Filler for a supergravity rotation bed, preparation method and uses thereof

A supergravity rotating bed, wire mesh packing technology, applied in chemical instruments and methods, chemical/physical/physical chemical processes, chemical/physical processes, etc., can solve the problems of limited improvement in mass transfer effects, and achieve strong surface adhesion. , The effect of uniform film thickness and high erosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A preparation method for a high-gravity rotating bed filler, comprising the steps of:

[0045] 1) The corrugated stainless steel wire mesh with a hole diameter of 1.62mm, a wire diameter of 0.5mm, and a mesh number of 10 was sandblasted for 40 minutes to remove surface impurities;

[0046] 2) At room temperature, use the PTFE fluororesin coating as the primer and spray the suspended emulsion evenly on the metal mesh of the straight stainless steel wire mesh with a spray gun under a balanced wind pressure of 0.6MPa;

[0047]3) Under the action of static electricity, polytetrafluoroethylene powder is adsorbed on the surface of the straight stainless steel wire mesh packing, the adsorption thickness is 15-25 μm, and then dried and cured at 350 ° C for 30 minutes, forming on the surface of the straight stainless steel wire mesh packing Hydrophobic film, high dispersibility of liquid for high-gravity rotating bed packing.

[0048] The physical picture of the filler is shown...

Embodiment 2

[0055] A preparation method for a high-gravity rotating bed filler, comprising the steps of:

[0056] 1) Sand blast the 10-mesh flat stainless steel wire mesh for 40 minutes to remove surface impurities;

[0057] 2) At room temperature, use the PFA paint as the primer and spray the suspended emulsion evenly on the straight stainless steel wire mesh metal mesh with a spray gun under a balanced wind pressure of 0.6MPa;

[0058] 3) Under the action of static electricity, the PFA powder is adsorbed on the surface of the stainless steel wire mesh packing, the adsorption thickness is 15-25 μm, and then dried and solidified at 380 ° C for 40 minutes to form a hydrophobic film on the surface of the stainless steel mesh packing, and the Filler for liquid high-dispersion high-gravity rotating bed.

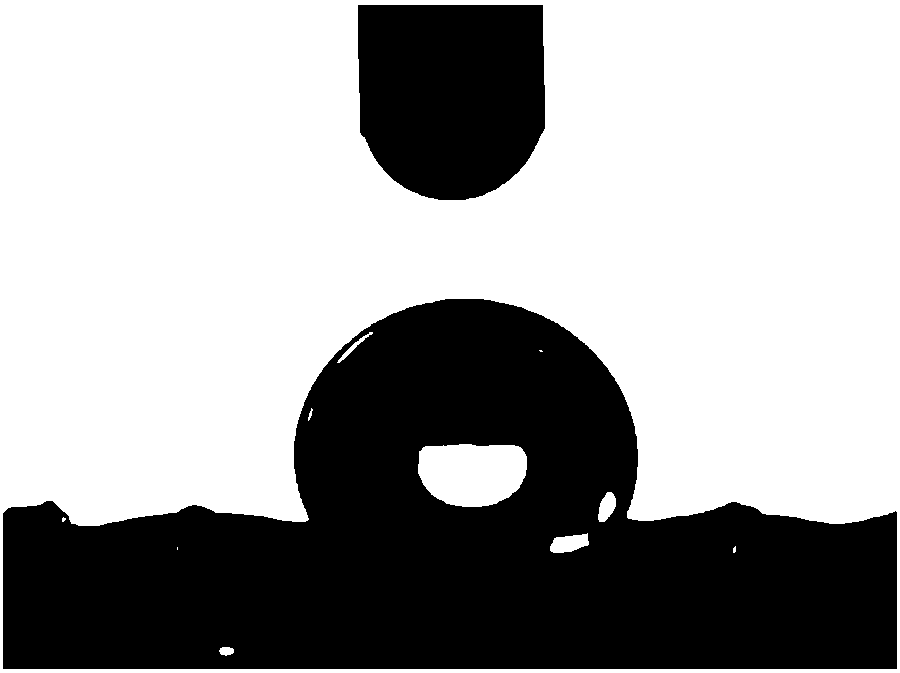

[0059] The film structure on the surface of the filler is dense and uniform, and the contact angle is 124°. Compared with the unmodified straight stainless steel wire mesh, the surface hydr...

Embodiment 3

[0064] A preparation method for a high-gravity rotating bed filler, comprising the steps of:

[0065] 1) The 40-mesh flat stainless steel wire mesh was sandblasted for 45 minutes to remove surface impurities;

[0066] 2) At room temperature, use the ETFE paint as the primer and spray the suspended emulsion evenly on the straight stainless steel wire mesh metal mesh with a spray gun under a balanced wind pressure of 0.8MPa;

[0067] 3) The ETFE powder is adsorbed on the surface of the stainless steel wire mesh filler under the action of static electricity, and the adsorption thickness is 15-25 μm, and then dried and solidified at 380 ° C for 40 minutes to form a hydrophobic film on the surface of the stainless steel wire mesh filler to obtain Filler for liquid high-dispersion high-gravity rotating bed.

[0068] The film structure on the surface of the filler is dense and uniform, and the contact angle is 120°. Compared with the unmodified straight stainless steel wire mesh, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specification | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com