Blue-green double-color self-luminous fiber and preparation method thereof

A self-illuminating, fiber-based technology, applied in fiber chemical characteristics, rayon manufacturing, textiles and papermaking, etc., can solve the problems of baby's eyes and perineum coverings falling, drug residues, and babies' inability to completely metabolize drugs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

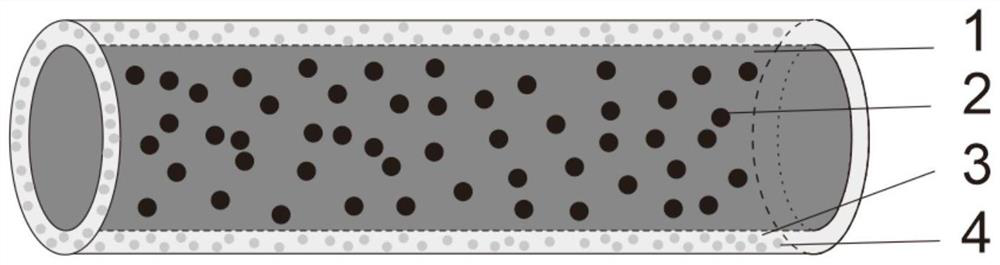

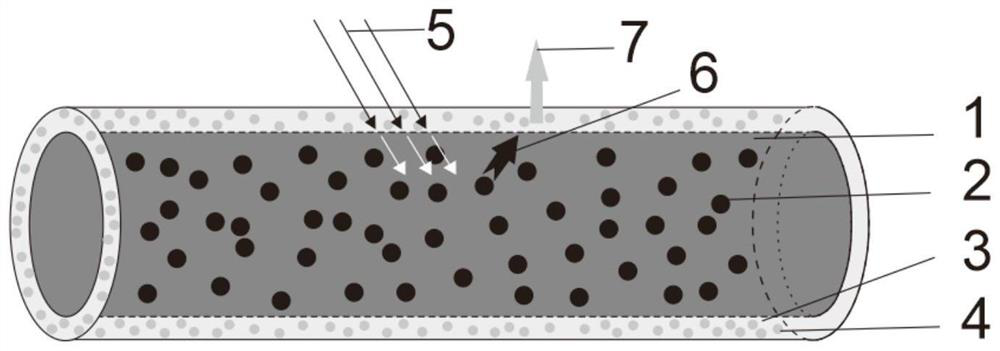

[0034] Preparation of core layer masterbatch: the polyester chips are dried and pre-crystallized, and then mixed with the rare earth strontium aluminate luminescent material according to the mass ratio of 98wt%: 2wt%, and the mixture is melted and extruded by a twin-screw extruder to prepare Core masterbatch.

[0035] Preparation of cortex masterbatch: the nylon chips are dried and pre-crystallized, and then mixed with the rare earth magnesium strontium silicate long afterglow luminescent material according to the mass ratio of 95wt%:5wt%, and the mixture is melted and extruded by a twin-screw extruder, Preparation of cortex masterbatch.

[0036]Fiber preparation and forming: add the obtained core layer masterbatch and skin layer masterbatch to the skin-core composite melt spinning machine, until the skin layer masterbatch and the core layer masterbatch are spun from the skin layer and core layer of the composite spinneret respectively. After extruding, it is merged at the ex...

Embodiment 2

[0038] Preparation of core layer masterbatch: the polyester chips are dried and pre-crystallized, and then mixed with the rare earth strontium aluminate luminescent material according to the mass ratio of 98wt%: 2wt%, and the mixture is melted and extruded by a twin-screw extruder to prepare Core masterbatch.

[0039] Preparation of cortex masterbatch: the nylon chips are dried and pre-crystallized, and then mixed with the rare earth magnesium strontium silicate long afterglow luminescent material according to the mass ratio of 95wt%:5wt%, and the mixture is melted and extruded by a twin-screw extruder, Preparation of cortex masterbatch.

[0040] Fiber preparation and forming: add the obtained core layer masterbatch and skin layer masterbatch to the skin-core composite melt spinning machine, until the skin layer masterbatch and the core layer masterbatch are spun from the skin layer and core layer of the composite spinneret respectively. After extrusion, they converge at the ...

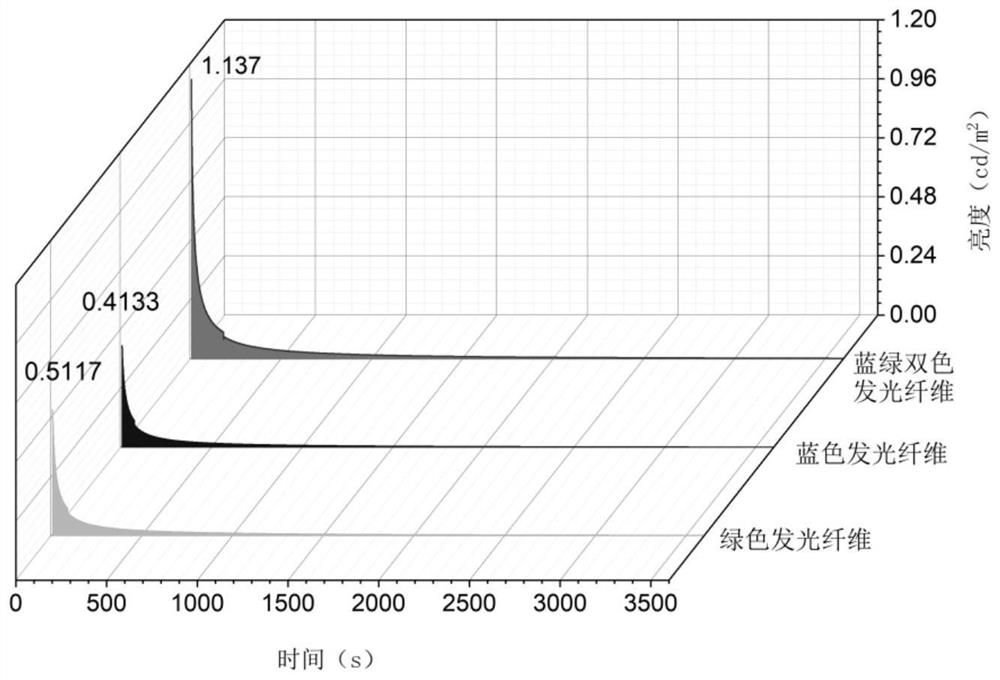

Embodiment 3

[0042] Preparation of core layer masterbatch: the polyester chips are dried and pre-crystallized, and then mixed with the rare earth strontium aluminate luminescent material according to the mass ratio of 98wt%: 2wt%, and the mixture is melted and extruded by a twin-screw extruder to prepare Core masterbatch.

[0043] Preparation of cortex masterbatch: the nylon chips are dried and pre-crystallized, and then mixed with the rare earth magnesium strontium silicate long afterglow luminescent material according to the mass ratio of 95wt%:5wt%, and the mixture is melted and extruded by a twin-screw extruder, Preparation of cortex masterbatch.

[0044] Fiber preparation and forming: add the obtained core layer masterbatch and skin layer masterbatch to the skin-core composite melt spinning machine, until the skin layer masterbatch and the core layer masterbatch are spun from the skin layer and core layer of the composite spinneret respectively. After extrusion, they converge at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com