Metal organic framework material and preparation method thereof

A metal-organic framework and reaction technology, applied in separation methods, chemical instruments and methods, and other chemical processes, can solve problems such as complex processes and high energy consumption, and achieve the effect of improving separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

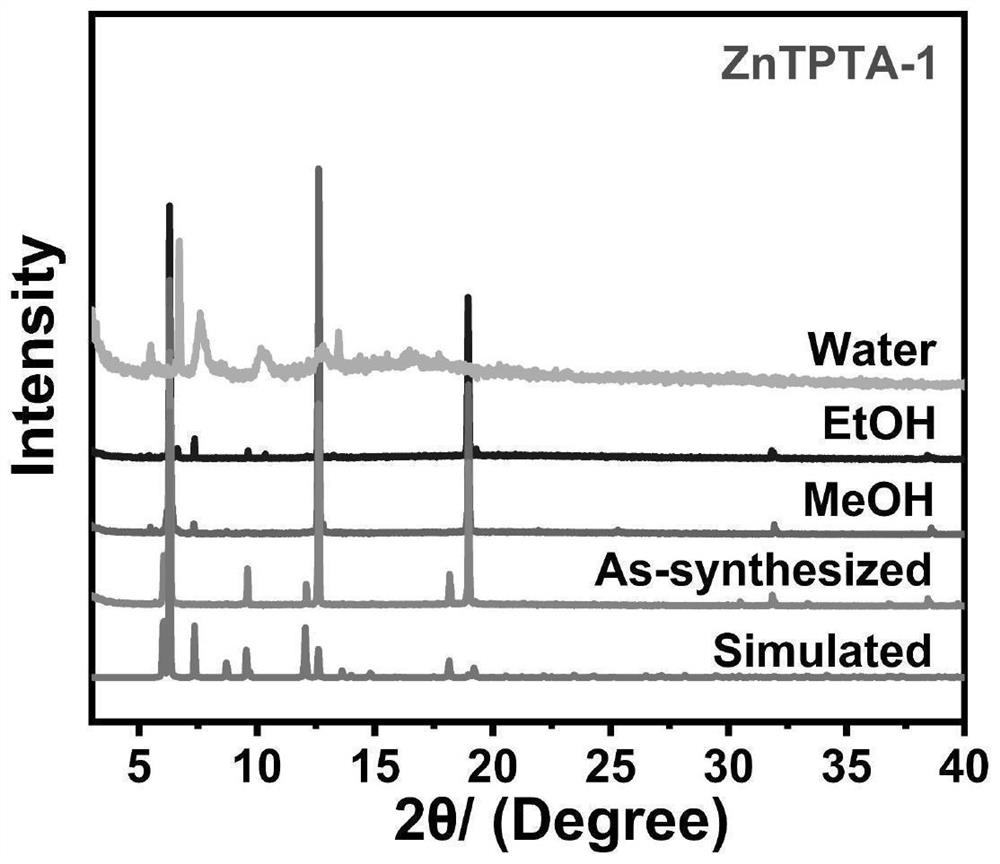

Embodiment 1

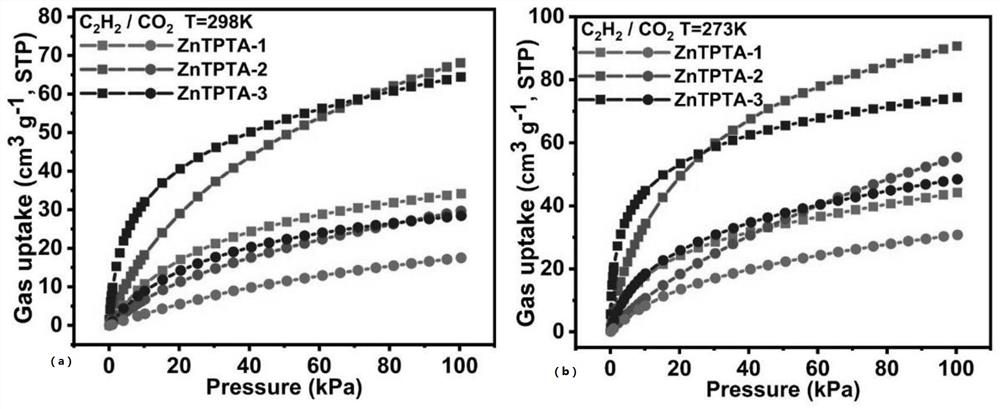

[0038] Metal-organic framework material, the chemical formula is {[Zn 2 (TPTA)(bpy)](CH 3 CN)(DMF) 2 };

[0039] The above {[Zn 2 (TPTA)(bpy)](CH 3 CN)(DMF) 2 The preparation method of } specifically comprises the following steps:

[0040] (1) Zn(NO 3 ) 3 ·6H 2 O (8 mg, 0.022 mmol), H 4 TPTA (3 mg, 0.0074 mmol), bpy (3 mg, 0.019 mmol) were dissolved in 0.5 mL CH 3 In a mixed solvent of CN and 1.5 mL of DMF, sealed in a 20 mL glass bottle to obtain a mixed reactant;

[0041] (2) After ultrasonically mixing the mixed reactants for 3 min in an ultrasonic instrument, put them in an oven at 90°C for 24 hours, and then obtain {[Zn 2 (TPTA)(bpy)](CH 3 CN)(DMF) 2 } (ZnTPTA-1).

