A method for selectively recovering antimony, arsenic and alkali from arsenic-alkali slag

An arsenic-alkali slag and selective technology, applied in chemical instruments and methods, alkali metal carbonates, alkali metal compounds, etc., can solve the problems of comprehensive recycling and utilization methods without arsenic-alkali slag, and achieve the benefits of production efficiency and purity. High and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In this embodiment, secondary alkali arsenic slag is used as the raw material, and its composition is shown in Table 1.

[0037] The composition of the secondary alkali arsenic residue in the embodiment 1 of table 1

[0038] element O F Na Mg Al Si P S Cl Element(%) 26.80 0.15 24.45 0.316 1.81 3.34 0.59 3.205 0.586 element K Ca Sc Ti Cr Mn Fe Cu Zn Element(%) 0.303 1.32 0.079 0.137 0.0419 0.0176 1.665 0.008 0.173 element As Se Rb Sr Zr In Sb Pb other Element(%) 4.185 0.2155 0.002 0.0076 0.0059 0.013 7.36 0.036 23.1835

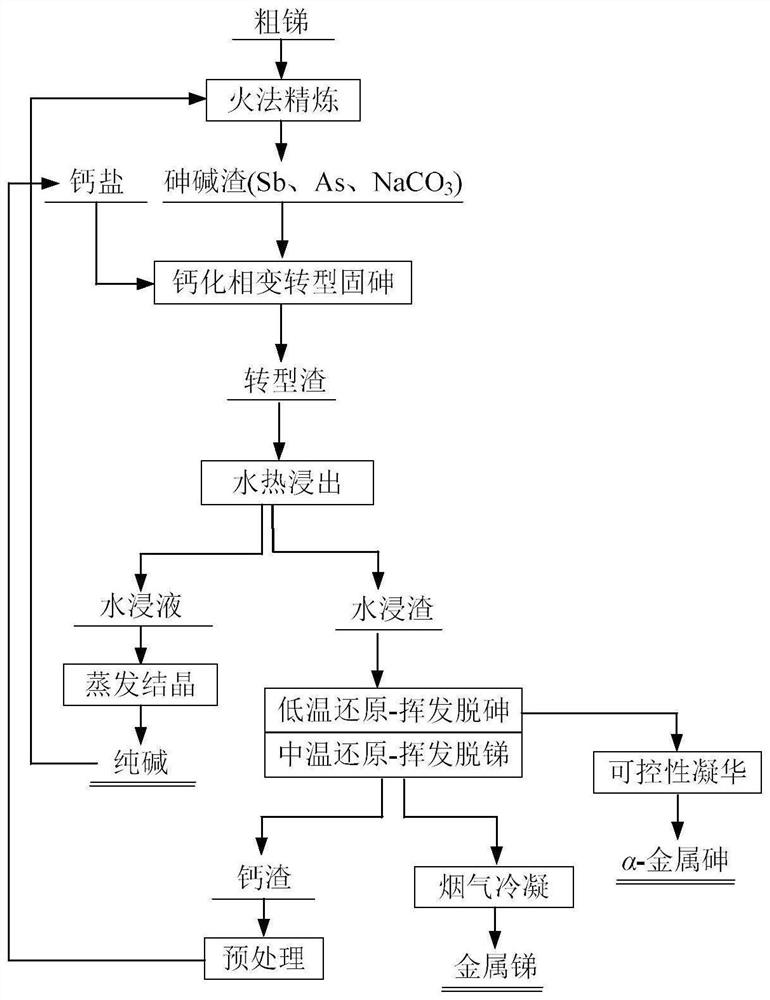

[0039] A method for selectively recovering antimony, arsenic and alkali from arsenic-alkali slag according to the present invention, the process flow diagram of which is as follows: figure 1 shown, including the following steps:

[0040] (1) grinding the arsenic-alkali slag with a ball mill, and then sieving the arsenic-alkali slag with a particle...

Embodiment 2

[0047] In this embodiment, secondary alkali arsenic slag is used as raw material, and its composition is shown in Table 2.

[0048] The composition of the secondary alkali arsenic slag in the embodiment 2 of table 2

[0049] element O F Na Mg Al Si P S Cl Element(%) 24.32 0.21 27.78 0.423 1.56 2.7 0.34 2.956 0.378 element K Ca Sc Ti Cr Mn Fe Cu Zn Element(%) 0.563 1.87 0.0365 0.125 0.0369 0.0132 1.789 0.0056 0.23 element As Se Rb Sr Zr In Sb Pb other Element(%) 6.987 0.334 0.005 0.0065 0.0036 0.032 9.86 0.024 17.4117

[0050] A method for selectively recovering antimony, arsenic and alkali from arsenic-alkali slag of the present invention comprises the following steps:

[0051] (1) grinding the arsenic-alkali slag with a ball mill, and then sieving the arsenic-alkali slag with a particle size of 30-100 μm through a vibrating screen;

[0052] (2) get 30g of alkali arse...

Embodiment 3

[0058] The raw materials of alkali arsenic slag treated in this example are the same as those in Example 1.

[0059] A method for selectively recovering antimony, arsenic and alkali from arsenic-alkali slag of the present invention comprises the following steps:

[0060] (1) The arsenic-alkali slag is ground with a ball mill, and then the slag with a particle size of 30-100 μm is sieved through a vibrating screen;

[0061] (2) get 30g of alkali arsenic slag after step (1), utilize gravity separator to carry out gravity separation, obtain gravity separation tailings and antimony slag;

[0062] (3) Place the gravity tailings and calcium chloride in a molar ratio of 1:1.2 in a grinding crucible for mixing and grinding for 1 hour, place the ground mixed sample in a corundum crucible, and then put the corundum crucible into a tubular The calcification transformation was carried out in the atmosphere furnace, and the parameters were set as: heating time 180min, reaction temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com