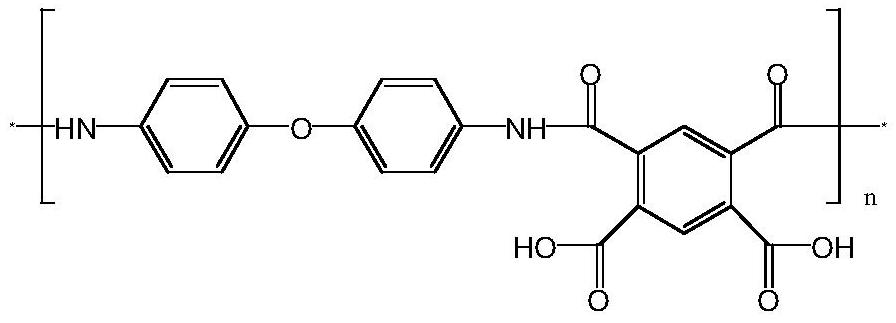

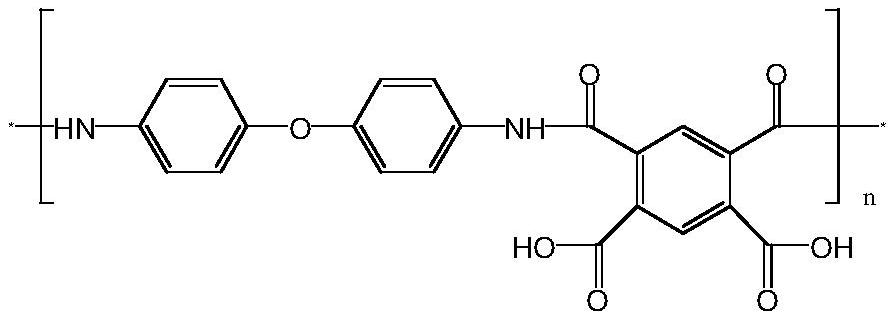

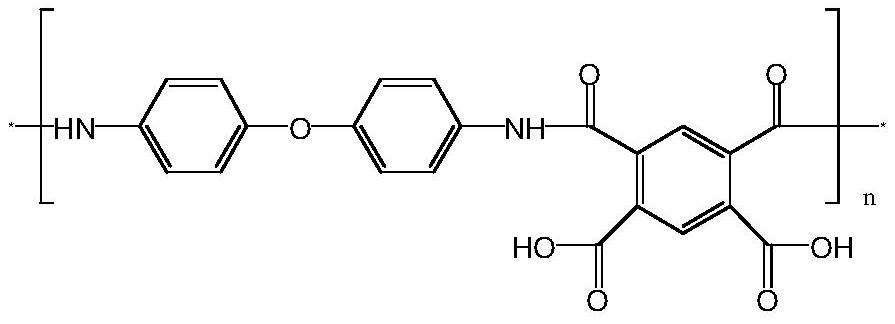

Polyimide positive photoresist based on alkali deactivation mechanism

A polyimide positive and positive photoresist technology, applied in the field of photoresist, can solve the problems of harsh temperature and time conditions, large exposure dose, and reduced production efficiency, so as to improve customer production efficiency and reduce production costs , the effect of strong photosensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The weight ratio of the components of the positive photoresist composition in this embodiment is as follows: after mixing the components, fully dissolve them with the solvent propylene glycol methyl ether acetate, and then filter them with a 0.2-micron pore size filter to obtain a positive-tone photoresist composition. In the photoresist composition, the Mw of the polyamic acid resin in this embodiment is 20,000.

[0032]

Embodiment 2

[0034] The weight ratio of the components of the positive photoresist composition in this embodiment is as follows: after mixing the components, fully dissolve them with the solvent propylene glycol methyl ether acetate, and then filter them with a 0.2-micron pore size filter to obtain a positive-tone photoresist composition. In the photoresist composition, the Mw of the polyamic acid resin in this embodiment is 20,000.

[0035]

Embodiment 3

[0037] The weight ratio of the components of the positive photoresist composition in this embodiment is as follows: after mixing the components, the solvent is fully dissolved with propylene glycol methyl ether, and then filtered with a filter membrane with a 0.2-micron pore size to obtain a positive photoresist Adhesive composition, wherein, the Mw of the polyamic acid resin in this embodiment is 20,000.

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com