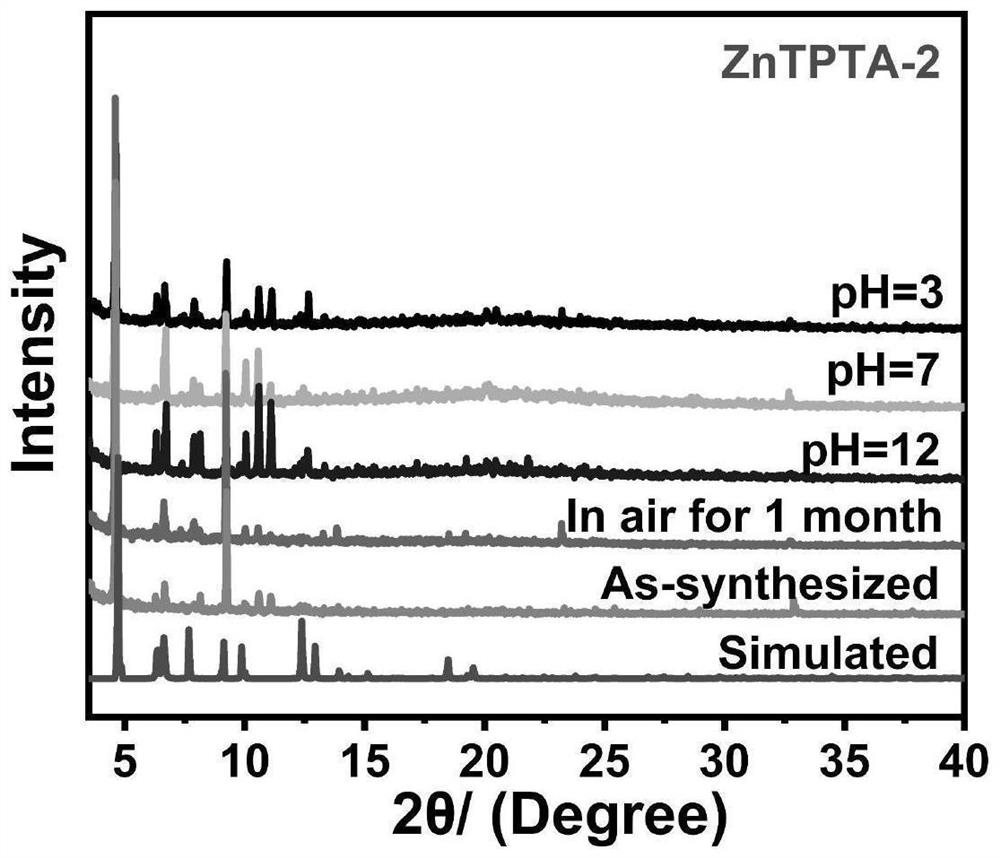

Embodiment 2

[0043] Metal-organic framework material, the chemical formula is {[Zn 4 (TPTA) 2 (H 2 O) 2 ](EtOH)(DMF) 6 };

[0044] The above {[Zn 4 (TPTA) 2 (H 2 O) 2 ](EtOH)(DMF) 6 The preparation method of } specifically comprises the following steps:

[0045] (1) Zn(NO 3 ) 3 ·6H 2 O (8 mg, 0.022 mmol), H 4 TPTA (3 mg, 0.0074 mmol), EtOH (0.5 mL) were dissolved in 1 mL DMF and 0.5 mL HNO 3 In the mixed solvent, sealed in a 20mL glass bottle to obtain a mixed reactant;

[0046] (2) Put the mixed reactants into an oven at 105°C and let them stand for 48 hours to obtain {[Zn 4 (TPTA) 2 (H 2 O) 2 ](EtOH)(DMF) 6 } (ZnTPTA-2).

Embodiment 3

[0048] Metal-organic framework material, the chemical formula is {[Zn 5 (TPTA) (trz) 6 (H 2 O) 2 ](DMF) 3 ]};

[0049] The above {[Zn 5 (TPTA) (trz) 6 (H 2 O) 2 ](DMF) 3 ]} The preparation method specifically comprises the following steps:

[0050] (1) Zn(NO 3 ) 3 ·6H 2 O (12 mg, 0.034 mmol), H 4 TPTA (3 mg, 0.0074 mmol), trz (3 mg, 0.019 mmol) were dissolved in 1.5 mL DMF and 0.4 mL HNO 3 In the mixed solvent, sealed in a 20mL glass bottle to obtain a mixed reactant;

[0051] (2) Put the mixed reactants in an oven at 90°C and let them stand for 48h to obtain {[Zn 5 (TPTA) (trz) 6 (H 2 O) 2 ](DMF) 3 ]} (ZnTPTA-3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com