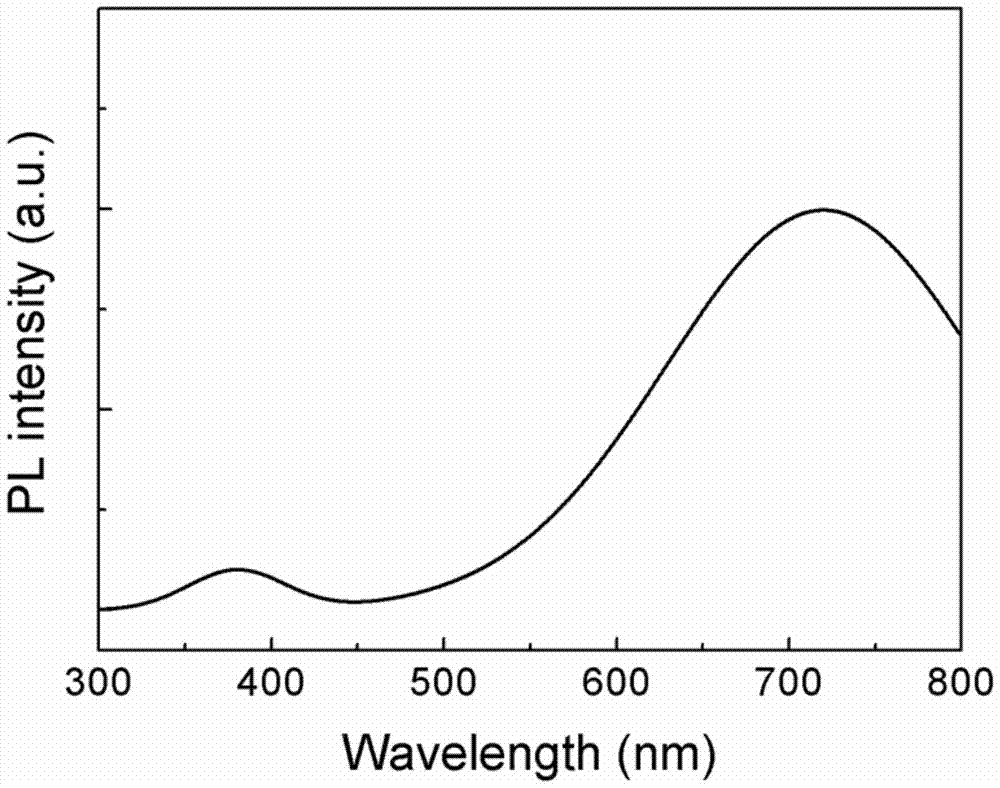

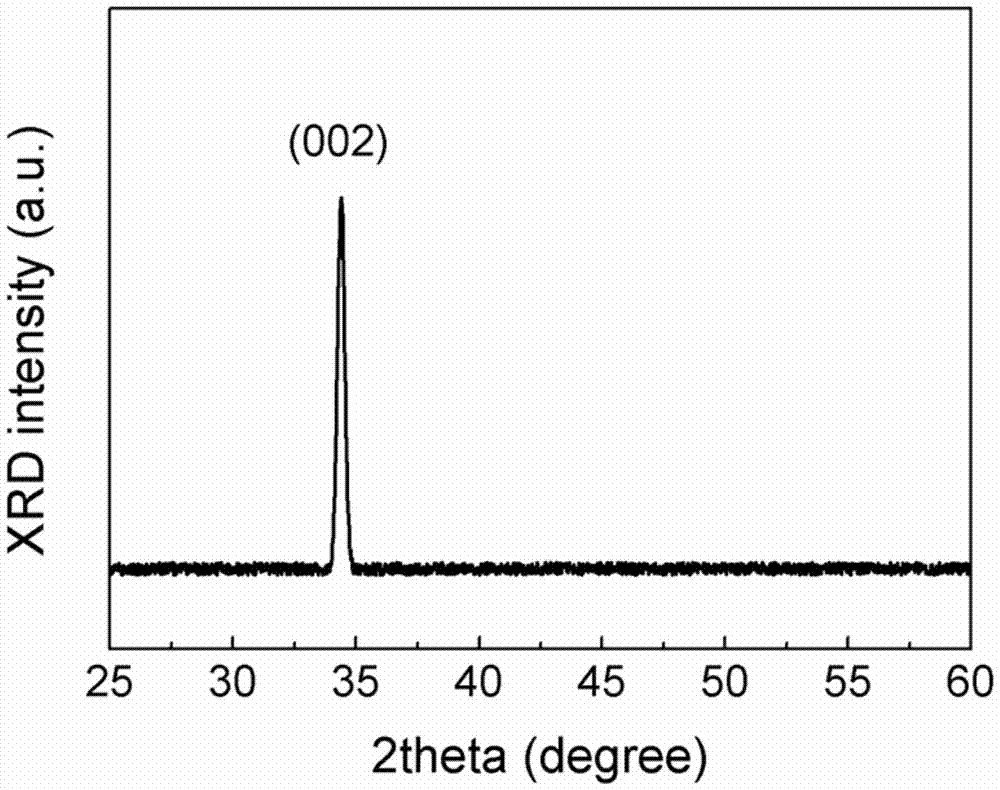

A kind of preparation method of the zno material of intense red light emission

A technology of red light and raw materials, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of high price of ZnO bulk single crystal and inability to promote it on a large scale, and achieve the effect of low price, simple and safe method process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Step 1: Prepare a mixed solution of zinc nitrate, copper nitrate, ammoniacal liquor and triethanolamine, wherein the zinc nitrate concentration is 0.05mol / L, the copper nitrate concentration is 1mmol / L, the ammoniacal liquor concentration is 0.05mol / L, and the triethanolamine concentration is 0.01mol / L. After the solution is prepared, mix it evenly in the beaker;

[0023] Step 2: Place the glass sheet in an ultrasonic cleaning machine for treatment. The treatment solutions are toluene, acetone, carbon tetrachloride, ethanol and deionized water in sequence. Each solution is treated for 5 minutes. After the treatment is completed, it is dried with high-purity nitrogen;

[0024] Step 3: Place the treated glass piece obliquely in the beaker where the above solution is placed, put the beaker into a microwave oven and heat it with microwaves, the microwave power is 500W, and the heating time is 2 hours. After the process is over, a layer of doped Cu ZnO material;

[0025] ...

Embodiment 2

[0029] The preparation method and test are the same as in Example 1, but no copper nitrate solution is added in step 1. Table 1 shows the normalized relative intensity of the red light peak in the PL spectrum prepared in this example. It can be seen from Table 1 that the ZnO material in this example has almost no red light emission.

Embodiment 3

[0031] The preparation method and test are the same as in Example 1, but no ammonia solution is added in step 1. Table 1 shows the normalized relative intensity of the red light peak in the PL spectrum prepared in this example. It can be seen from Table 1 that the red light emission intensity of the ZnO material in this example is worse than that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com