Method for extracting thuja sutchuenensis essential oil by utilizing steam distillation method

A technology of steam distillation and thuja essential oil, which is applied in essential oils/fragrances, resistance to vector-borne diseases, and fat production. It can solve the problems of unfavorable resource utilization, branches and leaves that can only be discarded, etc., and achieve low cost and volatile oil. The effect of many ingredients and high extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

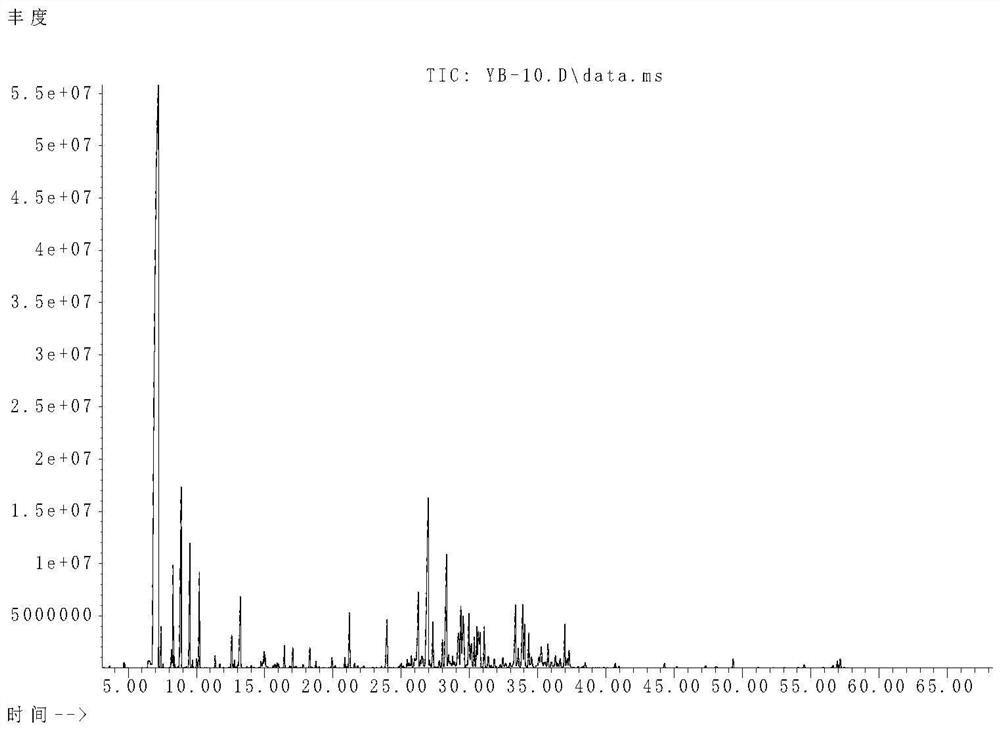

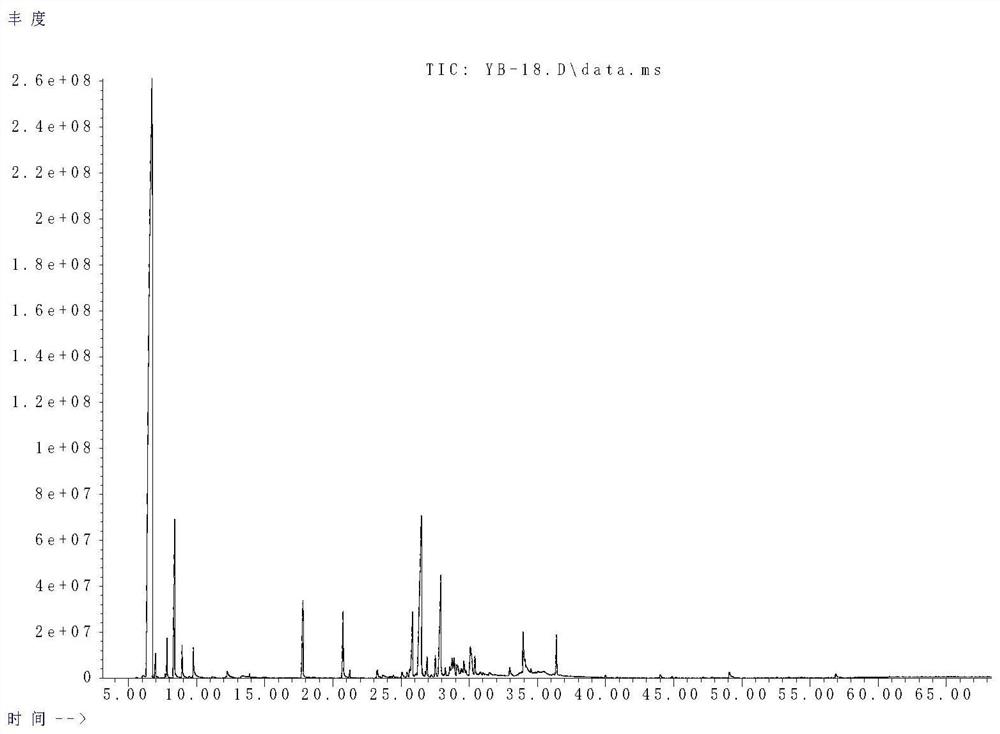

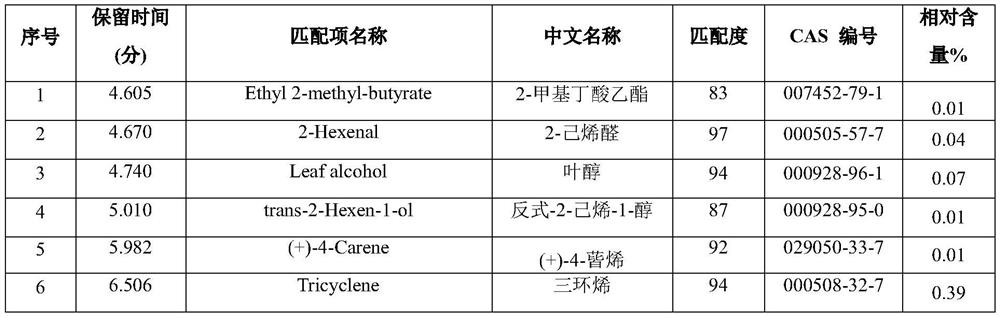

Image

Examples

Embodiment 1

[0033] The method that utilizes steam distillation to extract Thuja essential oil provided by this application comprises the steps:

[0034] 1) Material collection, transportation and storage: Collect the waste branches and leaves generated during the production of cuttings, store them in an insulating foam box, transport them to the production base, cut off the small branches and leaves, and seal them at low temperature (2-6°C) for future use;

[0035] 2) Raw material pretreatment: take refrigerated thuja branches and leaves and place them in a cool and ventilated place to turn and air for 2 hours, until the water content of the branches and leaves drops to 81% of the natural water content, and all the branches and leaves are free of water;

[0036] 3) powdering: after the dried branches are cut into small sections of 2-5cm, pulverize with a traditional Chinese medicine powdering machine for 15s to obtain thuja powder with a particle size of 10-30 objects;

[0037] 4) Water d...

Embodiment 2

[0040] The method that utilizes steam distillation to extract Thuja essential oil provided by this application comprises the steps:

