Novel heating type carpet and manufacturing process thereof

A manufacturing process and heating technology, applied in carpets, textiles, papermaking, textiles, etc., can solve the problems of lack of heating effect and durability, and achieve the effect of simple, high efficiency and clear cleaning of carpets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

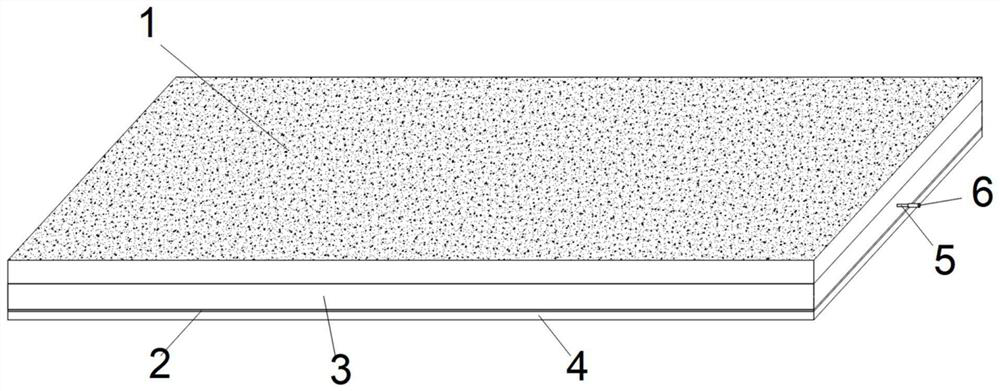

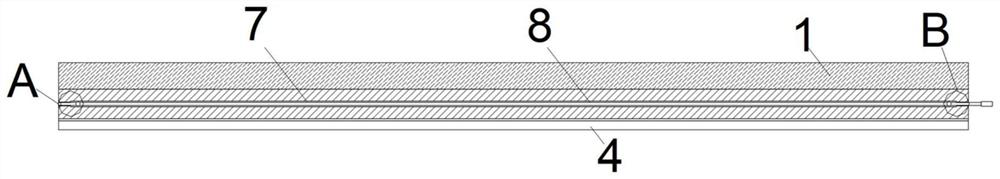

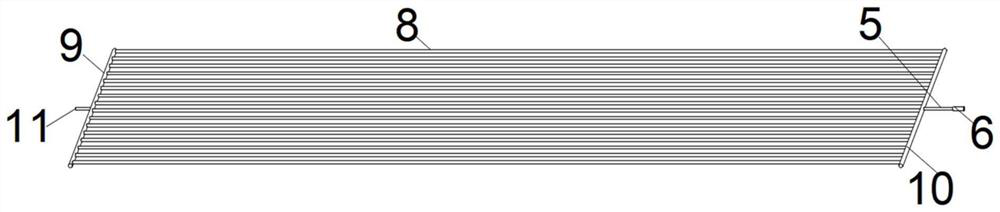

[0043] like Figure 1-5 As shown, an embodiment of the present invention provides a novel heating type carpet and a manufacturing process thereof, comprising the following steps:

[0044] S1. Raw material preparation

[0045] Prepare a certain amount of wool, nylon, polyester, cotton, and clean them;

[0046] S2. Blueprint Design

[0047] According to the different positions of the carpet, design the corresponding size carpet drawings, and then make blueprints according to the drawings;

[0048] S3. Staining preparation

[0049] According to the design draft, the yarn of the raw material is dyed into the corresponding color, and the dyed colored yarn is plied and wrapped into a ball for use in blanket weaving;

[0050] S4. Tool preparation

[0051] Have rakes, knives, scissors, looms, muskets ready for use;

[0052] S5. Hanging scriptures on a rack

[0053] Build a loom of the corresponding size according to the size of the blueprint, and then tie the warp to the loom a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com