Ultrasonic vibration auxiliary combustion chamber cap forming springback compensation method and system

An auxiliary combustion chamber and ultrasonic vibration technology, applied in the direction of instruments, geometric CAD, design optimization/simulation, etc., to achieve precise and controllable springback, improve mold design efficiency and pass rate, and achieve precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] like figure 1 As shown, this embodiment proposes an ultrasonic vibration-assisted combustion chamber cap forming springback compensation method, which includes:

[0034] S100. According to the forming size of the combustion chamber cap, a three-dimensional modeling software is used to construct a three-dimensional model of the forming die of the cap.

[0035] S200. According to the three-dimensional model of the forming die, use the finite element analysis and simulation software to simulate the stamping and forming process of the cap plate, predict the springback of the plate before and after the ultrasonic vibration is applied, and calculate the springback compensation factor. According to the simulation results and the obtained springback The spring compensation factor performs spring compensation for cap forming.

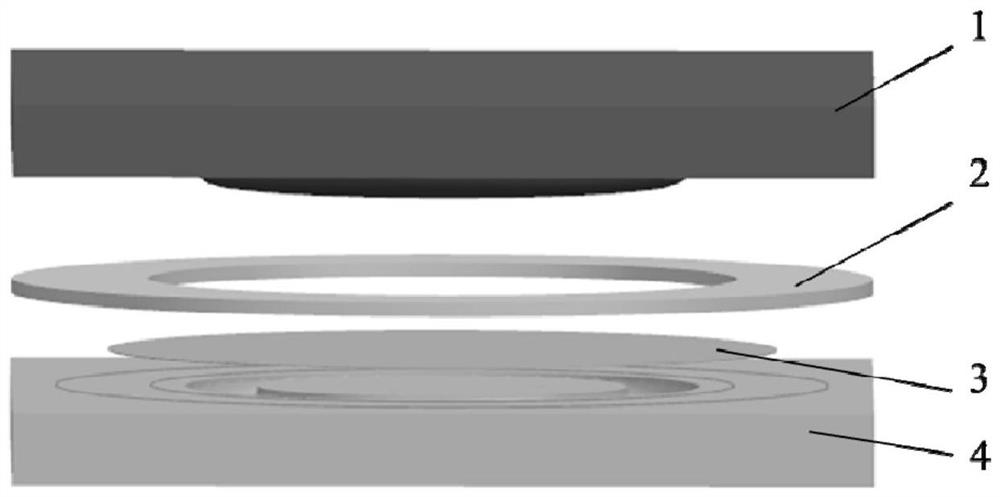

[0036] In this embodiment, the three-dimensional modeling software adopts UG12.0 design software, and the finite element analysis simulation software ad...

Embodiment 2

[0049] Corresponding to the above-mentioned Embodiment 1, this embodiment proposes an ultrasonic vibration-assisted combustion chamber cap forming rebound compensation system, which includes:

[0050] The 3D model building module of the forming die is used to construct the 3D model of the forming die of the cap by using 3D modeling software according to the forming size of the combustion chamber cap;

[0051] The forming simulation module is used to simulate the stamping and forming process of the cap plate by using the finite element analysis and simulation software according to the three-dimensional model of the forming die, predict the springback of the plate before and after applying ultrasonic vibration, and calculate the springback compensation factor. The result and the resulting springback compensation factor perform springback compensation for cap forming.

[0052] The functions performed by each component in the ultrasonic vibration-assisted combustion chamber cap fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com