Hydrogen-doped gas combustion test platform

A gas combustion and testing platform technology, which is applied in chemical analysis by combustion, hydrogen technology, measuring devices, etc., can solve problems such as the difficulty in testing the combustion performance of hydrogen-doped gas, and achieve a small footprint, high safety factor, and flexible use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

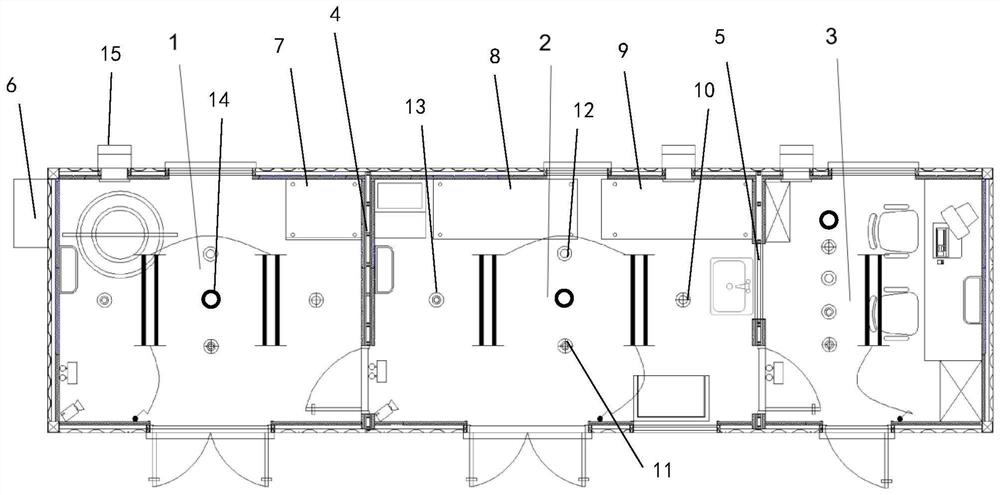

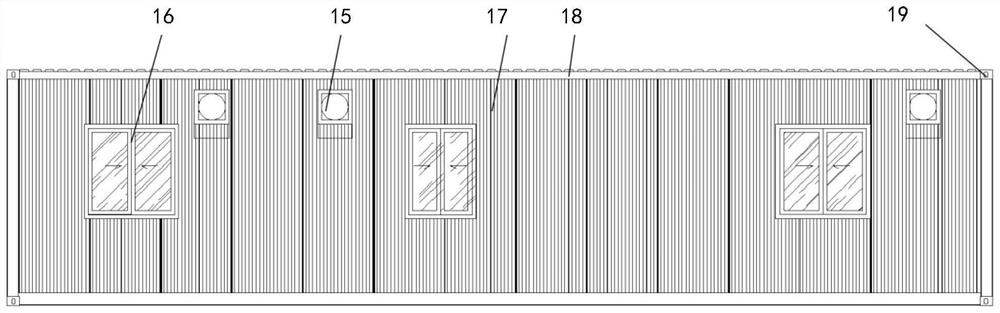

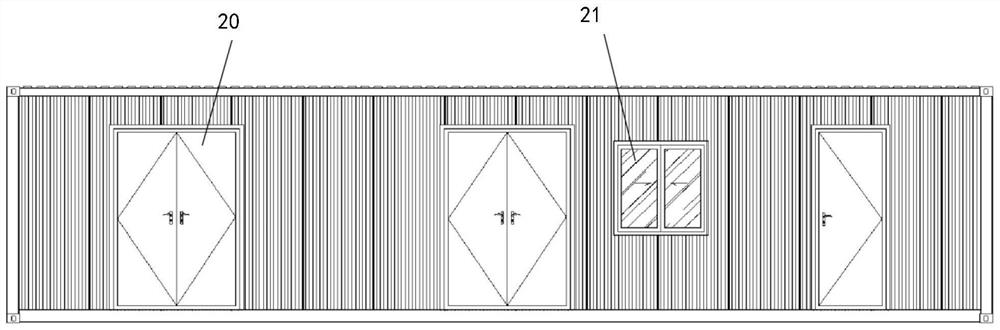

[0046] A hydrogen-doped gas combustion test platform, such as figure 1 and Figure 8 shown, including: distribution room 1, test room 2 and office room 3;

[0047] Among them, the gas distribution room 1 and the test room 2 are separated by the first explosion-proof wall 4, and the test room 2 and the office room 3 are separated by the second explosion-proof wall 5; the gas distribution room 1, the test room 2 and the office room 3 are equipped with explosion-proof monitoring devices; an explosion-proof gas cylinder cabinet 6 is installed on the outside of the gas distribution room 1; the explosion-proof gas cylinder cabinet 6 is connected to the gas mixing cabinet 7 in the gas distribution room 1 through pipelines; The gas cooker comprehensive performance testing system 8 in 2 is connected to the gas water heater comprehensive performance testing system 9 .

[0048] The explosion-proof monitoring device includes interlinked explosion-proof smoke alarm 10, explosion-proof hydr...

Embodiment 2

[0057] A method for determining the combustion heat load of hydrogen-doped gas, comprising:

[0058] S1, igniting the gas appliances in the comprehensive performance testing system 8 of the gas cooker and the comprehensive performance testing system 9 of the gas water heater;

[0059] S2. Use the gas flow meter to measure the gas flow rate within the period of 15 to 20 minutes after the burning appliance is ignited. The gas flow meter pointer travels the number of full circles for more than one week, and the measurement time should be no less than 1 minute;

[0060] S3. Repeat the measurement twice or more, and when the error of the two consecutive measurement results is less than 2%, calculate the average value of the two measurement results;

[0061] S4. According to the average value of the measurement results in S3, the heat load of the combustion of the hydrogen-doped gas is obtained. For example, the measured heat load of gas is obtained through GB16410-2020.

[0062] ...

Embodiment 3

[0064] A method for measuring the thermal efficiency of combustion of hydrogen-doped gas, comprising:

[0065] S1. Light the water heater in the gas water heater comprehensive performance test system 9 for 15 minutes, and then pour in tap water, start measuring the gas consumption, and record all parameters;

[0066] S2, ignite the cooker in the comprehensive performance test system 8 of the gas cooker for 15 minutes and put it on the test pot;

[0067] S3, set the initial temperature of the water in the test pot as room temperature plus 5°C, and the final temperature of the water as the initial temperature of the water plus 30°C;

[0068] S4. When the temperature of the water in the test pot is 5°C before the initial temperature, start stirring, and start measuring gas consumption when it reaches the initial temperature; start stirring again when the temperature is 25°C higher than the initial temperature, and turn off when the temperature is 30°C higher than the initial temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com