Epitaxial wafer of green light emitting diode and preparation method thereof

A technology of light-emitting diodes and epitaxial wafers, which is applied to semiconductor devices, electrical components, circuits, etc., can solve the problems of uneven distribution of In components, poor uniformity of green light wavelengths, and non-concentrated light-emitting areas, so as to reduce the number of quantum wells. Effects of defects, reduction of uneven distribution of In components, and increase of distribution uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

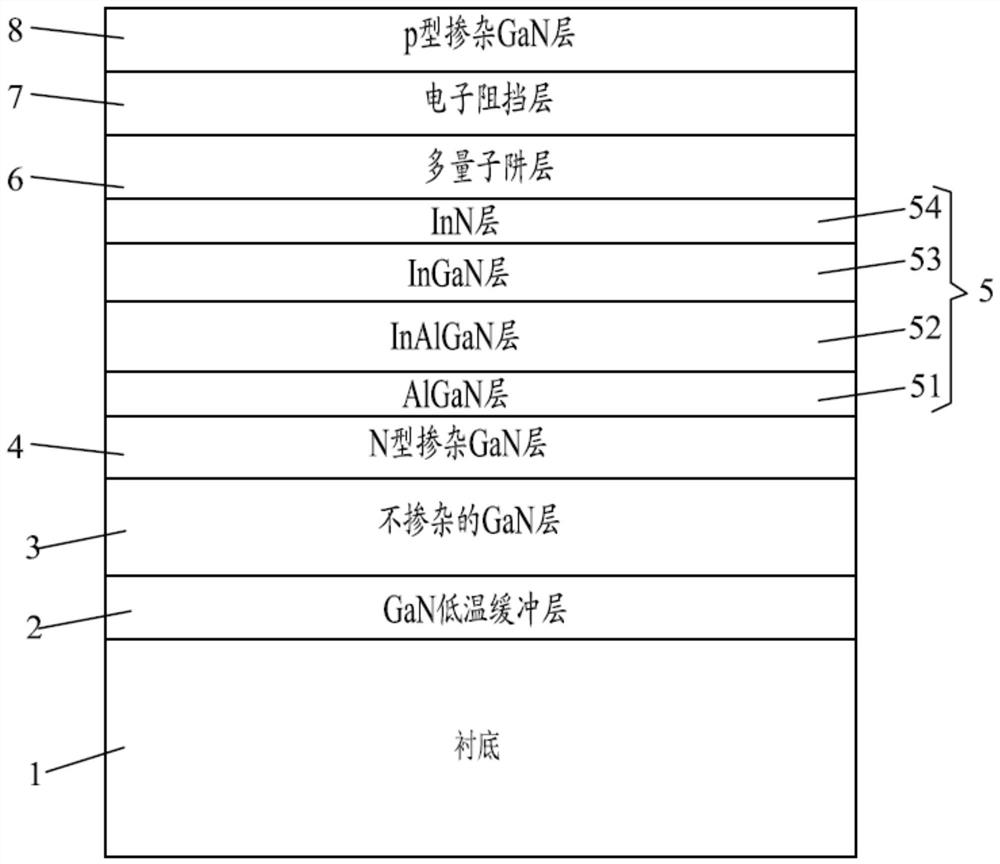

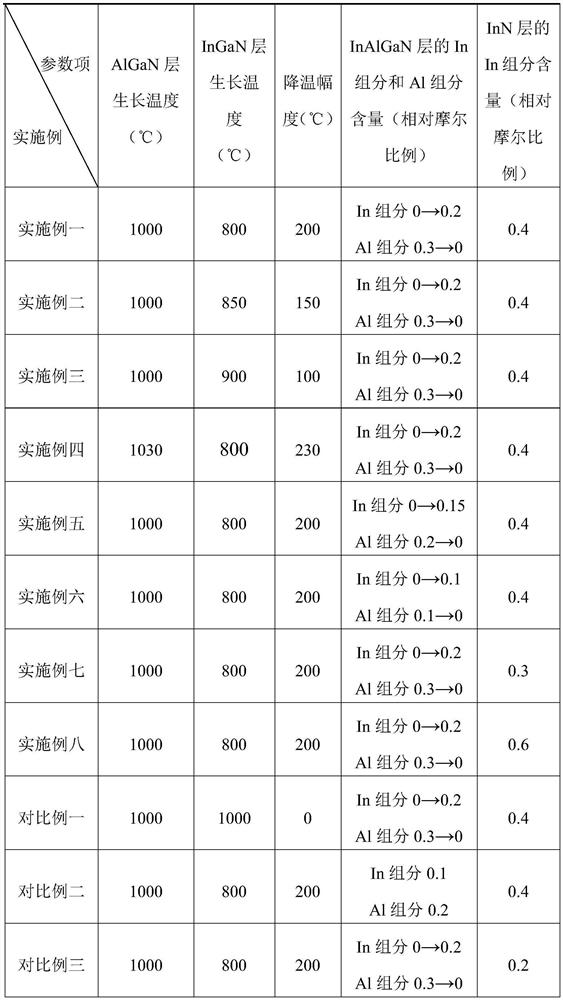

[0037] see figure 1 , shows the epitaxial wafer of the green light emitting diode in the first embodiment of the present invention, including a substrate 1, and a GaN low-temperature buffer layer 2 epitaxially grown on the substrate 1 in turn, an undoped GaN layer 3, N Type doped GaN layer 4 , multiple quantum well preparation layer 5 , multiple quantum well layer 6 , electron blocking layer 7 and p-type doped GaN layer 8 . In this embodiment, a multi-quantum well preparation layer 5 is grown before the multi-quantum well layer 6, that is, a multi-quantum well preparation layer 5 is inserted between the N-type doped GaN layer 4 and the multi-quantum well layer 6, mainly Defects inside the multiple quantum well layer are reduced by the multiple quantum well preparation layer 5, and the uniformity of the emission wavelength is improved.

[0038]Specifically, the multiple quantum well preparation layer 5 includes an AlGaN layer 51 , an InAlGaN layer 52 , an InGaN layer 53 and an...

Embodiment 2

[0068] The second embodiment of the present invention also provides an epitaxial wafer for a green light emitting diode and a preparation method thereof. The epitaxial wafer for a green light emitting diode and its preparation method in this embodiment are the same as the epitaxial wafer for a green light emitting diode in the first embodiment. The difference between and its preparation method is:

[0069] The growth temperature of the AlGaN layer is 1000°C, the growth temperature of the InGaN layer and the InN layer is 850°C, the growth temperature of the InAlGaN layer is gradually decreased from 1000°C to 850°C, and the growth temperature difference between the AlGaN layer and the InGaN layer is 150°C.

Embodiment 3

[0071] The third embodiment of the present invention also provides an epitaxial wafer for a green light emitting diode and a preparation method thereof. The epitaxial wafer for a green light emitting diode and its preparation method in this embodiment are the same as the epitaxial wafer for a green light emitting diode in the first embodiment. The difference between and its preparation method is:

[0072] The growth temperature of the AlGaN layer is 1000°C, the growth temperature of the InGaN layer and the InN layer is 900°C, the growth temperature of the InAlGaN layer is gradually decreased from 1000°C to 900°C, and the growth temperature difference between the AlGaN layer and the InGaN layer is 100°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com