Complex stratum pipe jacking working well and construction technology thereof

A technology of complex strata and construction technology, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve the problems of difficult precipitation, low cost, inability to precipitation, etc., and achieve the effect of simple process, improved work efficiency, and obvious water stop effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] A 330KV power pipeline project crosses the Juhe River along Chang'an Avenue, with a total length of 3380m and a pipe diameter of D2000mm, of which the lower crossing of the Juhe River is 122m long and 12m deep. The geological conditions of this section of the project are: I alluvial fan II alluvial fan, 1-2.5m of miscellaneous fill, 2.5-7m of sand and pebble layer (maximum particle size 250mm), 7-9m of silty clay, 9-12m of sand and pebble Layer (maximum particle size 100mm), 12-16m medium sand with a small amount of pebbles, 16-20m silty clay. There is groundwater 1.5m below the ground, the permeability coefficient of silty clay is 4-6m / d, the permeability coefficient of sand and pebble layer is 120m / d, and there is a beam bridge 10m to the right of the pipeline center line.

[0045] The grouting in the working well is through drilling, and then injecting cement or cement and water glass slurry 0-3m below the bottom of the hole, and the slurry squeezes out the water or ...

Embodiment 2

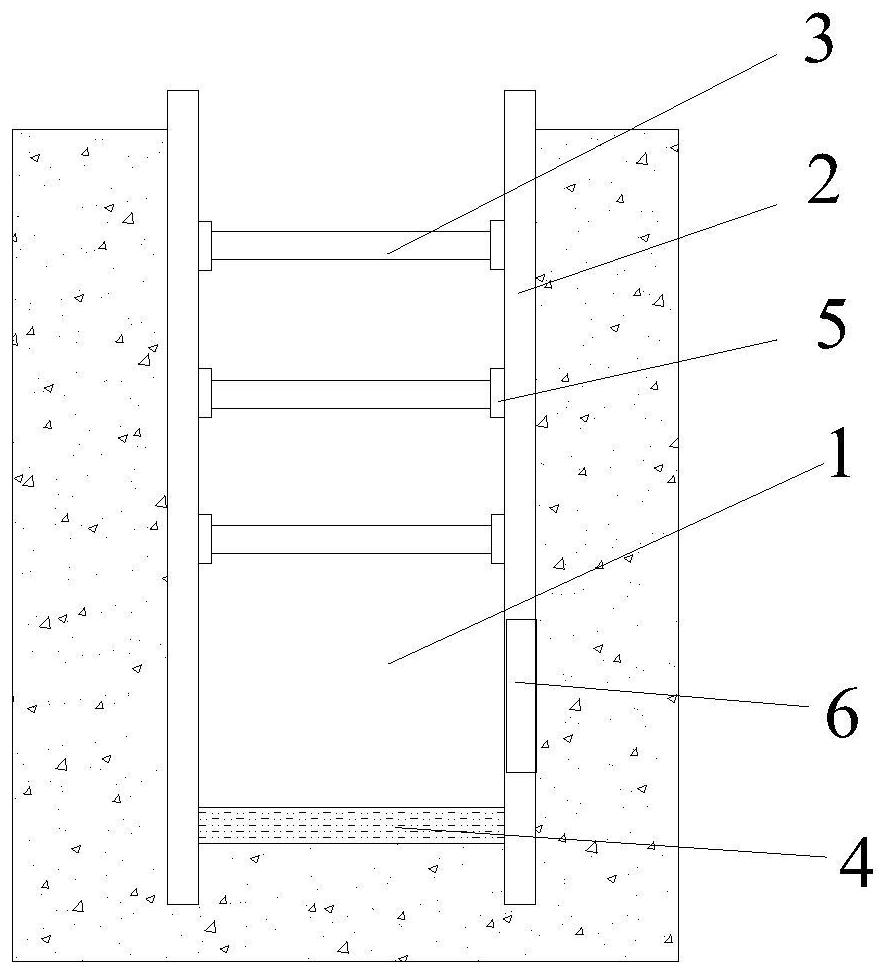

[0055] The structure of the pipe jacking working well is specifically shown in the accompanying drawings, including a working well foundation pit 1, a steel sheet pile 2, a purlin 3, and a reinforced concrete slab 4; the steel sheet pile 2 is vertically fixed on the inner wall of the working well foundation pit 1, The purlin 3 is fixedly connected to the steel sheet pile 2 through the purlin support 5; the reinforced concrete slab 4 is laid at the bottom of the well, and the steel sheet pile 2 has no hole 6 for pipe jacking, and the working well The outer periphery and bottom of the foundation pit 1 are filled with slurry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com