Preparation method of carbon nanocage material

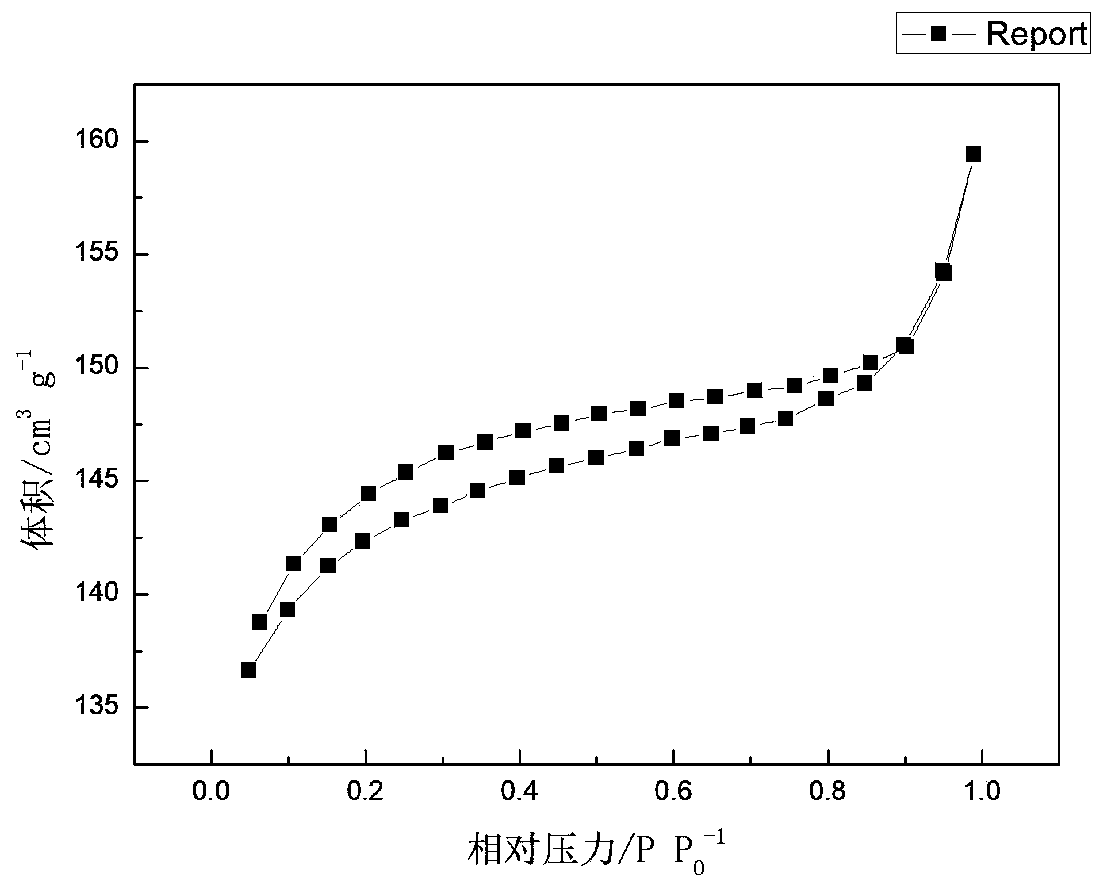

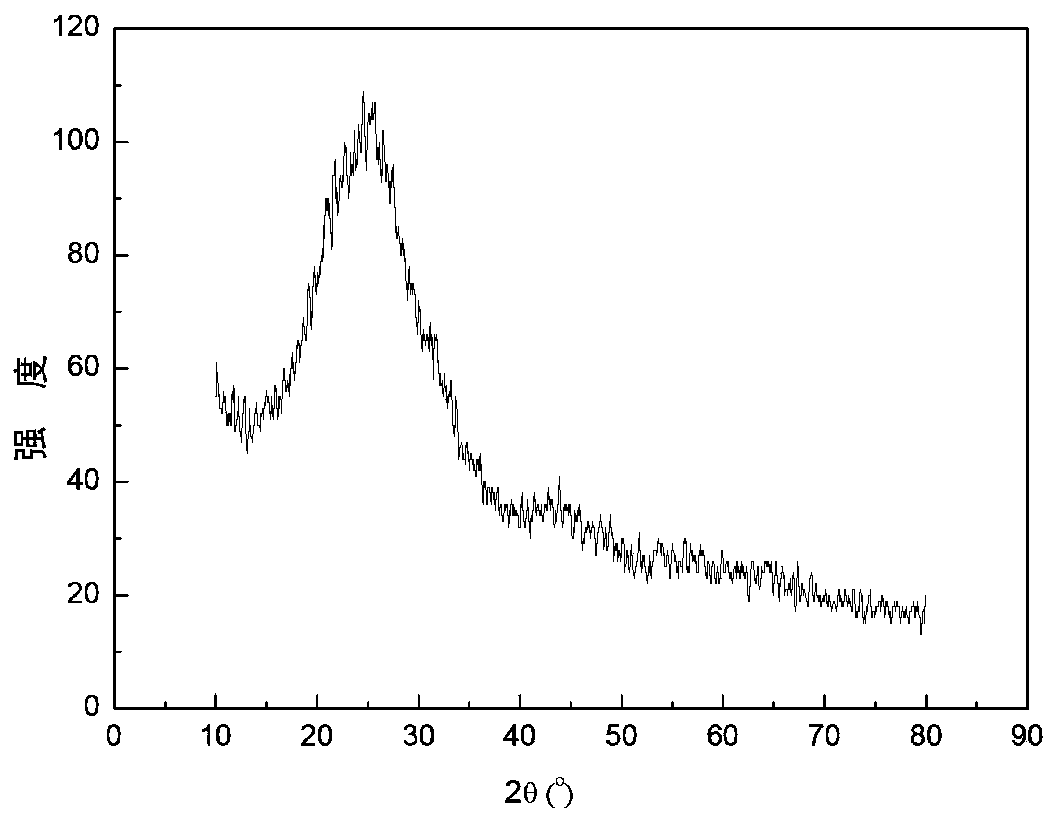

A carbon nanocage and weighing technology, which is applied in the direction of nano-carbon, can solve the problems of complex process, high cost, strong corrosion and toxicity of reagents, etc., and achieve high specific surface area, good conductivity, and good electrolyte ion transport performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

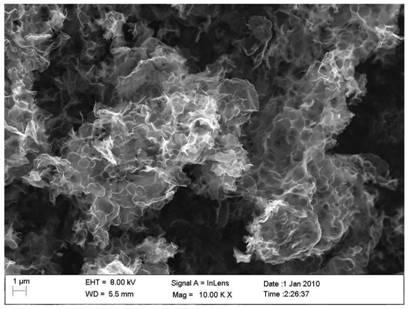

[0027] Weigh 2g of sucrose and 10g of potassium chloride into a polytetrafluoroethylene ball mill tank, and then weigh 100g of agate balls into the ball mill tank, and ball mill for 4 hours. Put the ball-milled solid powder in a quartz boat, and then put it into a tube furnace equipped with a quartz tube; pass nitrogen inert gas, the flow rate of the inert gas in the tube furnace is 50 mLmin -1 , Then at 5℃min -1 The temperature is raised to 800 ℃ at the rate of temperature increase, and the high temperature carbonization holding time is 2 hours to obtain the initial product. The obtained initial product was immersed in hot water for 8 hours, then filtered by suction, and dried in an oven at 80° C. for 24 hours to obtain a carbon nanocage material.

Embodiment 2

