Method for improving grade of potassium chloride and application

A potassium chloride and grade technology, which is applied in the field of separation and purification, can solve the problems of high stability of raw ore properties, lower potassium chloride grade, strict operating conditions, etc., and achieve a simple and feasible regulation method, good regulation and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

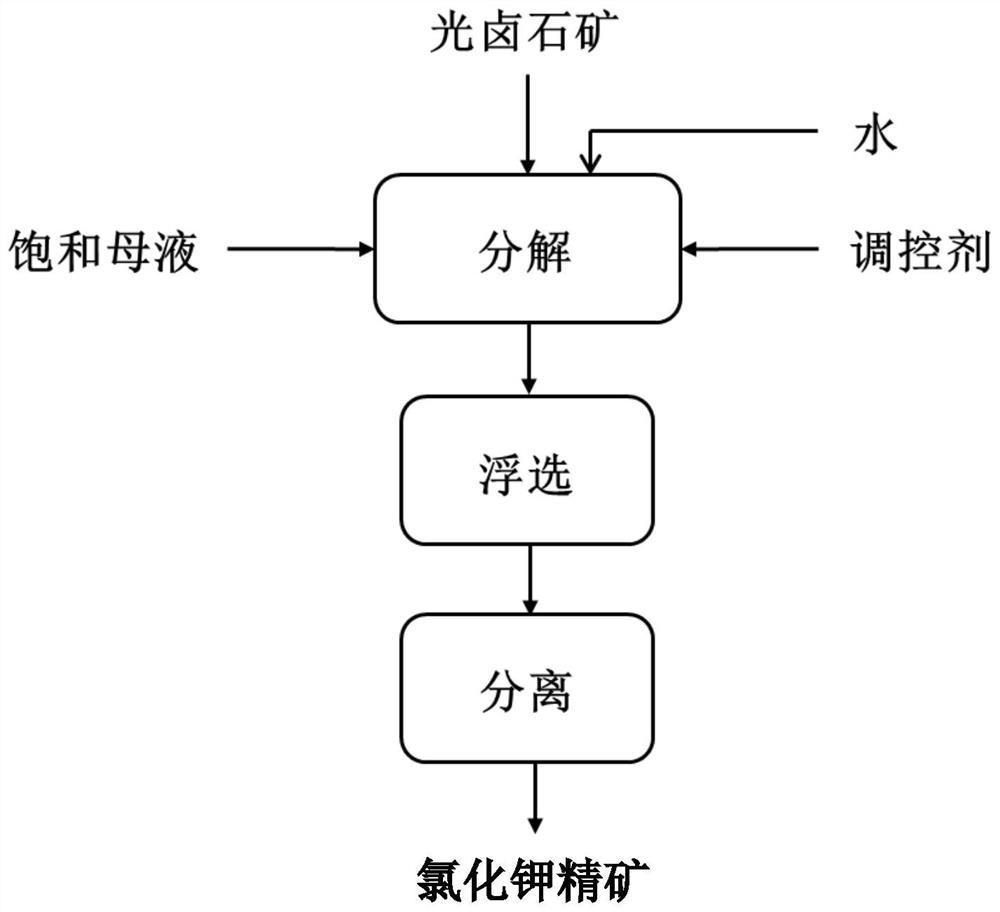

Image

Examples

preparation example Construction

[0021] In some preferred embodiments, the preparation method includes: dissolving a regulator in a saturated mother liquor to form a first mixed solution, and then slowly adding carnallite and water to the first mixed solution for decomposition treatment to obtain an intermediate product.

[0022] In the present invention, the mode of adding the regulator can be solid added or added as a solution.

[0023] In the present invention, the addition of the regulating agent is not limited to the saturated mother liquor, and can also be added to fresh water or other substitute fresh water.

[0024] Further, the time of the decomposition treatment is 10-20 min, and the temperature is 15-25°C.

[0025] Further, the preparation method further includes: after the decomposition treatment is completed, the obtained mixture is allowed to stand for 10-20 minutes.

[0026] In some preferred embodiments, the carnallite includes sodium-containing carnallite.

[0027] Further, the carnallite i...

Embodiment 1

[0043] 330 mL of saturated mother liquor required for the configuration and decomposition of carnallite (saturated mother liquor includes the following components calculated by mass percentage: KCl 3.0wt%, NaCl 0.05wt%, MgCl 2 26.0wt%, H 2 O 70.95wt%. ), then weigh 0.35 g of 1# regulator (composed of polyethylene glycol-800 and polyacrylamide 1:1), add it to the saturated mother liquor and stir well until it is completely dissolved. Continue stirring, control the feeding speed, add 500 g of sodium-containing carnallite (sodium chloride content of 30%) and a certain amount of fresh water synchronously and slowly to the saturated mother liquor to decompose at 20° C. The decomposition time is 10 min. After the decomposition is completed, continue to balance for 10 minutes, for a total of 20 minutes. Then the wet material is transferred to the flotation cell for flotation. After roughing, sweeping and beneficiation, the potassium chloride grade in the obtained concentrate is inc...

Embodiment 2

[0045] Prepare 330 mL of saturated mother liquor required for decomposing carnallite, then weigh 0.32 g of 2# regulator (polyethylene glycol-800), add it to the saturated mother liquor and fully stir until completely dissolved. Continue stirring, control the feeding speed, add 500 g of sodium-containing carnallite (sodium chloride content is 30%) and a certain amount of fresh water synchronously and slowly to the saturated mother liquor to decompose at 20° C. The decomposition time is 15min. After the decomposition is completed, continue to equilibrate for 15 minutes, for a total of 30 minutes. Then the wet material is transferred to the flotation cell for flotation. After roughing, sweeping and beneficiation, the potassium chloride grade in the obtained concentrate is increased from 80.73% before adding the regulator to 88.55%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com