[0041] 1) Material collection, transportation and storage: prune the small branches in the central part of the thuja canopy with dense branches and leaves, so as to achieve good ventilation and not change the overall shape of the crown, and store them in a thermal insulation foam box. Branches and leaves, sealed and stored at low temperature (2-6°C) for later use;

[0042] 2) Raw material pretreatment: Take the thuja branches and leaves preserved in cold storage and place them in a cool and ventilated place to turn and dry for 1 hour, until the water content of the branches and leaves drops to 85% of the natural water content, and all the branches and leaves are free of water;

[0043] 3) powdering: after the dried branches are cut into small sections of 2-5cm, pulverize with a traditional Chinese medicine powdering machine for 10s to obtain a t...

Embodiment 3

[0047] The method that utilizes steam distillation to extract Thuja essential oil provided by this application comprises the steps:

[0048] 1) Material collection, transportation and storage: prune the small branches in the middle of the thuja canopy with dense branches and leaves, so as to achieve good ventilation and not change the overall shape of the crown. Branches and leaves, sealed and stored at low temperature (2-6°C) for later use;

[0049] 2) Raw material pretreatment: take refrigerated thuja branches and leaves and place them in a cool and ventilated place for 3 hours, until the water content of the branches and leaves drops to 75% of the natural water content, and all the branches and leaves are free of water;

[0050] 3) powdering: after the dried branches are cut into small sections of 2-5cm, pulverize with a traditional Chinese medicine powdering machine for 20s to obtain thuja powder with a particle size of 10-30 objects;

[0051] 4) Water distillation: add wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com