[0029] Weigh 1g of sucrose and 18g of potassium chloride into a polytetrafluoroethylene ball mill tank, then weigh 50g of agate balls into the ball mill tank, and ball mill for 0.5h. Put the ball-milled solid powder in a quartz boat, and then put it into a tube furnace equipped with a quartz tube; pass nitrogen inert gas, the flow rate of the inert gas in the tube furnace is 60 mLmin -1 , Then at 10℃min -1 The temperature is raised to 700 ℃ at the rate of temperature increase, and the high temperature carbonization holding time is 4 hours to obtain the initial product. The obtained initial product was immersed in hot water for 10 hours, then filtered with suction, and dried in an oven at 80° C. for 24 hours to obtain a carbon nanocage material.

Embodiment 3

[0031] Weigh 2g glucose and 1g potassium chloride into a polytetrafluoroethylene ball mill pot, then weigh 200g agate balls into the ball mill pot and ball mill for 4 hours. Put the ball-milled solid powder in a quartz boat, and then put it into a tube furnace equipped with a quartz tube; pass nitrogen inert gas, and the flow rate of the inert gas in the tube furnace is 80 mLmin -1 , Then at 5℃min -1 The temperature is raised to 600°C at the rate of temperature increase, and the high-temperature carbonization holding time is 2h to obtain the initial product. The obtained initial product was immersed in hot water for 8 hours, then filtered by suction, and dried in an oven at 80° C. for 24 hours to obtain a carbon nanocage material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com