Power station water vapor multi-parameter cooperative measurement system and measurement method

The technology of a measurement system and measurement method is applied in the field of water vapor multi-parameter collaborative measurement system in power stations, which can solve the problems of pH electrodes needing to be replaced regularly, poor pH measurement accuracy, and high operation and maintenance costs, so as to improve measurement accuracy and intelligence, Safe operation, energy saving, consumption reduction, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

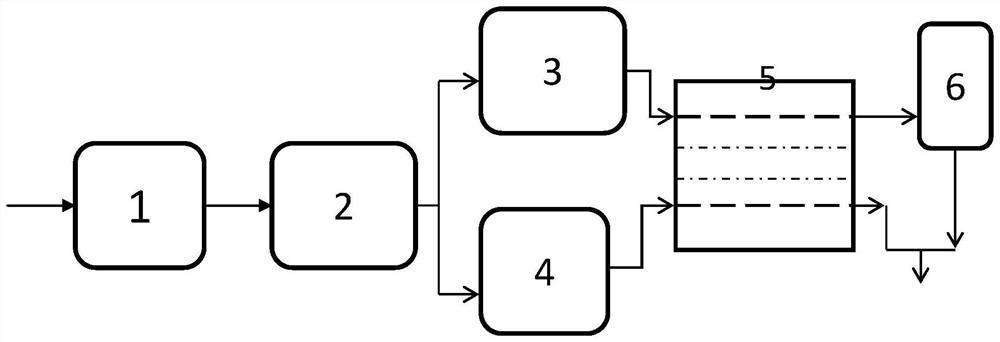

[0044] see figure 1 The present invention provides a multi-parameter collaborative measurement system for water vapor in a power station, including a water sample inlet, a water sample outlet, a first conductivity sensor 1, a cation removal device 2, a second conductivity sensor 3, a desalination device 4, a membrane exchange device 5 and the third conductivity sensor 6; the water sample inlet communicates with the cation removal device 2 through the first conductivity sensor 1; the cation removal device 2 communicates with the second conductivity sensor 3 and the desalination device 4 respectively; the second The conductivity sensor 3 and the desalination device 4 are connected to the membrane exchange device 5; the outlet of the membrane exchange device 5 communicates with the water sample outlet; the membrane exchange device 5 communicates with the water sample outlet through the third conductivity sensor 6.

[0045] The cation removal device 2 is a continuous electric rege...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com