490nm through spectral modulation based on semiconductor energy band engineering, and can provide more excellent photobiological effects. The preparation method of the invention is simple and safe in process, and the equipment and raw materials used are cheap, and is suitable for industrialized large-scale preparation.

Owner:CHANGAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com