Multi-power solid laser structure

A solid-state laser, multi-power technology, applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve problems such as low power is difficult to meet, power increase, complex structure, etc., achieve high fiber coupling efficiency, reduce length and volume, The effect of technical structure stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

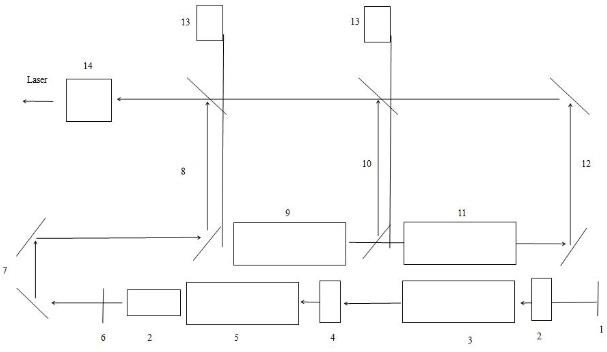

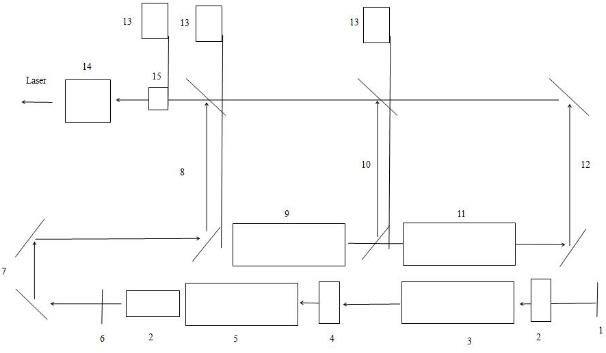

[0022] A multi-power solid-state laser structure, comprising an oscillation stage pump module I3, an oscillation stage pump module II5, a first stage amplification pump module 9, a second stage amplification pump module 11 and a coupling output mirror 14, and an oscillation stage pump module I3 It is controlled in series with the oscillation stage pump module II5 using a DC power supply, and the laser is coupled through the coupling output mirror 14 and then output through the QBH fiber.

[0023] along the laser transmission direction, such as figure 1 As shown in the direction of the middle arrow, an acousto-optic Q switch 2 and an all-reflection mirror 1 are arranged in sequence behind the oscillation stage pump module I3, and a quartz crystal is arranged between the rear of the oscillation stage pump module II5 and the front of the oscillation stage pump module I3. Optical rotation plate 4, between the front of the oscillation stage pump module II5 and the rear of the first...

Embodiment 2

[0032] The difference between this embodiment and Embodiment 1 is that, compared with Embodiment 1, in this embodiment, a frequency doubling crystal 15 is movably arranged between the coupling-out mirror 14 and the third mirror group 8 , and the frequency doubling crystal 15 is connected with an insert Motor 13.

[0033] When green light output is required, no matter 300W, 500W or 800W, the frequency doubling crystal 15 is driven by the insertion motor 13 to enter the optical path, and the laser is coupled through the coupling output mirror 14 to output green light through the optical fiber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com