Fibrous perovskite solar cell and preparation method and application thereof

A technology of solar cells and perovskites, applied in the field of solar cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

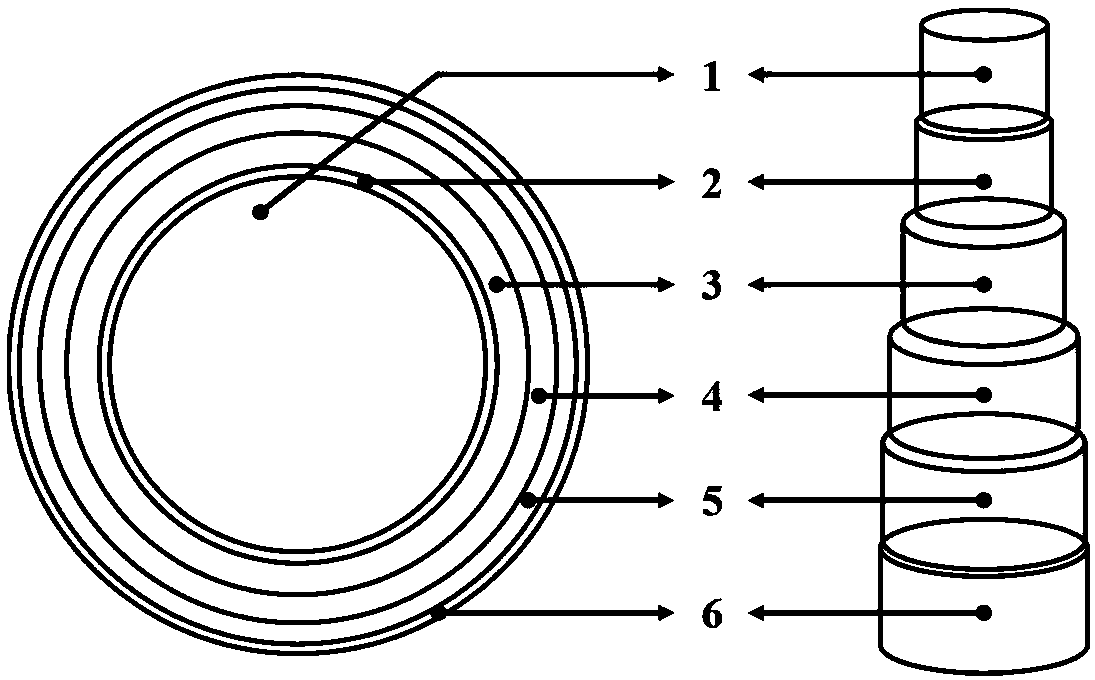

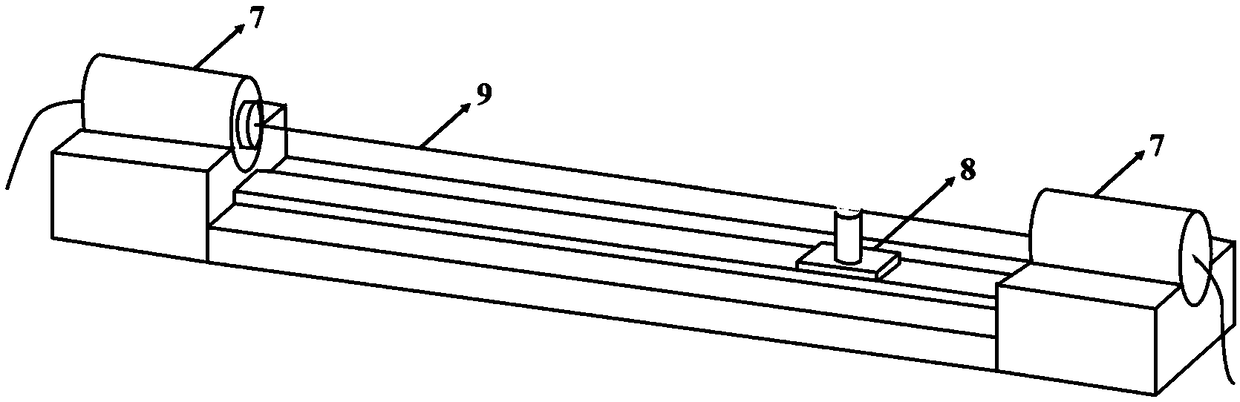

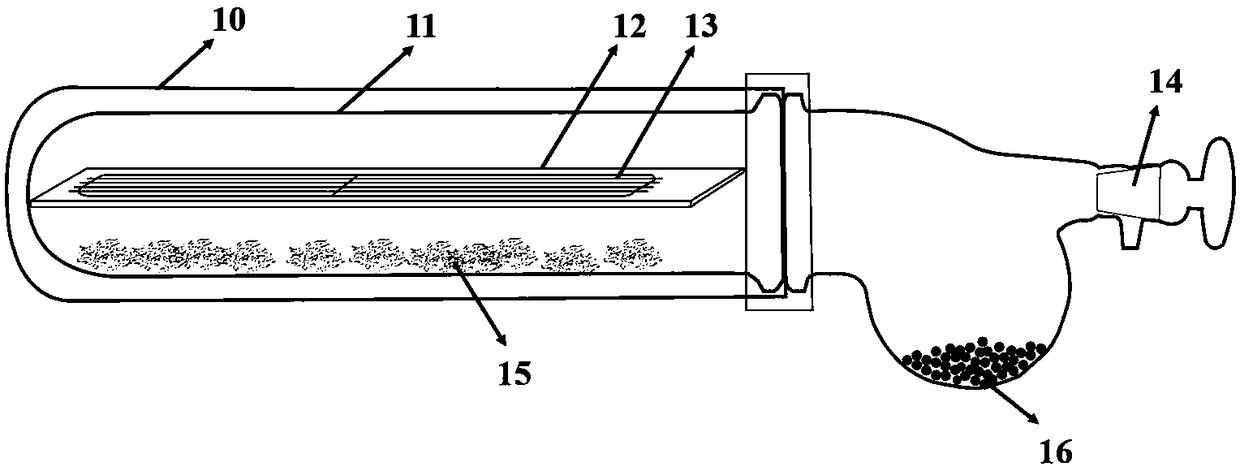

[0074] A titanium wire with a diameter of 250 nm and a purity of 99.9% was taken, polished with 5000-mesh sandpaper, and then ultrasonically cleaned with acetone and ethanol in sequence. fixed at figure 2 On the wire coating machine shown, the electric heating temperature is 500° C., and the heating time is 1 min, and the titanium dioxide dense layer is prepared in situ. Dilute 18NR-T commercial titanium dioxide slurry by adding 6.5 times the mass of ethanol to make titanium dioxide colloid; figure 2 On the wire coating machine shown, the titanium wire is heated to 120°C, the rotation speed of the titanium wire in the radial direction is 0.5r / s, and the titanium dioxide colloid is loaded on the figure 2 The speed-adjustable moving base 8 on the wire coating machine shown was made to move at a speed of 0.5 cm / s in the axial direction of the titanium wire, and coated 10 times to prepare a titanium dioxide porous layer. Use DMF as a solvent to prepare PbI with a concentration o...

Embodiment 2

[0078] A titanium wire with a diameter of 250 nm and a purity of 99.9% was taken, polished with 5000-mesh sandpaper, and then ultrasonically cleaned with acetone and ethanol in sequence. fixed at figure 2 On the wire coating machine shown, the electric heating temperature is 500° C., and the heating time is 1 min, and the titanium dioxide dense layer is prepared in situ. Dilute the 18NR-T commercial titanium dioxide slurry by adding 8 times the mass of ethanol to make titanium dioxide colloid; figure 2 On the wire coating machine shown, the titanium wire is heated to 120°C, the rotation speed of the titanium wire in the radial direction is 0.5r / s, and the titanium dioxide colloid is loaded on the figure 2 The speed-adjustable mobile base 8 on the wire coating machine shown was made to move at a speed of 2 cm / s in the axial direction of the titanium wire, and coated 8 times to prepare a titanium dioxide porous layer.

[0079] Use DMF:DMSO=5:1 (mass ratio) as a mixed solvent, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com