Special super-tough nylon capable of being subjected to blow molding

A nylon and super-tough technology, applied in the field of blow-moldable super-tough nylon, can solve the problems of complicated preparation process of blow-mold nylon, limited use of nylon materials, poor oxidation resistance, etc., to increase recoupling ability and increase dispersion. effect, high dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A special super-tough nylon for blow molding, each component is calculated according to the mass fraction, including: 70% of PA6 resin, 29% of compatibilizer, 0.5% of amide functionalization assistant, and 0.5% of other assistants.

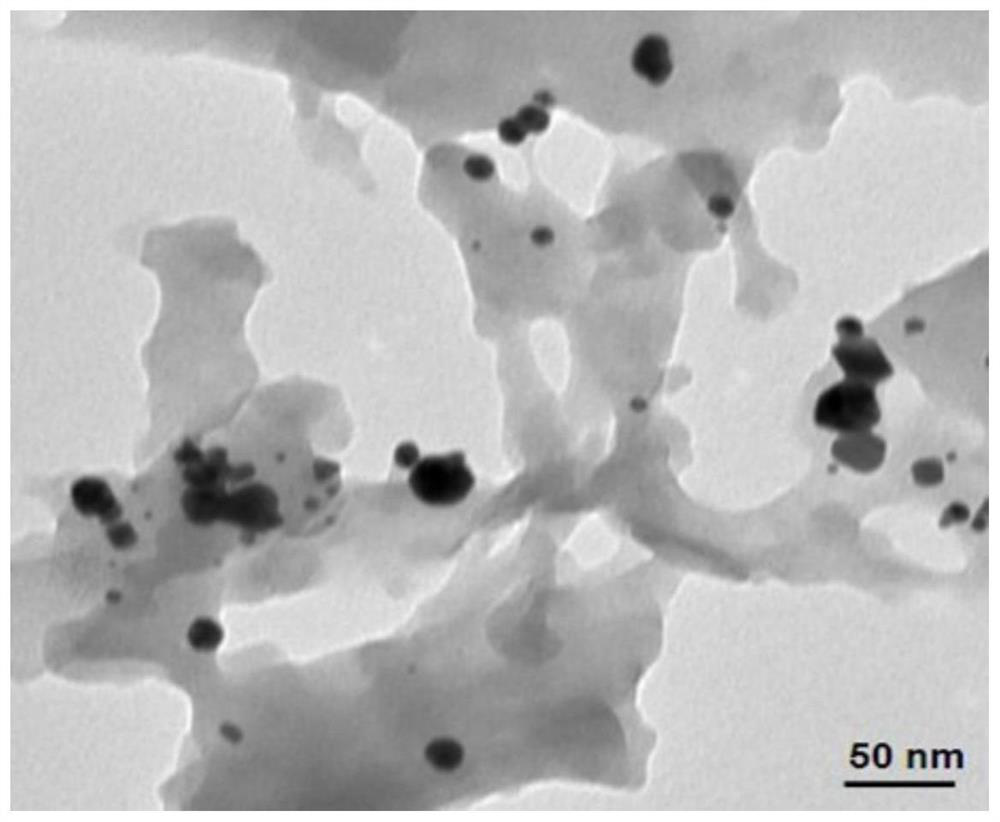

[0029] Among them, the amide functionalization assistant is loaded with SiO 2 Zn-BTC-MOF material; the compatibilizer is a commercially available POE graft material; other additives are silicone powder; PA6 is PA6 with a viscosity of 2.6;

[0030] The specific preparation method of the Zn-BTC-MOF material loaded with SiO2 is as follows:

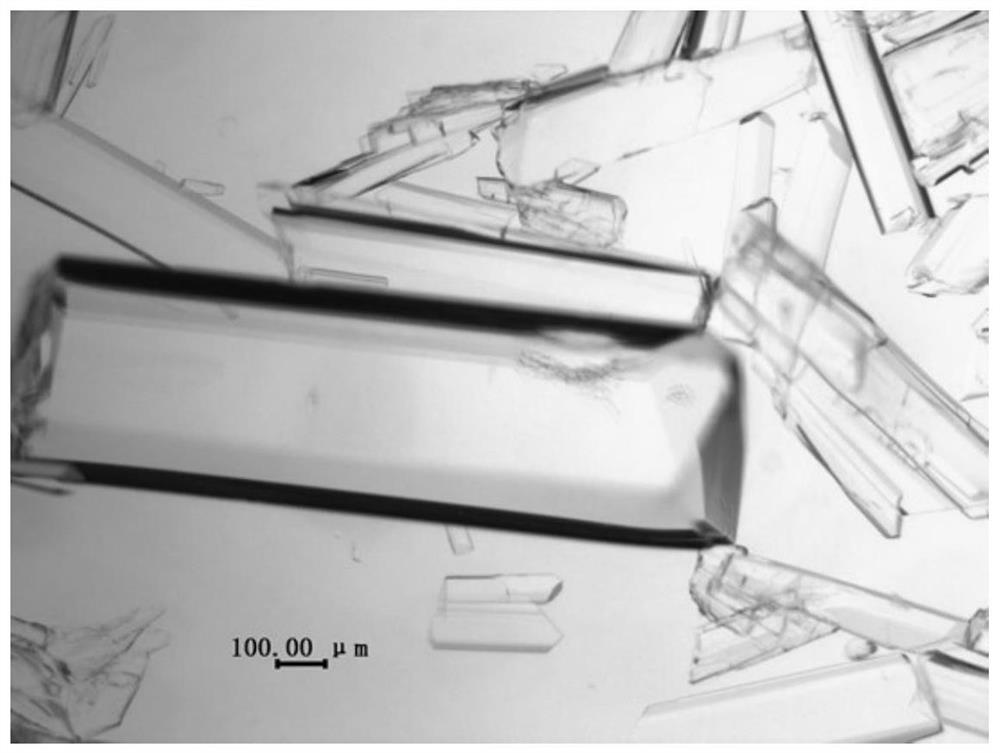

[0031] Step (1) preparation of Zn-BTC-MOF: 8 mol of trimesic acid (H 3 BTC) was completely dissolved in 100L of absolute ethanol, and 100L of water and 12mol of Zn(NO) were added under stirring at room temperature. 3 ) 2 , after the solution is clear, add 30% NaOH solution under stirring, the amount of NaOH in the NaOH solution is 24 mol, stir for 1 h, stop stirring after the reaction is completed, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com